Rapid and high-efficiency oil removal air-floating filter tank

A technology of air flotation filter and flotation filter, which is applied in the direction of filtration treatment, flotation water/sewage treatment, grease/oily substance/suspton removal device, etc. It can solve the problem of incomplete backwashing of air flotation filter Unstable operation of the filter tank, failure to recycle and other problems, to achieve the effect of ensuring the quality and quantity of effluent water, good effluent water quality, and low construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

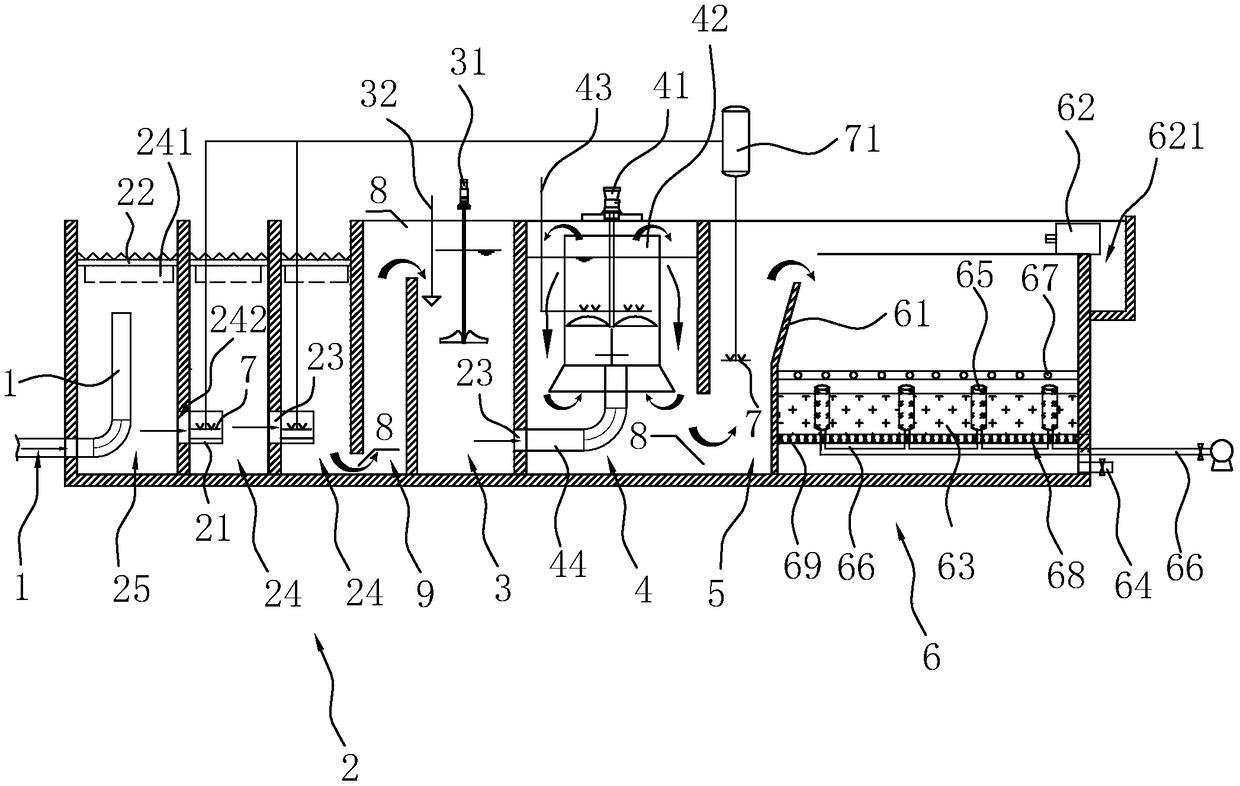

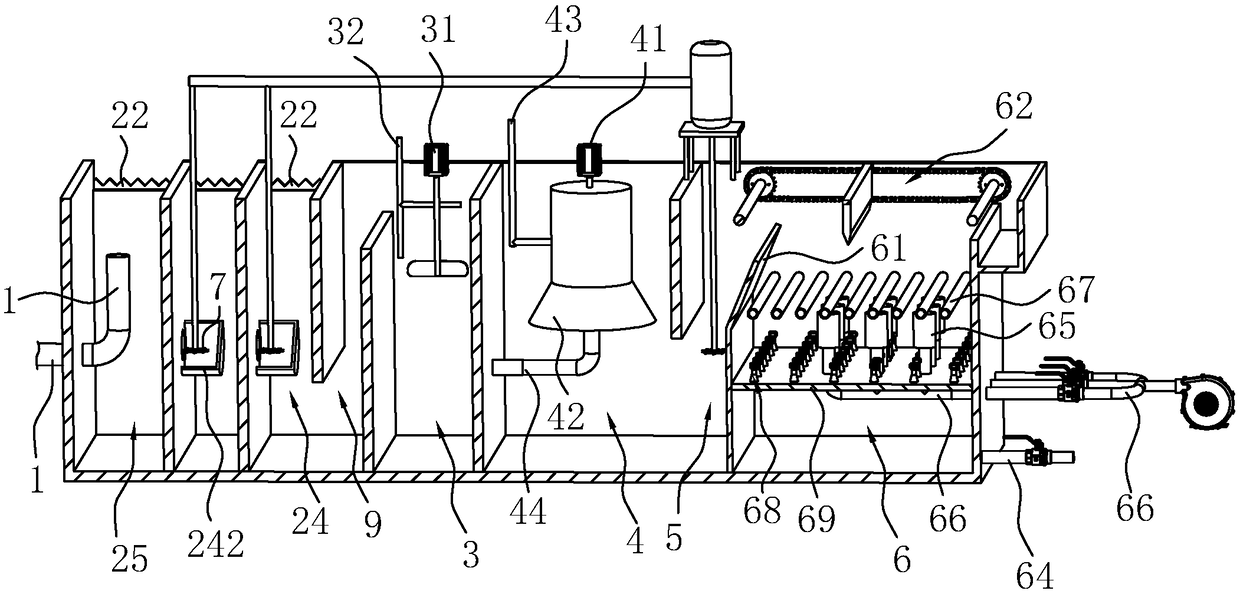

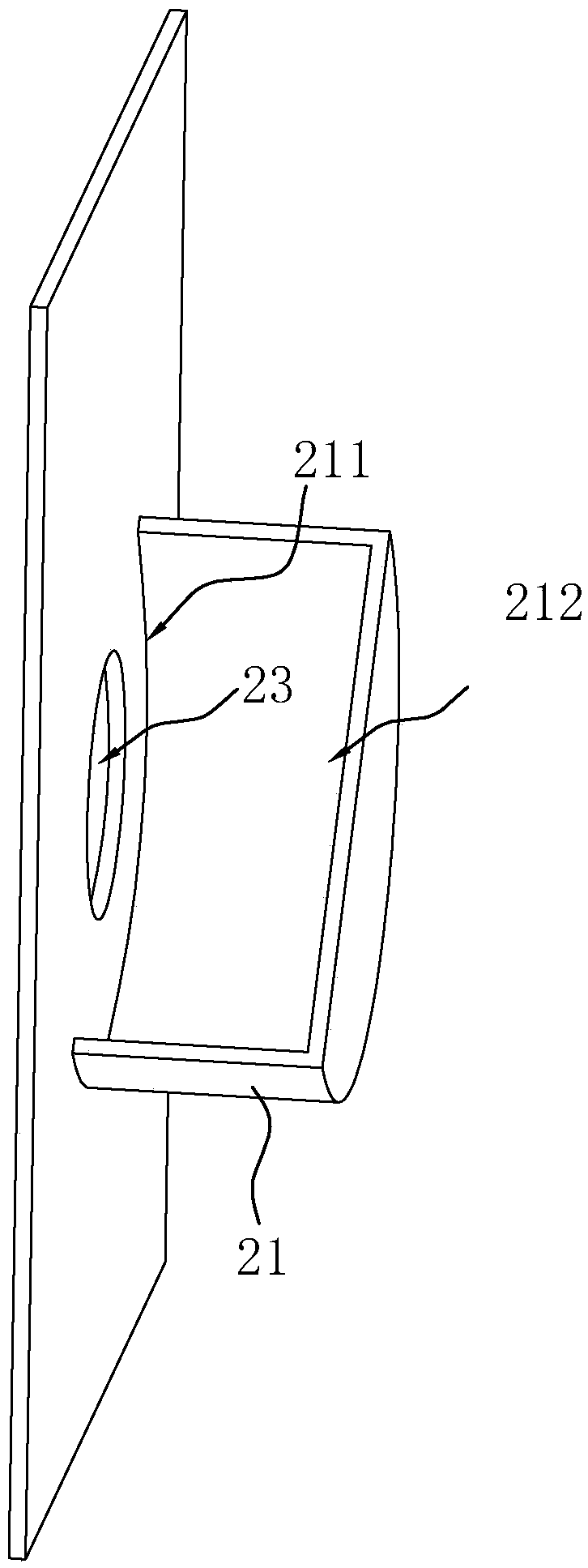

[0059] like figure 1 As shown, a high-speed degreasing device provided in this embodiment includes a water inlet chamber 25 and several air flotation chambers 24 arranged in sequence along the sewage flow direction, and the water inlet chamber 25 is connected to the water inlet pipe 1 on the side far away from the air flotation chamber 24 The water inlet pipe 1 passes through the wall of the water inlet chamber 25 away from the side of the air flotation chamber 24 and extends upward. The water inlet chamber 25 is communicated with the air flotation chamber 24 through a water passage 23, and the adjacent air flotation chambers 24 are also communicated through the water passage 23, and the water passage 23 is respectively arranged on the adjacent air flotation chamber 24 or Air flotation chamber 24 and water inlet chamber 25 are shared on the chamber wall. Each air flotation chamber 24 is provided with a dissolved air releaser 7 and a diversion tank 21, the dissolved air releas...

Embodiment 2

[0066] like figure 1 As shown, a fast and efficient degreasing device with a high-speed degreasing device provided in this embodiment includes a high-speed degreasing zone 2, a coagulation zone 3, a flocculation zone 4, and an air flotation zone arranged in sequence along the sewage flow direction 5 and filtering zone 6, the high-speed degreasing zone 2 comprises the high-speed degreasing device in embodiment 1, and a water passage 8 is passed between the high-speed degreasing zone 2 and the coagulation zone 3, the flocculation zone 4 and the air flotation zone 5 In communication, the water passage 8 can be arranged between the coagulation zone 3 and the flocculation zone 4 at the bottom of the shared wall in the adjacent area of the air flotation filter to communicate through the water passage 23 . The bottom of the filter area 6 is connected with an outlet pipe 64 for the water filtered by the air flotation to flow out. The high-speed degreasing zone 2 is used to efficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com