Fragrance spraying and humidity controlling device for semen trichosanthis processing

A melon seed and fragrance spraying technology, which is applied in the fields of application, separation of solids from solids by air flow, food science, etc., can solve the problems of uneven fragrance spraying, inconvenient operation of humidity control, etc., and achieves good fragrance spraying effect and uniform adhesion. And comprehensive and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

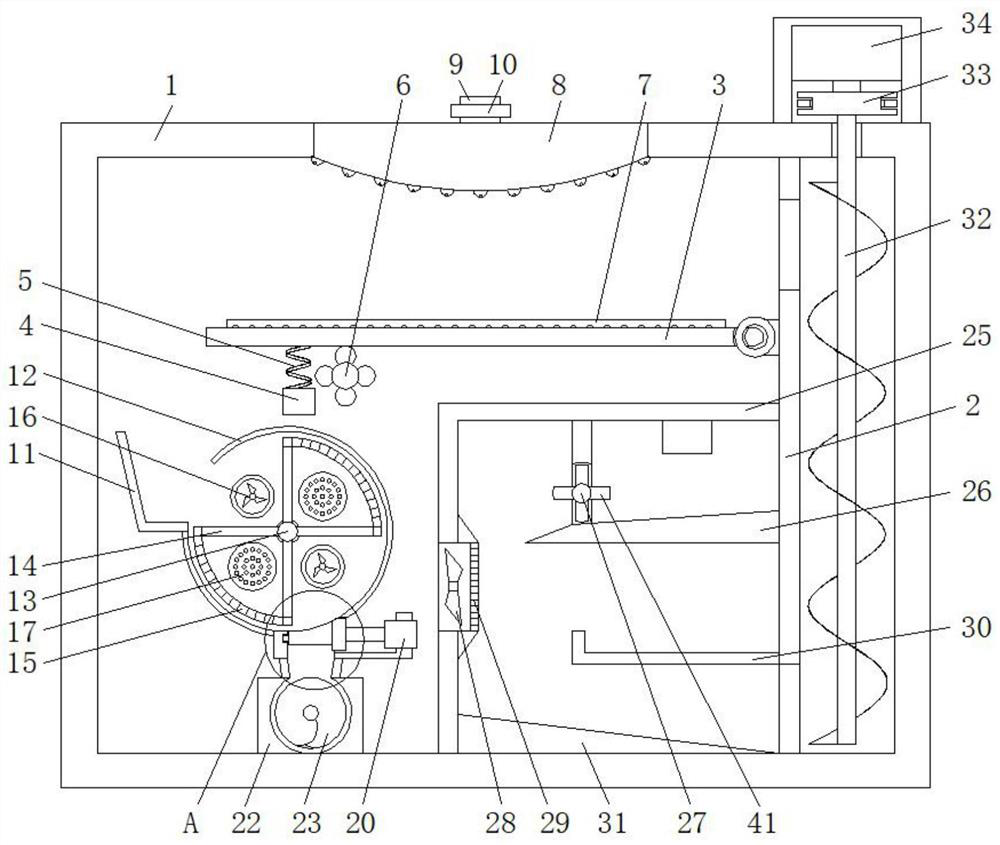

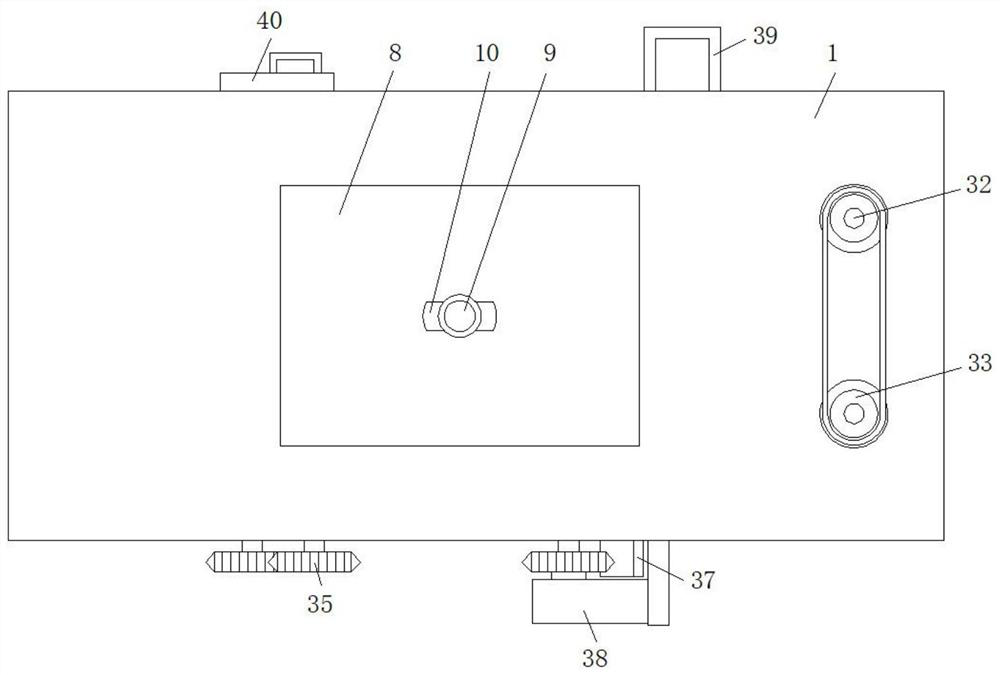

[0032] refer to Figure 1-4, a fragrance spraying and humidity control device for the processing of Trichosanthes seeds, comprising a working box 1, the inner side of the working box 1 is provided with a winnowing and shelling mechanism, a comprehensive fragrance spraying mechanism and a uniform humidity control mechanism, the comprehensive fragrance spraying mechanism includes a feeding partition 2, Vibrating plate 3, vibrating roller 6, liquid storage spray head 8 and liquid inlet valve 10, uniform humidity control mechanism includes material guide plate 11, turning cylinder 12, rotating shaft 13, fan 16, sprayer 17, discharge screw shaft 23 and Cylinder 20, winnowing shelling mechanism comprises winnowing box 25, rotating shaft two 27, fan 28, waste material groove plate 30, inclined plate 31 and rotating plate 41; Between the inner walls, and one side of the feeding partition 2 is provided with a feeding assembly, the feeding assembly includes a feeding screw shaft 32, the...

