Wafer clamping device for single-wafer wet cleaning process cavity

A technology of wet cleaning and process chamber, which is applied in the direction of chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., to achieve the effect of reducing particle defects and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

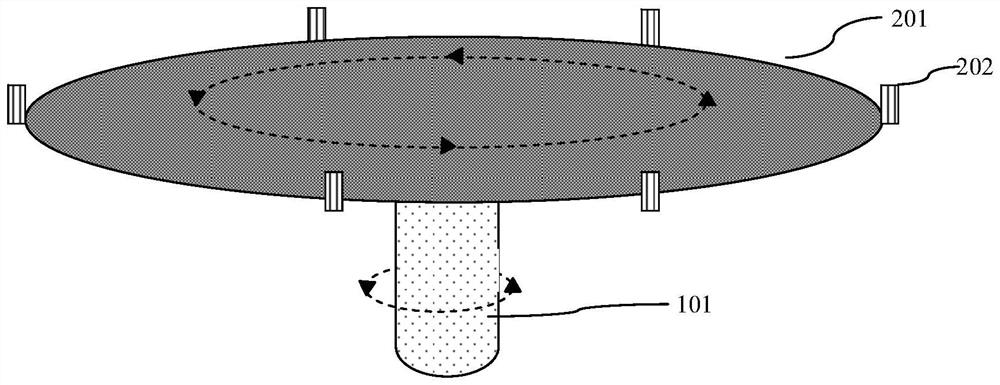

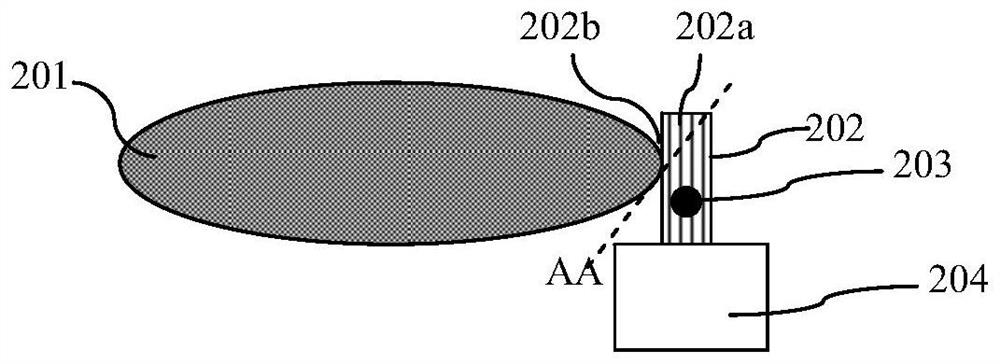

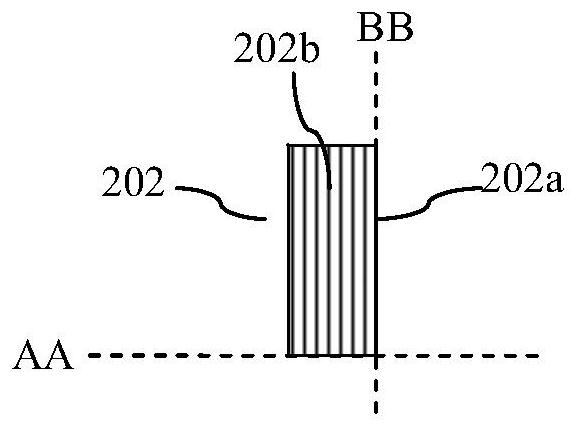

[0055] The wafer clamping device of the single-chip wet cleaning process chamber according to the first embodiment of the present invention:

[0056] Such as Figure 5A As shown, it is an enlarged schematic diagram of the structure of a thimble 302 when the wafer clamping device of the single-wafer wet cleaning process chamber in the first embodiment of the present invention is in a clamped state; Figure 5B yes Figure 5A A schematic structural view of the thimble 302 viewed toward the contact surface 302b of the thimble 302; Figure 6 As shown, it is an enlarged schematic diagram of the structure of a thimble 302 when the wafer clamping device of the single-chip wet cleaning process chamber in the first embodiment of the present invention is in the open state; the overall structure of the single-chip wet cleaning process chamber provided by the present invention Please also refer to figure 1 As shown; the wafer clamping device of the single-chip wet cleaning process chamb...

no. 2 example

[0078] The wafer clamping device of the single-chip wet cleaning process chamber according to the second embodiment of the present invention:

[0079] The difference between the wafer clamping device of the single-chip wet cleaning process chamber of the second embodiment of the present invention and the wafer clamping device of the single-chip wet cleaning process chamber of the first embodiment of the present invention is that the second embodiment of the present invention The wafer clamping device of the monolithic wet cleaning process chamber also has the following features:

[0080] Such as Figure 7A As shown, it is a perspective view of the size gradient structure of the thimble 302 of the wafer clamping device of the single-chip wet cleaning process chamber according to the second embodiment of the present invention; Figure 7B As shown, it is a front view along the contact surface 302b of the size gradient structure of the thimble 302 of the wafer clamping device of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com