Device and method for detecting warping degree of wafer

A warpage and position detection technology, which is applied in the field of warpage devices, can solve problems such as scratches or collisions, increased deviation of test result data, and inability to detect wafer warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

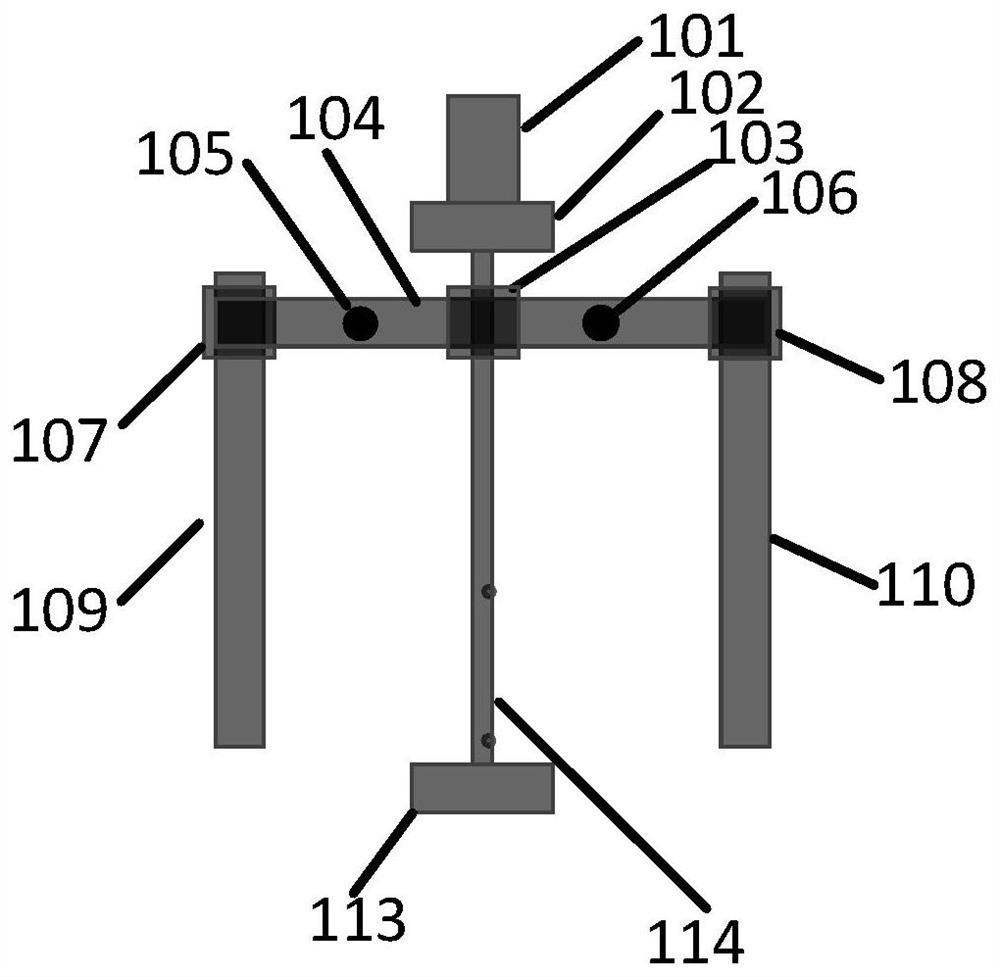

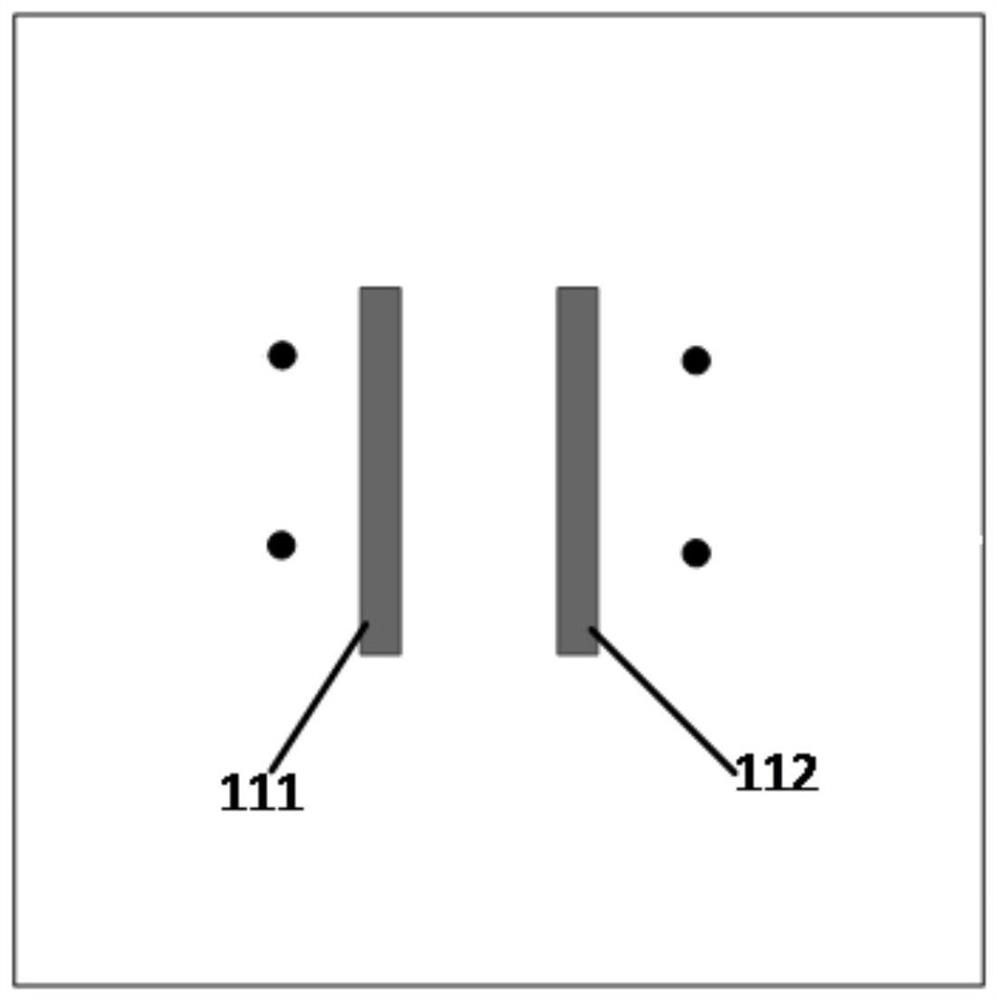

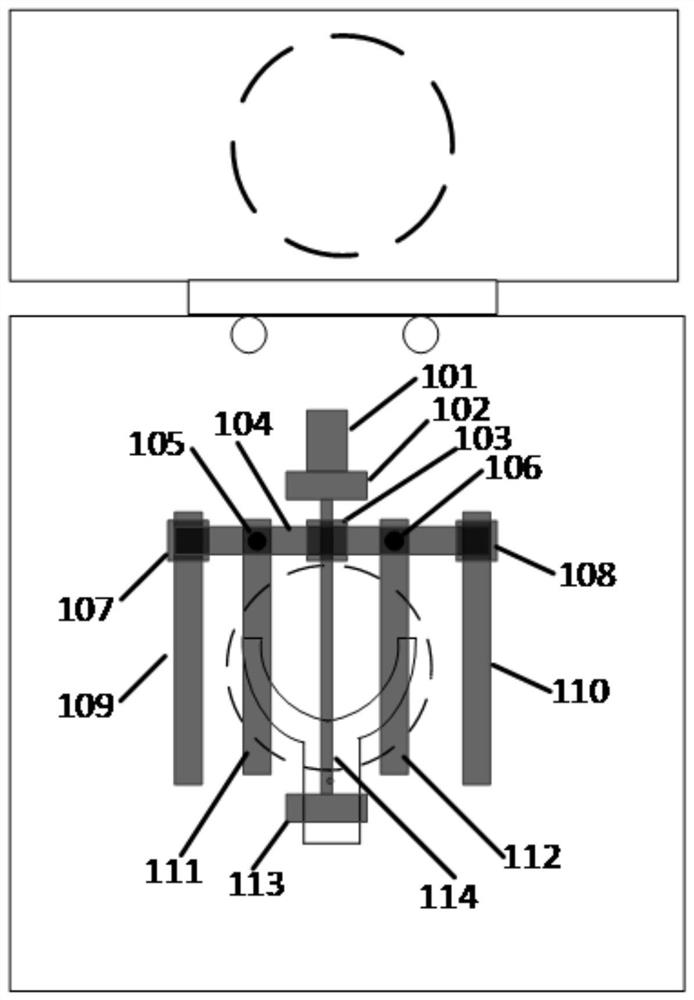

[0109] Such as Figure 1 to Figure 4 As shown, the present invention provides a device for detecting the warpage of a wafer. The wafer is placed on a carrier device in a transport chamber. The detection device includes a beam 104, a pair of distance measuring sensors 105, a driving device and Processor; where,

[0110] The beam 104 is arranged on the upper cover of the transmission chamber, and a pair of ranging sensors 105 are arranged on the beam 104;

[0111] The driving device is used to drive the crossbeam 104 to move in the horizontal direction relative to the plane where the wafer is located, and drive the ranging sensor 105 to move to detect the distance between the detection end of the ranging sensor 105 and the wafer;

[0112] The processor is used to calculate the warpage of the wafer according to the distance detected by the pair of distance measuring sensors 105, and give an alarm when the warpage exceeds a preset deviation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com