Follow-up device capable of driving semitrailer carriage to move longitudinally and semitrailer

A follow-up device and semi-trailer technology, which is applied in the direction of motor vehicles, tractor-trailer combination, transportation and packaging, etc., can solve the problems of semi-trailer turning blocked, etc., and achieve the goal of improving market competitiveness, reducing wind resistance and reducing transportation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] First of all, it needs to be explained that the "horizontal" mentioned in this technical solution refers to the width direction of the semi-trailer, and the "longitudinal" refers to the length direction of the semi-trailer.

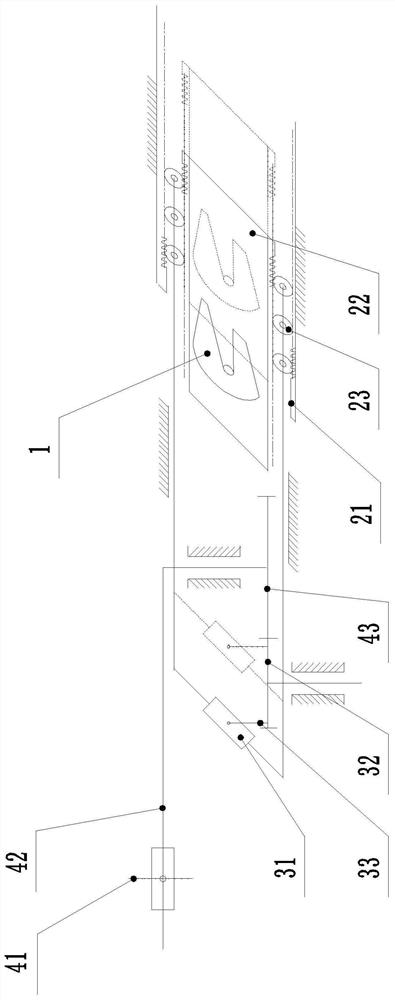

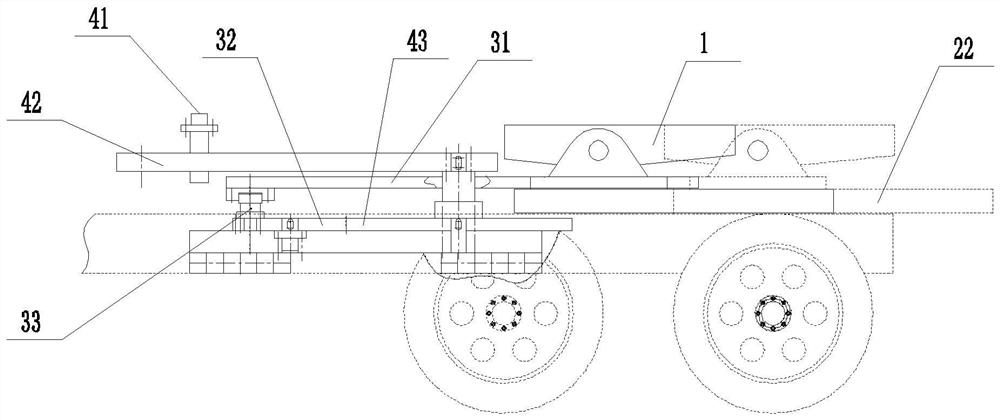

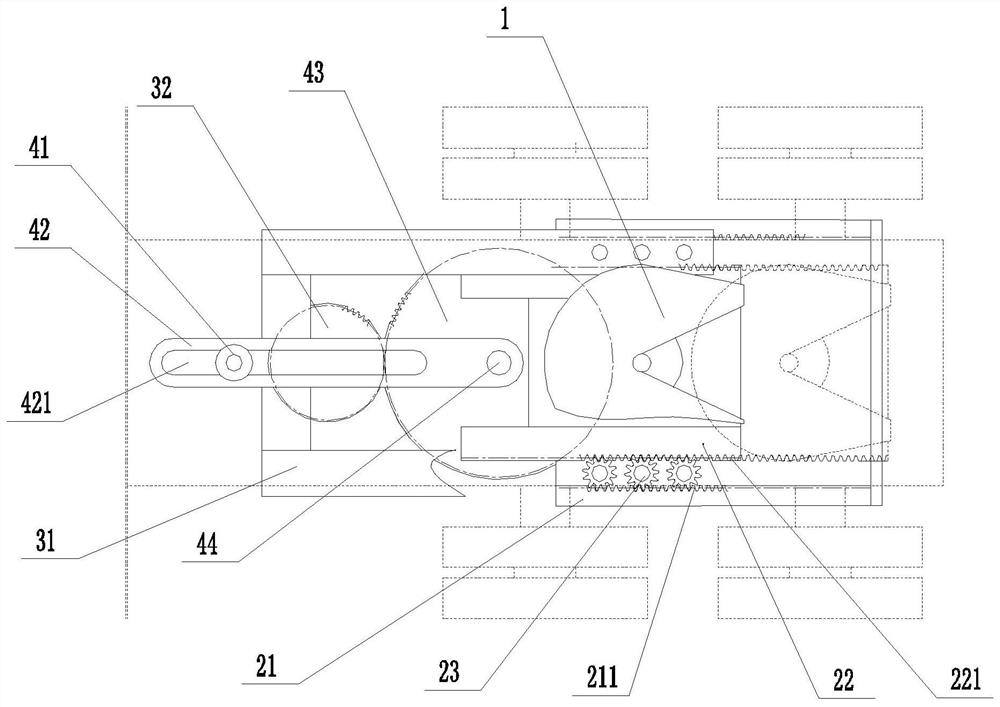

[0027] A follow-up device that can drive the longitudinal movement of the semi-trailer compartment, such as Figure 1 ~ Figure 3 with Figure 5 As shown, the follower is located between the tractor 100 and the semi-trailer compartment 200, and its bottom is fixed with the tractor 100, including the saddle 1, the slider crank mechanism, the generating mechanism and the driving mechanism.

[0028] The saddle 1 is located at the rear of the tractor 100 and is connected with the semi-trailer compartment 200 through the traction pin shaft. When the semi-trailer turns, the semi-trailer compartment 200 rotates along the traction pin shaft.

[0029] The generating mechanism is vertically arranged, and is a multiplication mechanism in which gears and racks...

Embodiment 2

