Integrated connecting rod horizontally-opposed double-piston oil-free air compressor

An air compressor, horizontally opposed technology, applied in the field of air compressors, can solve the problems of wear of piston rings, increased vibration intensity of air compressors, incomplete strokes, etc., to ensure safe and stable operation, avoid changes in compression, Avoid the effects of accelerated wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

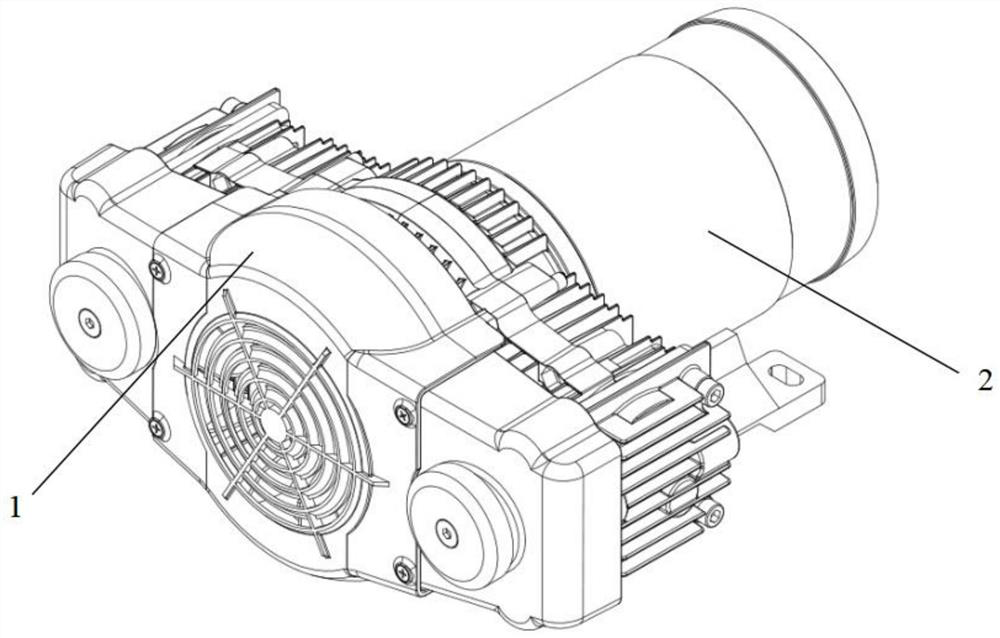

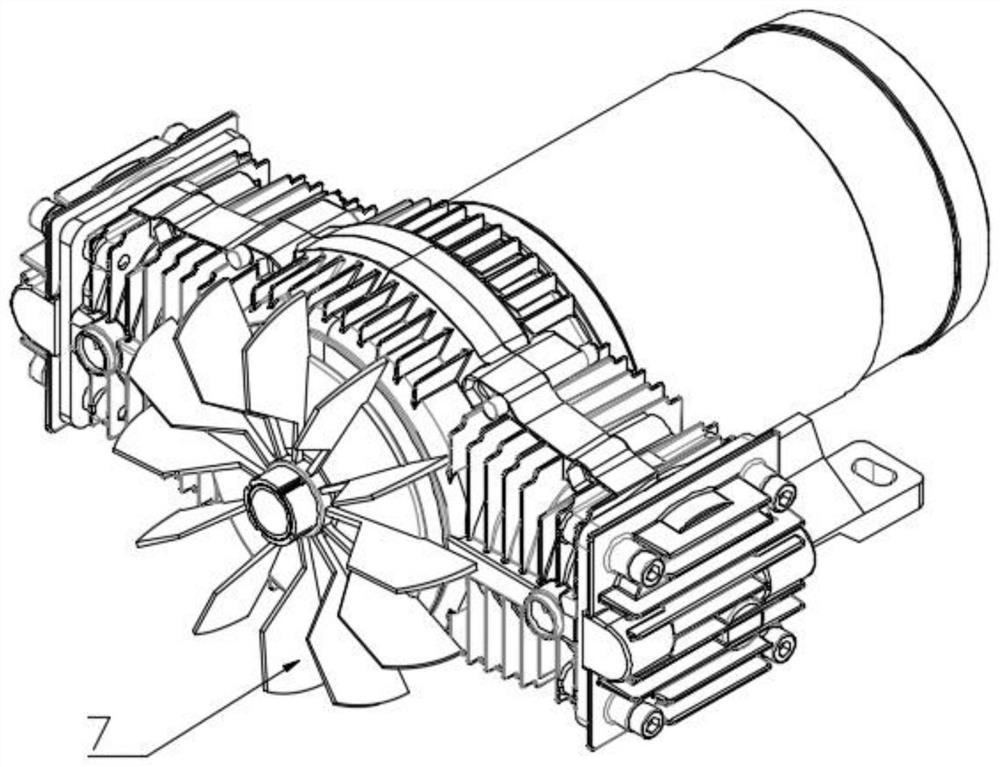

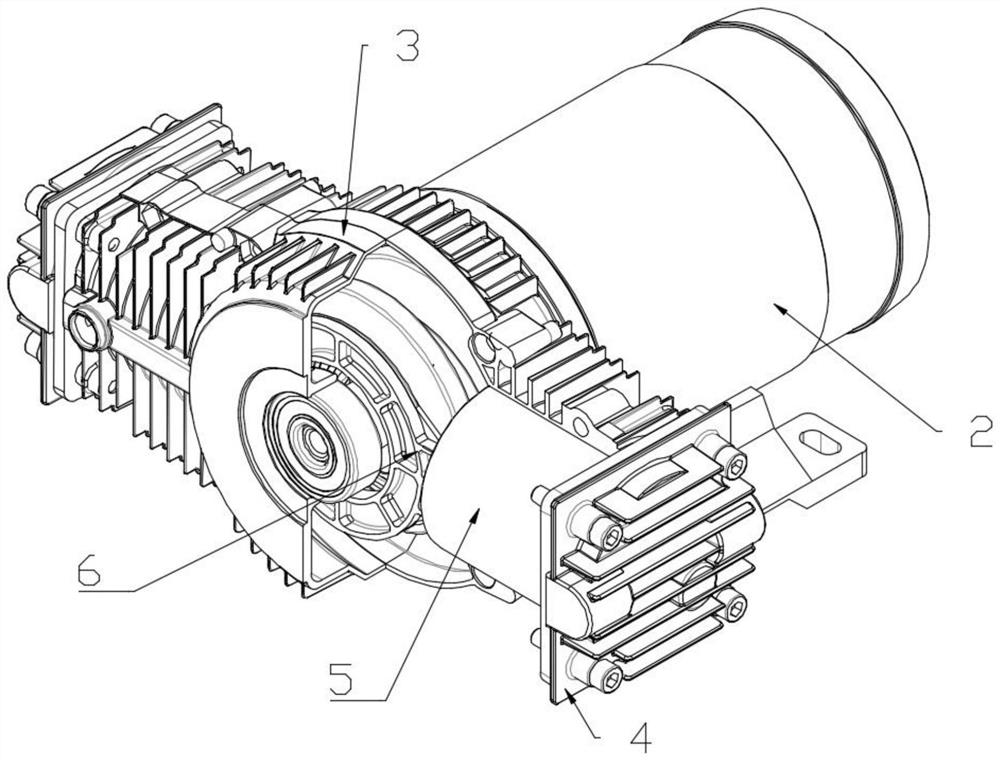

[0035] like Figure 1-14 As shown, an embodiment of the integrated connecting rod horizontally opposed double-piston oil-free air compressor provided by the present invention includes a crankcase 3, a drive motor 2, and a flange on the crankcase 3 and the drive motor 2. Fixedly connected, it also includes a crank linkage mechanism, which is located in the crankcase 3, and the crank linkage mechanism includes an integrated connecting rod 6 and an eccentric transmission linkage assembly. Pistons are respectively installed at the ends, and the integrated connecting rod 6 is rotationally connected with the eccentric transmission connecting rod assembly, and the eccentric transmission connecting rod assembly is connected with the main shaft 11 of the driving motor 2, so as to convert the rotational motion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com