Connecting structure of inclined strut prefabricated concrete pipe pile columns and hollow floor or flat slab

A technology of prefabricated concrete and hollow floors, which is applied in the directions of columns, slabs, pier columns, etc., can solve the problems of high cost, high installation technology and precision requirements, and reduced seismic performance, and achieve a high degree of standardization and mass production , the effect of improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

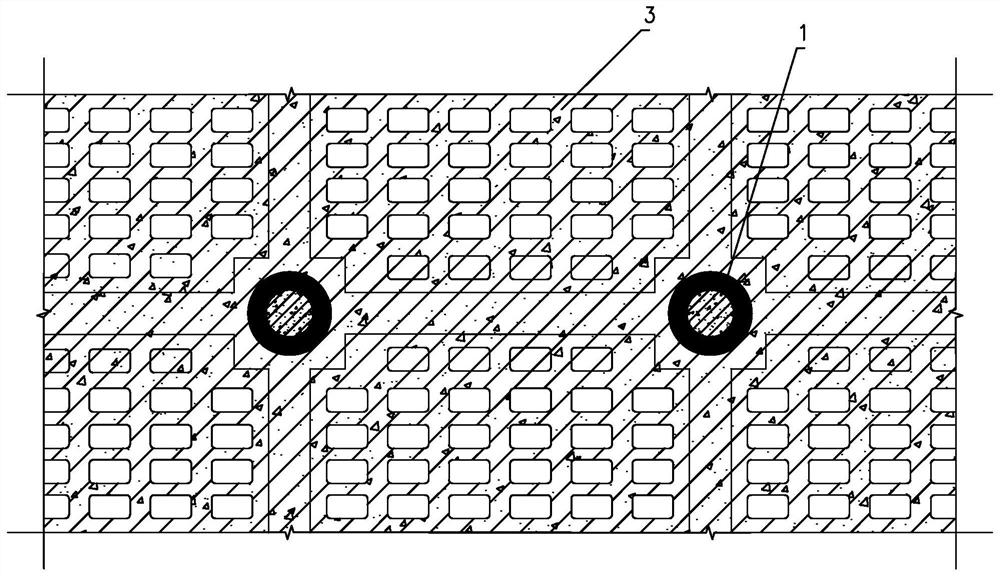

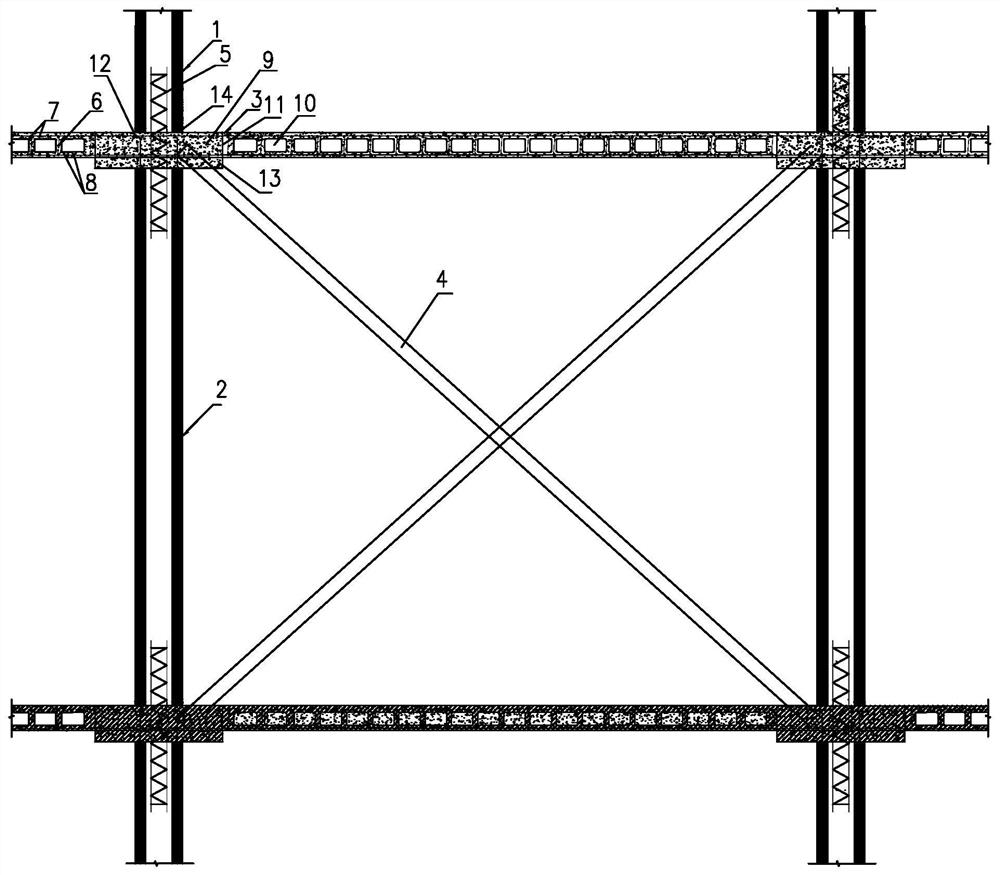

[0038] Such as figure 1 and 2 Shown, it is a kind of connection structure between the prefabricated concrete pipe pile column and the hollow floor or the beamless floor of the present invention, which includes the upper floor prefabricated concrete pipe pile column 1, the lower floor prefabricated concrete pipe pile column 2, the diagonal brace 4 and The hollow floor 3, the precast concrete pipe pile 1 on the upper floor and the precast concrete pipe pile 2 on the lower floor are all formed by inserting the connecting steel bar 5 into the core hole of the precast concrete pipe pile and pouring in-situ concrete. The upper precast concrete pipe pile 1 and the The lower prefabricated concrete pipe pile 2 can use prestressed or non-prestressed steel bars or mixed