Embodiment 2

[0035] Such as Figure 1-4 As shown, the present embodiment is basically the same as Embodiment 1, and the more optimized place is that the winnowing box 25 in the winnowing and shelling mechanism is fixedly connected to one side of the material feeding dividing plate 2, and the inside of the winnowing box 25 is fixedly arranged There is a material storage partition 26, the rotating shaft two 27 is arranged on one side of the plate body of the storage material partition 26, and the rotating plate 41 is provided with several and is dispersed and fixedly connected to the outside of the shaft body of the rotating shaft two 27, and the fan 28 is installed on the air separation In the side wall of case 25, and fan 28 is fixedly connected with filter plate 29 near the side of rotating plate 41, and waste material trough plate 30 is horizontally fixedly arranged in winnowing box 25, and fan 28 is positioned at material storage dividing plate 26 and waste material trough plate Between...

Embodiment 3

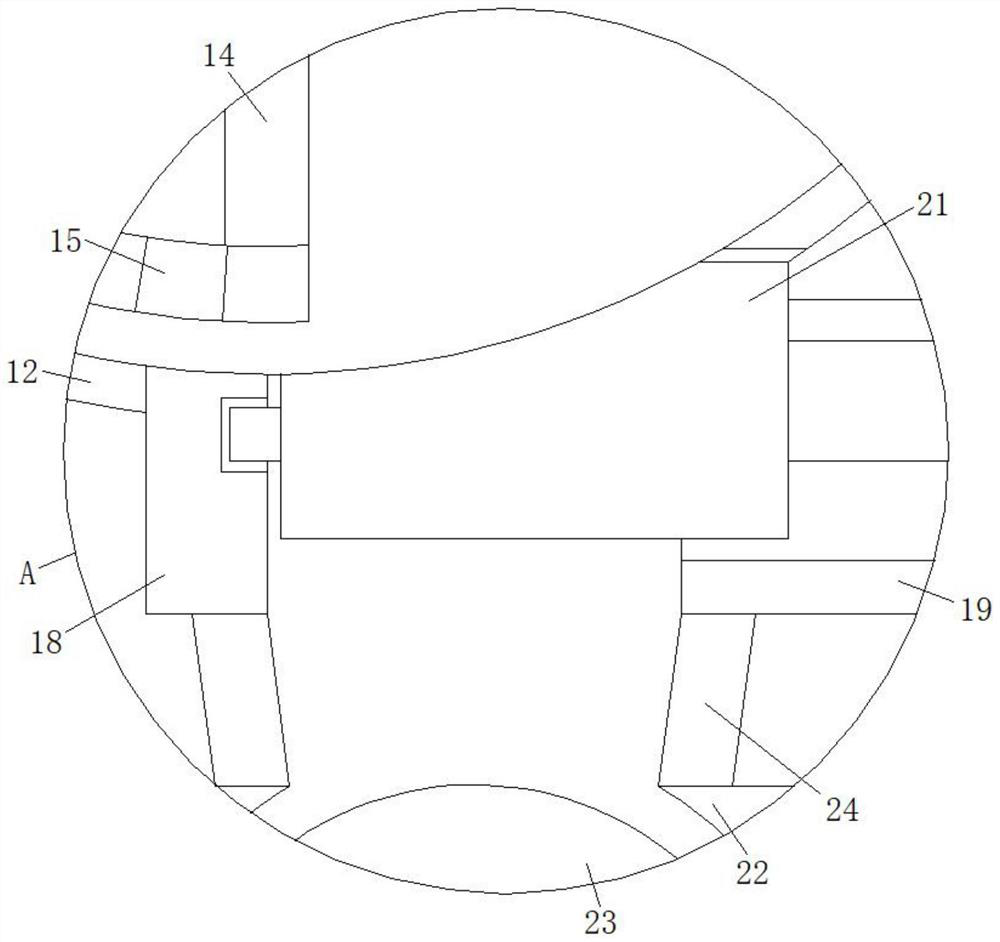

[0038] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1, and the more optimized part is that the cylinder body of the turning cylinder 12 is provided with a through hole one and a through hole two, the through hole one is located on one side of the material guide plate 11, and the through hole two Located on the bottom side of the turning cylinder 12, the bottom side of the turning cylinder 12 is fixedly connected with a vertical plate 18 and a mounting plate 19, the vertical plate 18 and the mounting plate 19 are respectively located on both sides of the through hole 2, and the cylinder 20 is horizontally installed on the mounting plate In the plate body of 19, the output rod transmission of cylinder 20 is connected with baffle plate 21, and one side of baffle plate 21 is in sliding contact with vertical plate 18.

[0039] In this embodiment, before the turning cylinder 12 performs humidity control adjustment, the material can be fed through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com