Field operation safety management method and system for operation and maintenance of power distribution network

A technology for on-site operation and safety management, applied in information technology support systems, image data processing, data processing applications, etc., can solve the problems of wasting manpower, unable to carry on-site staff, unable to issue warnings in time, etc., to facilitate reference, improve The effect of safety and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

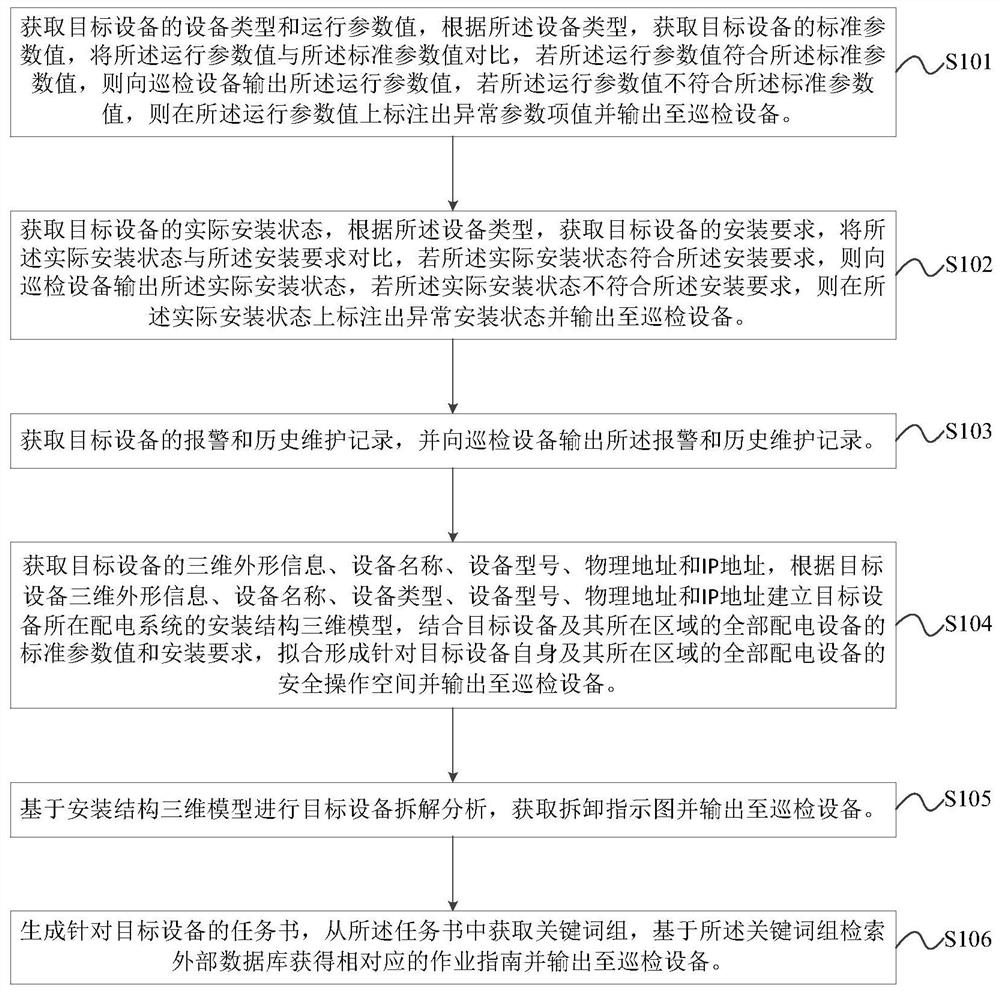

[0049] Such as figure 1 As shown, it is a flowchart of a field operation safety management method for distribution network operation and maintenance provided by the embodiment of the present application. The field operation safety management method for distribution network operation and maintenance includes steps S101 to Step S106.

[0050] Step S101, obtain the device type and operating parameter value of the target device, obtain the standard parameter value of the target device according to the device type, compare the operating parameter value with the standard parameter value, if the operating parameter value meets the specified If the above standard parameter value is specified, then the operation parameter value will be output to the inspection equipment. If the operation parameter value does not meet the above standard parameter value, the abnormal parameter item value will be marked on the operation parameter value and output to the inspection equipment. equipment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com