Brake pad automatic drilling drill bit positioning and installation mechanism and installation method thereof

A technology for positioning and installation, brake pads, applied in positioning devices, drilling/drilling equipment, boring/drilling and other directions, which can solve the problems of heavy labor, wear of card grooves, poor positioning and installation accuracy of drill bits, etc. , to achieve the effect of reducing labor and ensuring firm installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

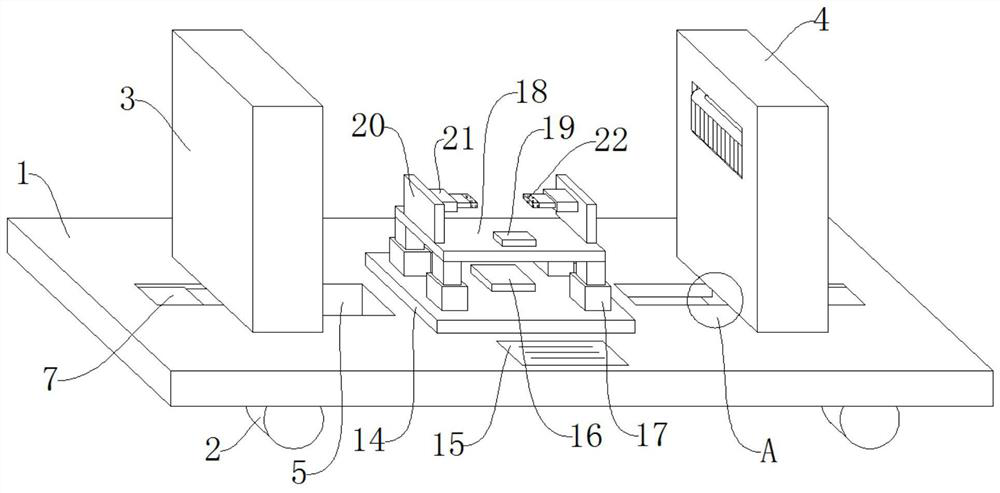

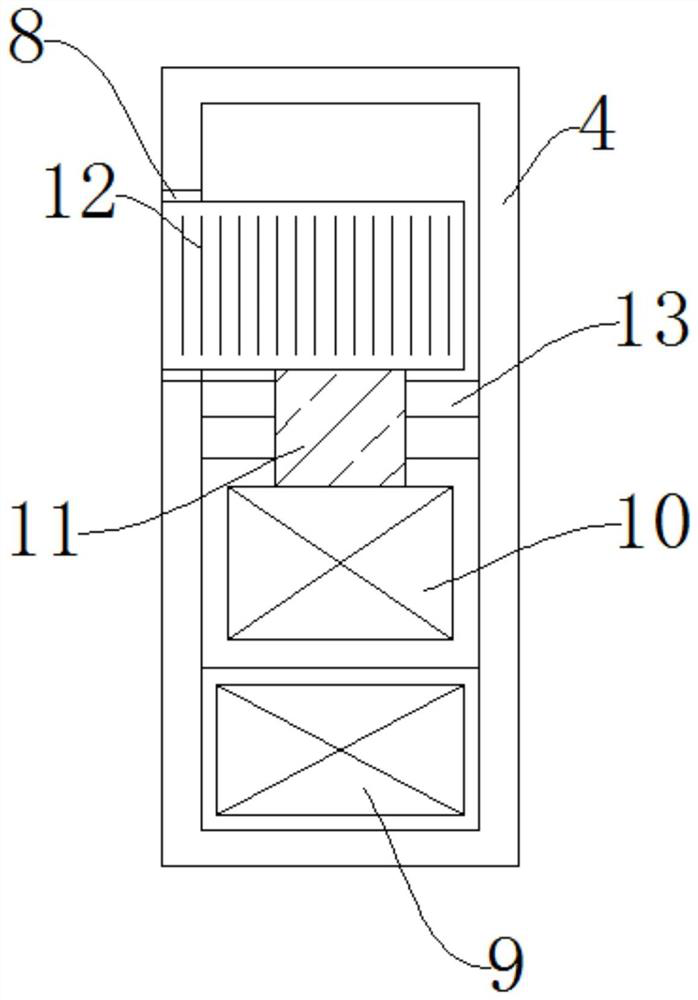

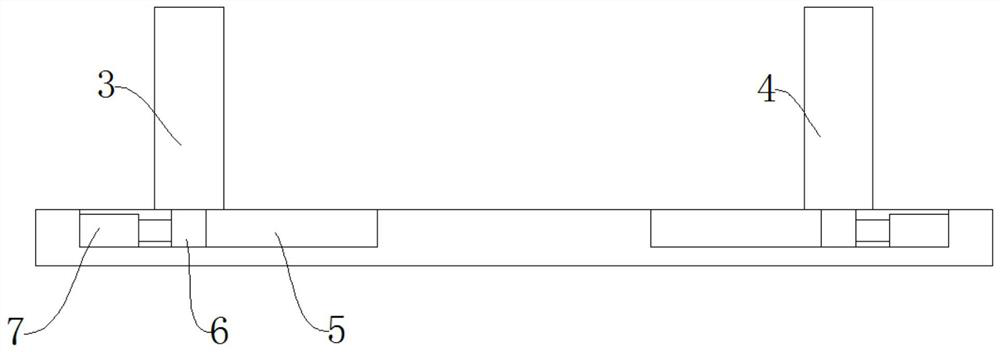

[0035] Such as Figure 1-Figure 4 As shown, a brake pad automatic drilling drill bit positioning and installation mechanism includes a base 1, a clamping column 3, a clamping column 2 4 and a level sensor 19, the four corners of the lower end of the base 1 are provided with rollers 2, and the base One side of the upper end of 1 is provided with the clamping column one 3, the other side of the upper end of the base 1 is provided with the clamping column two 4, the base 1 and the clamping column one 3 and the clamping column T-shaped chute 5 is respectively arranged at the junction of two 4, and T-shaped slide block 6 is all arranged at the junction of described clamping column one 3 and described clamping column two 4 and described T-shaped chute 5, and described T-shaped slide block 6 outsides are all provided with electric push rod one 7, are all provided with empty groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com