Machine tool chip rolling device for machining

A machining and chip rolling technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as waste of resources, reduce costs, increase storage space, and ensure waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

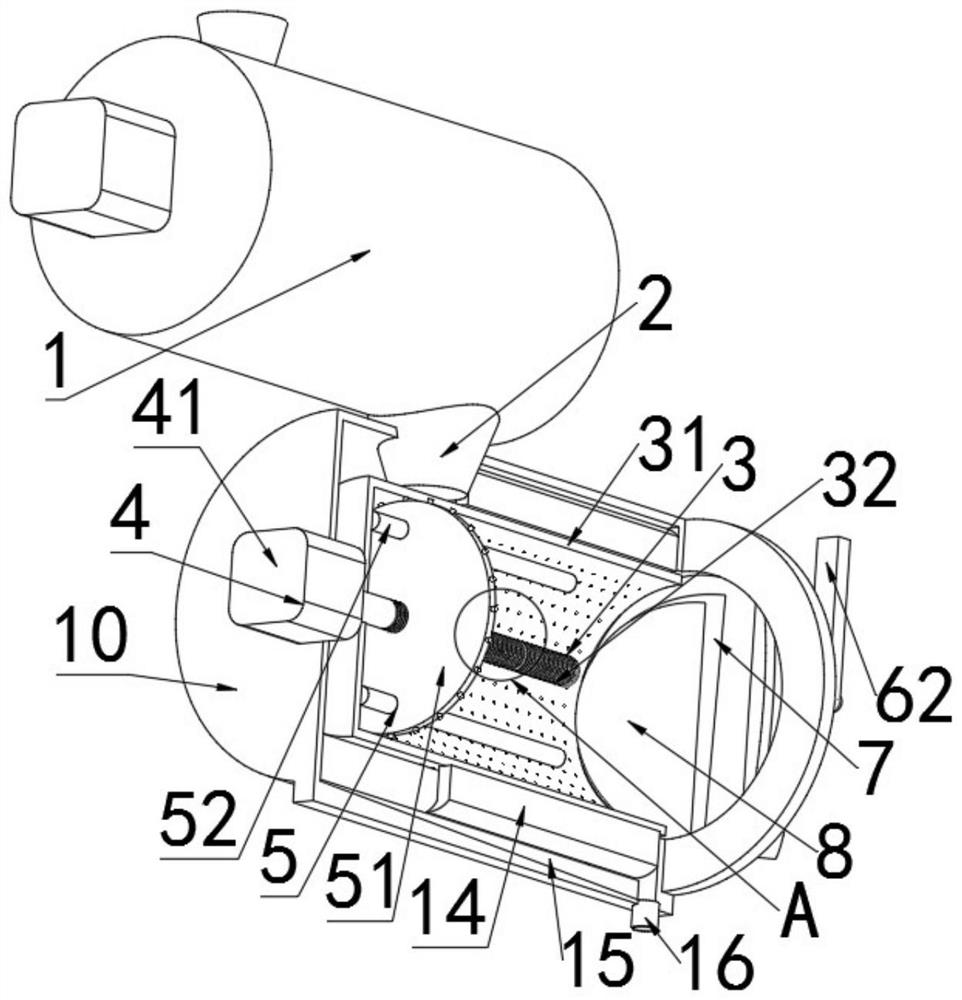

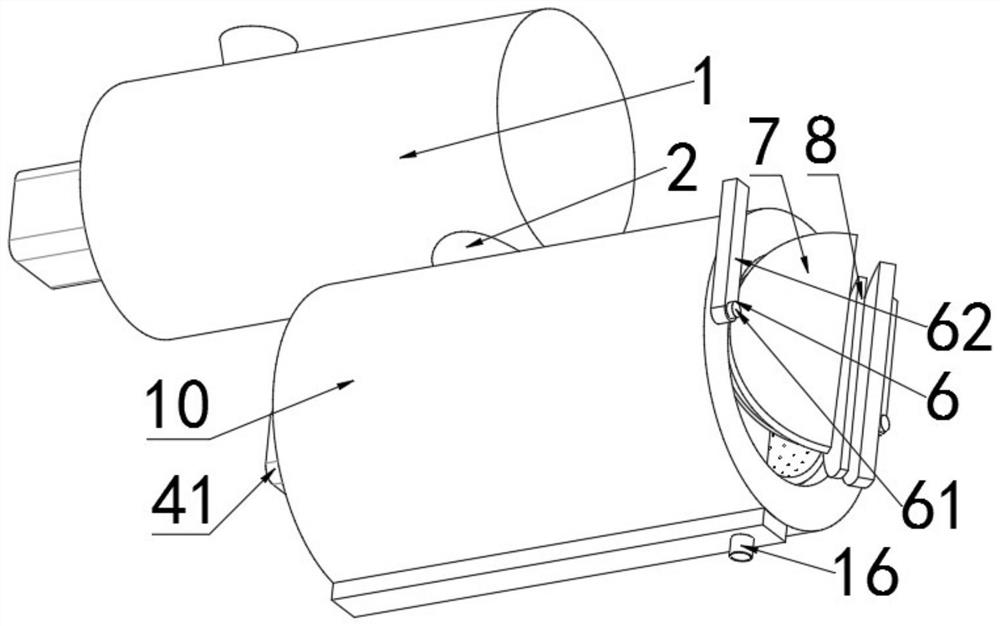

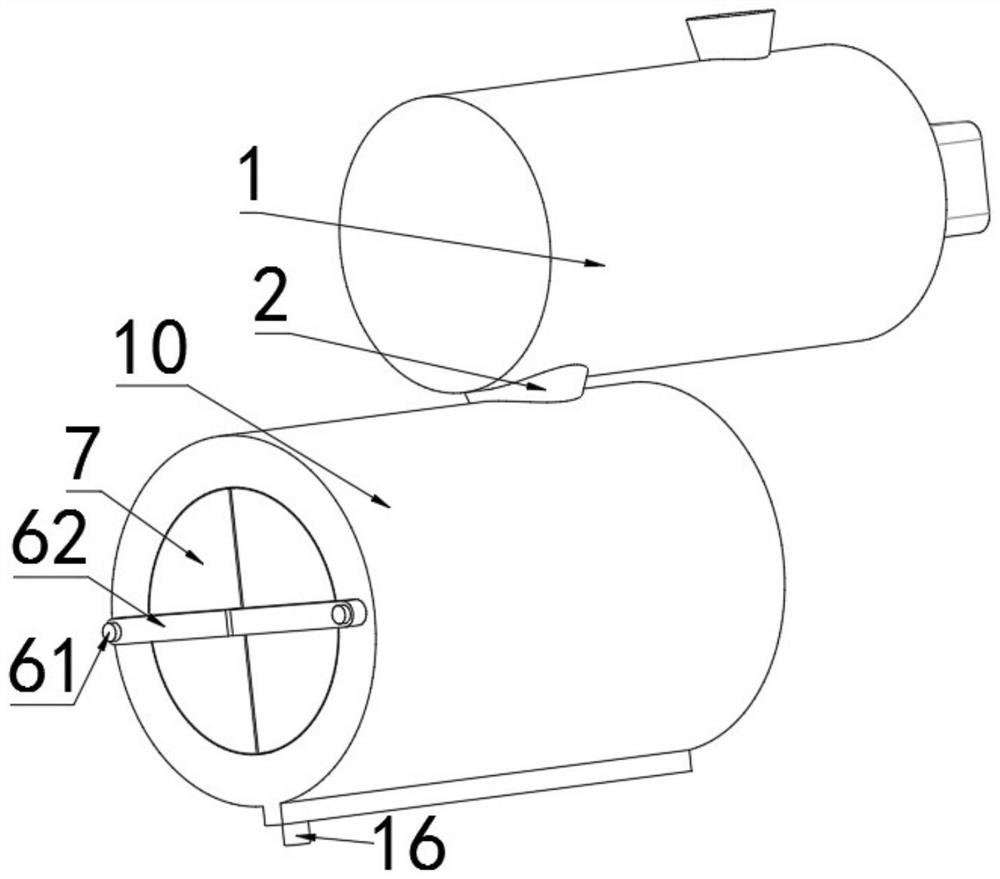

[0030] Refer Figure 1-5 , A machine tool for machining, including;

[0031] Vechnoid assembly 1, a crimping assembly 1 for transporting winding of seggers such as chipped parts produced on machine tools, and the disoelectric assembly 1 is mainly a crimping machine whose type includes a blade type, chain plate type, magnetic type As well as the spiral crimping machine, mainly used to transport the crumbs produced on the machine, and the working principle is the prior art, and will not be described later;

[0032] The cylindrical body 10 is opened in the cylinder 10, and the cylindrical 10 is used to collect and secondary processing, and the crimping assembly 1 is opened by the crimpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com