Quick-release type safety control mechanism for valve body

A safety-controlled, quick-release technology, applied in the valve shell structure, the valve's device for absorbing fluid energy, and the valve lifter. The problem of high replacement cost can achieve the effect of improving the degree of integration, compact structure and reducing maintenance difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

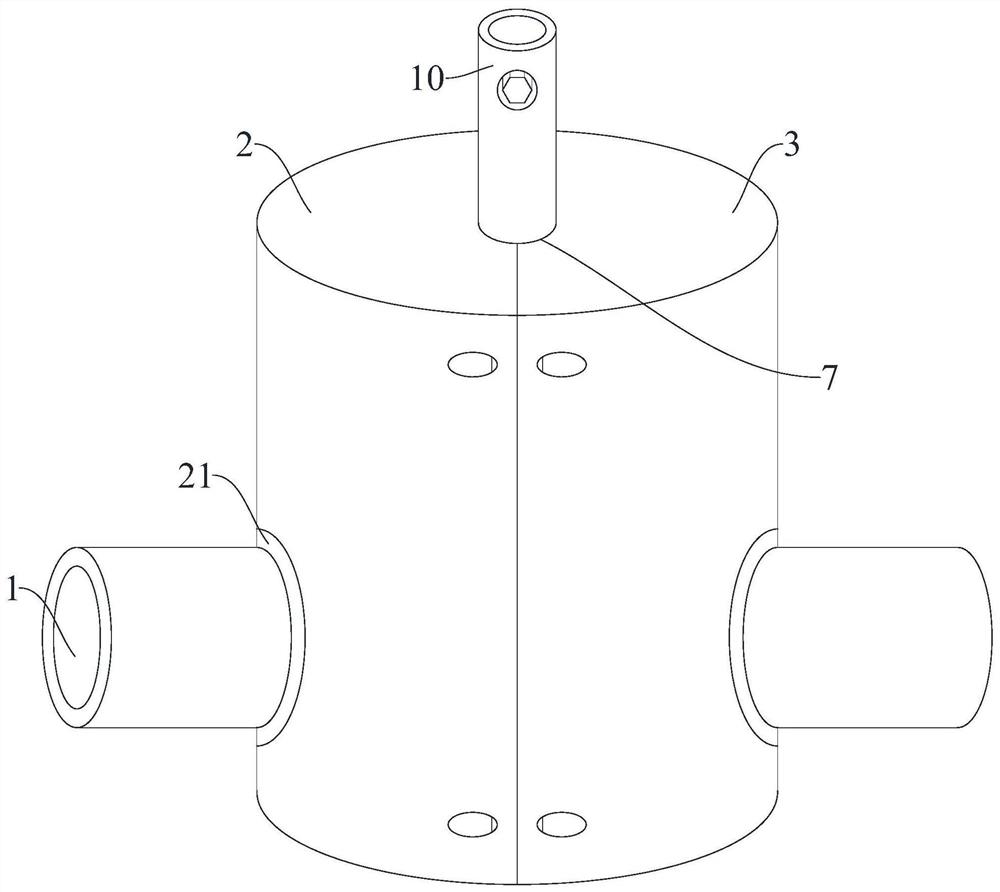

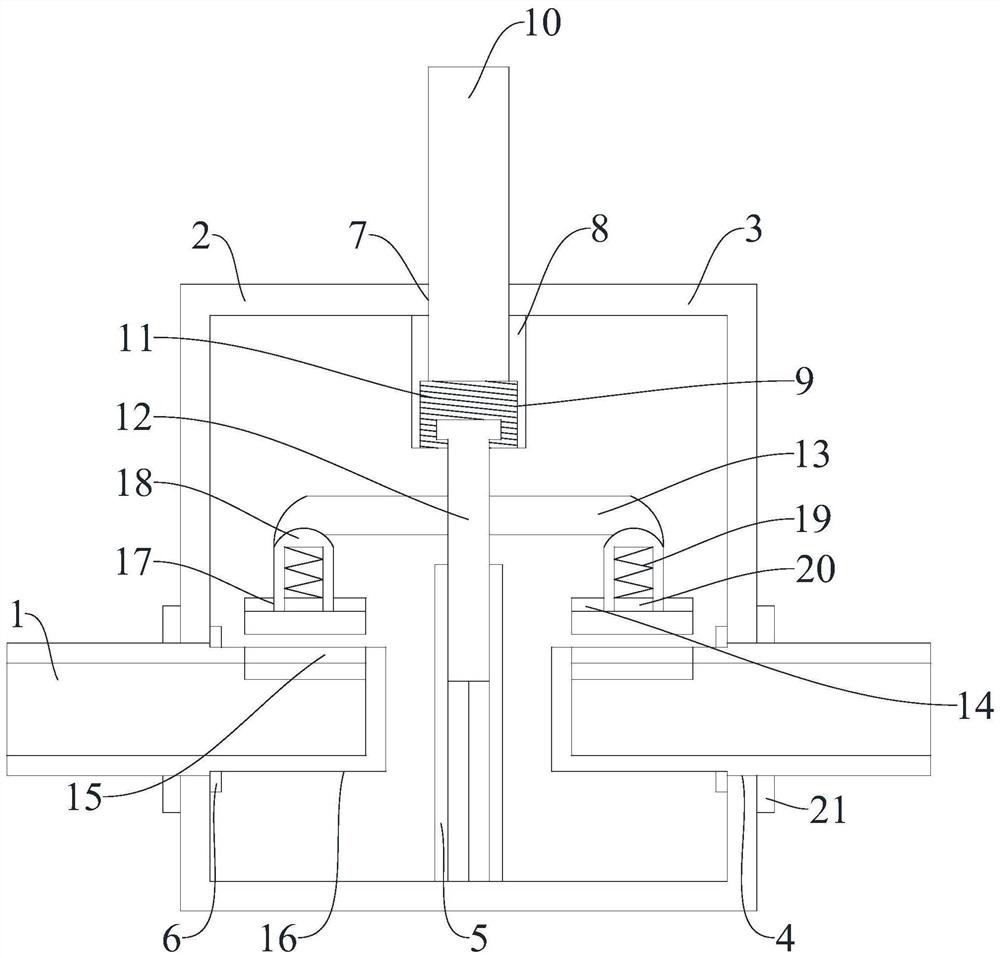

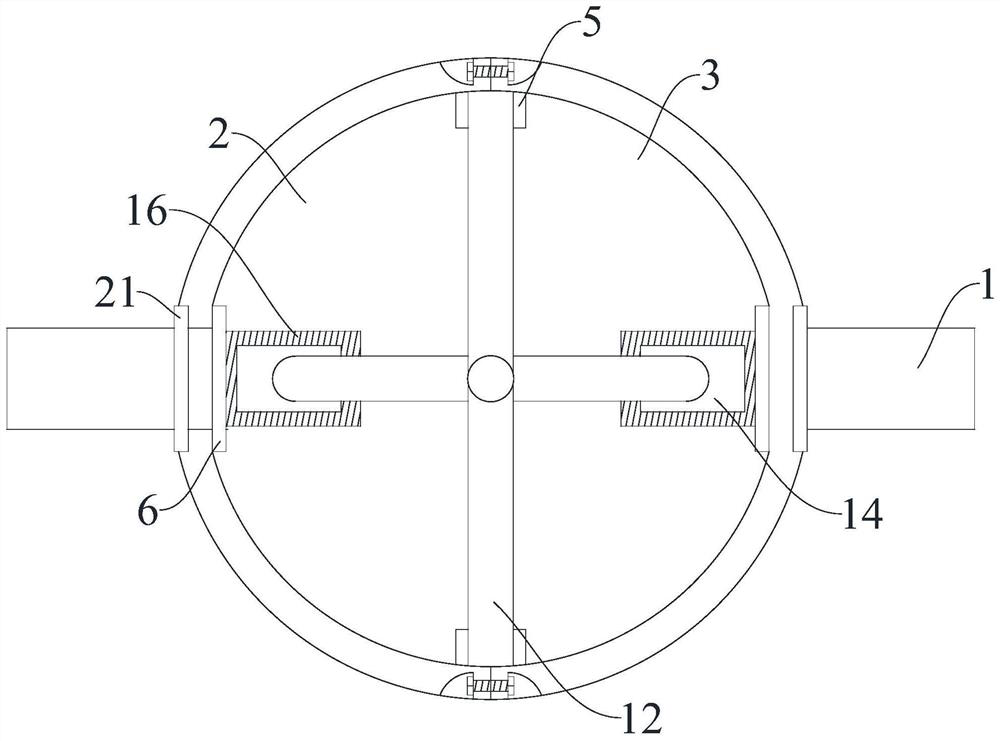

[0027] Example: People first insert the lateral conveying pipe 1 into the lateral assembly hole 4, and then fix it with the inner thread fastening sleeve 6, and then insert the vertical guide plate 12 into the inner guide frame 5, and screw the left The housing 2 and the right housing 3 are fixedly connected, and the external control rod 10 is assembled by using the longitudinal guide tube, and the inner arc-shaped thread adjusting groove 9 is threadedly engaged with the external thread adjusting sleeve 11 .

[0028] Further, in order to cooperate with the installation and adjustment of the external control mechanism, the middle position of the inner top surface of the left housing 2 and the middle position of the inner top surface of the right housing 3 are provided with arc adjustment grooves 7, and the inner top surface of the left housing 2 is provided with an arc adjustment groove 7. The middle position and the inner top surface of the right housing 3 are located in the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com