[0038] Such as Figure 4 As shown, the specific structure of the driving mechanism can also be replaced by a servo motor 51 connected to the center of the crank part, and the servo motor 51 is connected to a control output end of a controller 52 .

[0039] Wherein, the controller 52 is a programmable logic controller based on PLC, and the control button of the controller 52 is arranged in the cab of the tractor, which is convenient for the driver to control the operation when turning. Specifically, when the semi-trailer enters a turning state, the driver presses the start button, and the controller 52 controls the operation of the servo motor 51 to start the operation of the slider crank mechanism, so that the longitudinal movement of the semi-trailer compartment 200 is achieved, so that out of the turning gap. When the relative rotation returns to the straight-ahead state after the turn is completed, the crank part rotates for a full circle, driving the multiplication slide ...

Embodiment 3

[0042] For embodiment one and embodiment two are further preferred, in order to ensure that when turning, the saddle 1 drives the semi-trailer compartment 200 to give enough distance backwards, that is, the gap between the tractor 100 and the semi-trailer compartment 200 can be made Minimal, to minimize the wind resistance during the driving of the semi-trailer. The distance between the connecting end of the crank part and the transverse groove 311 and the rotation center of the crank part is greater than or equal to 300-360 mm.

[0043] Moreover, at least three multiplication planetary gears 23 arranged longitudinally are connected to each longitudinal sliding block 312 . Drive strength can be guaranteed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com