Deep blasting failure area shape prediction method based on ADABOOST integration algorithm

A prediction method and damage zone technology, applied in CAD numerical modeling, special data processing applications, instruments, etc., can solve the problems of low cost performance and large development costs, and achieve low development costs, good adaptability, and good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

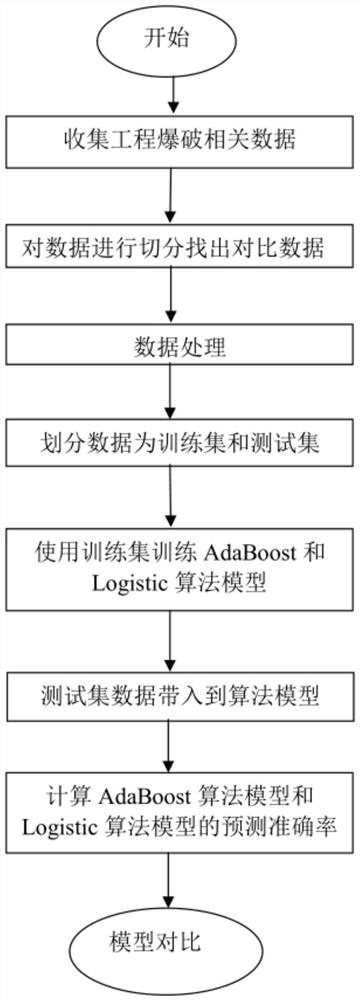

[0037] Embodiment 1: a kind of deep blasting damage zone shape prediction method based on ADABOOST integrated algorithm comprises the steps:

[0038] Step 1: Collect the recorded data of the simulated real scene in the laboratory, obtain the original data, conduct correlation analysis on the original data, find out the main influencing factors affecting the shape change of the blasting damage zone, and obtain the main factors;

[0039] Step 2: Segment the original data, find the data with comparative feasibility, and obtain the segmented data;

[0040] Step 3: Perform missing value processing, outlier detection, and normalization processing on the segmented data, and then process the data again;

[0041] Step 4: Segment the reprocessed data to obtain a training data set and a testing data set;

[0042] Step 5: Use the training data set to train the AdaBoost integrated algorithm model and the Logistic algorithm model to obtain the trained AdaBoost integrated algorithm model an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com