prestressed and non-prestressed PHC / PC / PRCI / PRCII hollow pipe piles or other pipe piles mixed with prestressed steel bars and ordinary steel bars , You can also use any other strength, type of pipe pile, the cross-sectio...

Embodiment 2

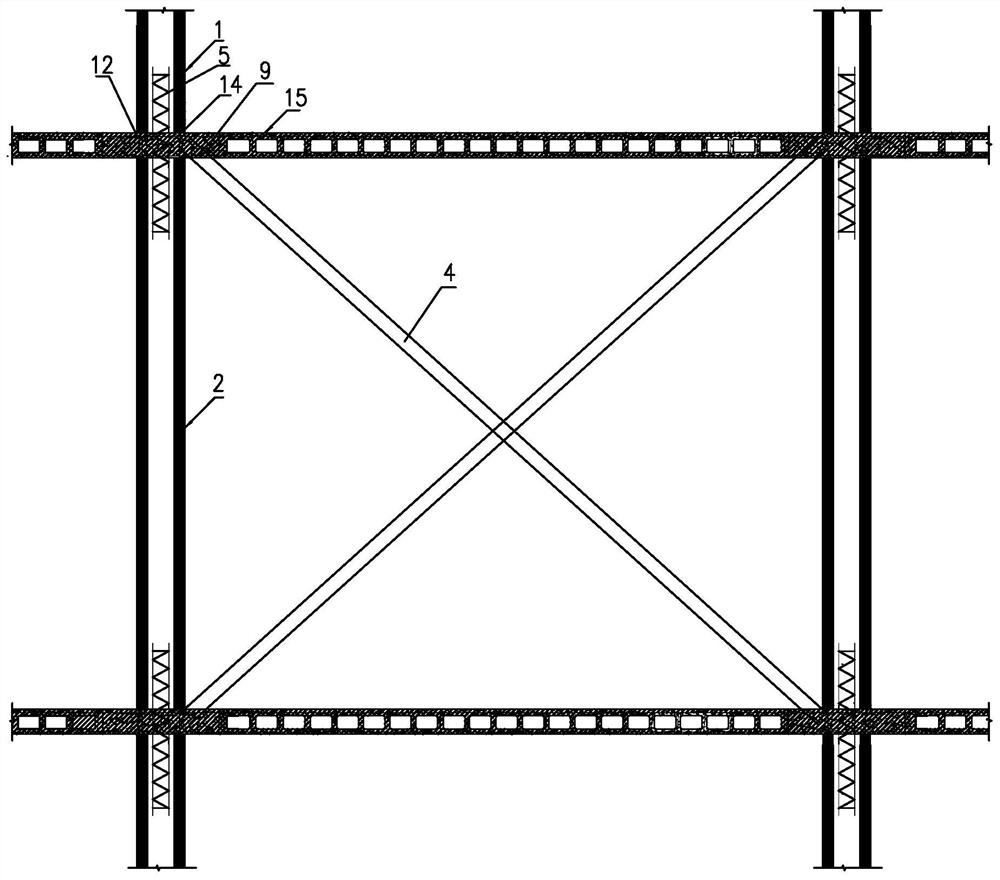

[0054] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the floor is a beamless floor 15, and no supporting member is set on the top of the precast concrete pipe pile column 2 on the lower floor, and no beams are provided in it, and the floor The load is directly transmitted to the foundation by the slab through the column. This structure is simple in force transmission and increases the net height of the floor.

Embodiment 3

[0056] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the supporting member set on the top of the lower precast concrete pipe pile 2 is a column cap 16, and for heavy loads, a flat Supporting plate, in order to reduce the bending moment value in the floor and bear the punching force, increase the rigidity of the floor, so that the load of the plate is transmitted to the column relatively smoothly. For light loads, there is no need to set a flat support plate above the column cap. In the slab-column joint area 9, the dimensioning should accommodate the 45° punching failure cone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com