Saturated PD type sliding mode control method and system of four-degree-of-freedom tower crane system

A control method and technology with degrees of freedom, applied in the directions of transportation and packaging, load hanging components, cranes, etc., can solve the problems such as the inability to guarantee the convergence of the sliding surface, the calculation difficulty of the equivalent control part, and the lack of depth, and achieve a simple structure. , easy to achieve, improve the effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

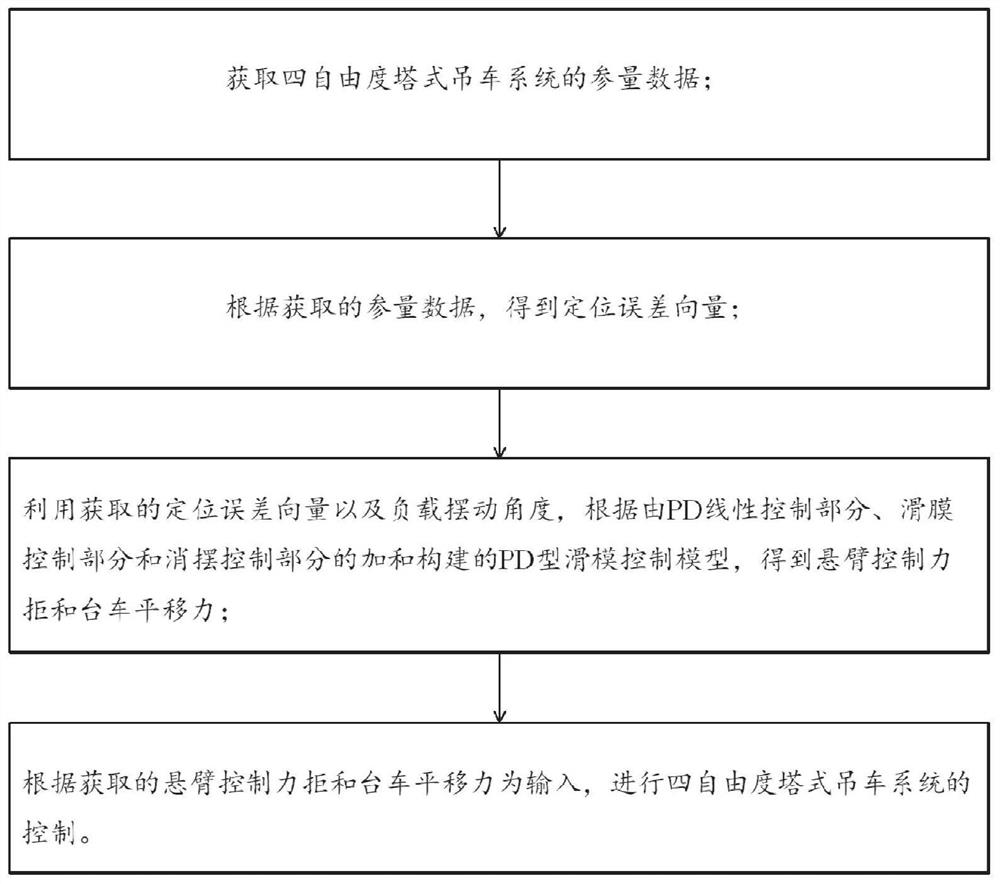

[0050] like figure 1 As shown, Embodiment 1 of the present disclosure provides a saturated PD sliding mode control method for a four-degree-of-freedom tower crane system, including the following process:

[0051] Obtain the parameter data of the four-degree-of-freedom tower crane system;

[0052] According to the acquired parameter data, a positioning error vector is obtained;

[0053] Using the obtained positioning error vector and load swing angle, according to the PD sliding mode control model constructed by the sum of the PD linear control part, the synovial film control part and the anti-swing control part, the cantilever control force and the trolley translation force are obtained;

[0054] According to the obtained cantilever control force and trolley translation force, the control of the four-degree-of-freedom tower crane system is carried out.

[0055] Specifically, include the following:

[0056] S1: Dynamic model of a four-degree-of-freedom tower crane system

...

Embodiment 2

[0260] Embodiment 2 of the present disclosure provides a saturated PD sliding mode control system for a four-degree-of-freedom tower crane system, including:

[0261] The data acquisition module is configured to: acquire parameter data of the four-degree-of-freedom tower crane system;

[0262] The error vector acquisition module is configured to: obtain a positioning error vector according to the acquired parameter data;

[0263] The control variable calculation module is configured to: use the acquired positioning error vector and load swing angle, and obtain the cantilever control force sum trolley translational force;

[0264]The control module is configured to: control the four-degree-of-freedom tower crane system according to the obtained cantilever control force and the trolley translation force.

[0265] The working method of the system is the same as the saturated PD sliding mode control method of the four-degree-of-freedom tower crane system provided in Embodiment 1...

Embodiment 3

[0267] Embodiment 3 of the present disclosure provides a computer-readable storage medium on which a program is stored. When the program is executed by a processor, the saturated PD-type slide of the four-degree-of-freedom tower crane system described in Embodiment 1 of the present disclosure is realized. Steps in the modulo control method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com