Magnesium oxide and zinc oxide suspension fertilizer and preparation method thereof

A technology of zinc oxide and magnesium oxide, which is applied in the direction of magnesium fertilizer, organic fertilizer, inorganic fertilizer, etc., can solve the problems of low concentration, high fineness requirements of magnesium oxide and calcium oxide, poor stability, etc., and achieve high concentration and good promotion and application prospects , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

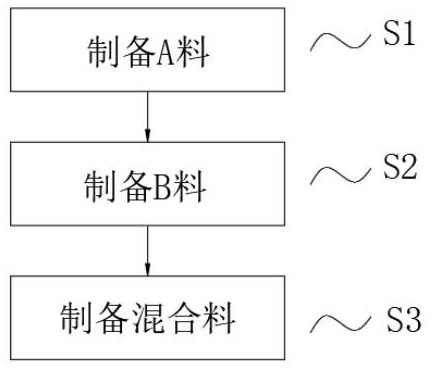

Method used

Image

Examples

Embodiment 1

[0037] The invention provides a technical solution: a suspension fertilizer of magnesium oxide and zinc oxide, material A is prepared from the following components by mass: 29.0 parts of water, 38.6 parts of urea nitramine solution, 4.2 parts of polyol, and 1.0 part of dispersant , 2.3 parts of wetting agent, 3.6 parts of antifreeze, 0.2 parts of defoamer, 4.0 parts of thickener, 8.6 parts of high molecular polymer, 1.2 parts of humic acid and 6.3 parts of diatomaceous earth;

[0038] The material B is prepared from the following components by mass: 50.0 parts of magnesium oxide, 1.0 parts of dispersant, 29.0 parts of water, 4.2 parts of polyol, 2.3 parts of wetting agent, 0.2 parts of defoaming agent, 1.8 parts of salad oil, 0.6 parts of rhamnolipid, 8.6 parts of high molecular polymer.

[0039]In this embodiment, the polyol is polyethylene glycol, the dispersant is polycarboxylate, the wetting agent is alkyl glycoside, the defoamer is silicone defoamer, and the antifreeze is...

Embodiment 2

[0050] The invention provides a technical solution: a suspension fertilizer of magnesium oxide and zinc oxide, material A is prepared from the following components by mass: 31.0 parts of water, 76.9 parts of urea nitramine solution, 6.2 parts of polyol, and 6.0 parts of dispersant , 4.7 parts of wetting agent, 6.6 parts of antifreeze, 0.4 parts of defoamer, 5.0 parts of thickener, 11.4 parts of high molecular polymer, 4.7 parts of humic acid and 10.5 parts of diatomaceous earth;

[0051] The material B is prepared from the following components by mass: 70.0 parts of zinc oxide, 6.0 parts of dispersant, 31.0 parts of water, 4.7 parts of wetting agent, 6.6 parts of antifreeze, 0.4 parts of defoamer, 5.6 parts of salad oil, 1.5 parts of rhamnolipid, 1.4 parts of high molecular polymer.

[0052] In this embodiment, the polyol is polyethylene glycol, the dispersant is polycarboxylate, the wetting agent is alkyl glycoside, the defoamer is silicone defoamer, and the antifreeze is gly...

Embodiment 3

[0063] The invention provides a technical solution: a suspension fertilizer of magnesium oxide and zinc oxide, material A is prepared from the following components by mass: 30.0 parts of water, 50.7 parts of urea nitramine solution, 5.0 parts of polyol, and 3.0 parts of dispersant , 2.0 parts of wetting agent, 5.2 parts of antifreeze, 0.3 parts of defoamer, 4.5 parts of thickener, 10.2 parts of high molecular polymer, 3.1 parts of humic acid and 8.5 parts of diatomaceous earth;

[0064] The material B is prepared from the following components by mass: 60.0 parts of magnesium oxide and zinc oxide mixture, 3.0 parts of dispersant, 30.0 parts of water, 5.0 parts of polyol, 2.0 parts of wetting agent, 3.0 parts of salad oil, cascara 1.0 parts of glycolipid, 4.5 parts of thickener, 10.2 parts of high molecular polymer.

[0065] In this embodiment, the polyol is polyethylene glycol, the dispersant is polycarboxylate, the wetting agent is alkyl glycoside, the defoamer is silicone def...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap