Catalytic cracking reaction process modeling method and device

A catalytic cracking and modeling method technology, applied in the field of catalytic cracking reaction process modeling methods and devices, can solve the problems of complex reaction process, reflecting the influence of raw material properties change product distribution and properties, poor adaptability, etc., to achieve model solution easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] The present embodiment proposes a catalytic cracking reaction process modeling method:

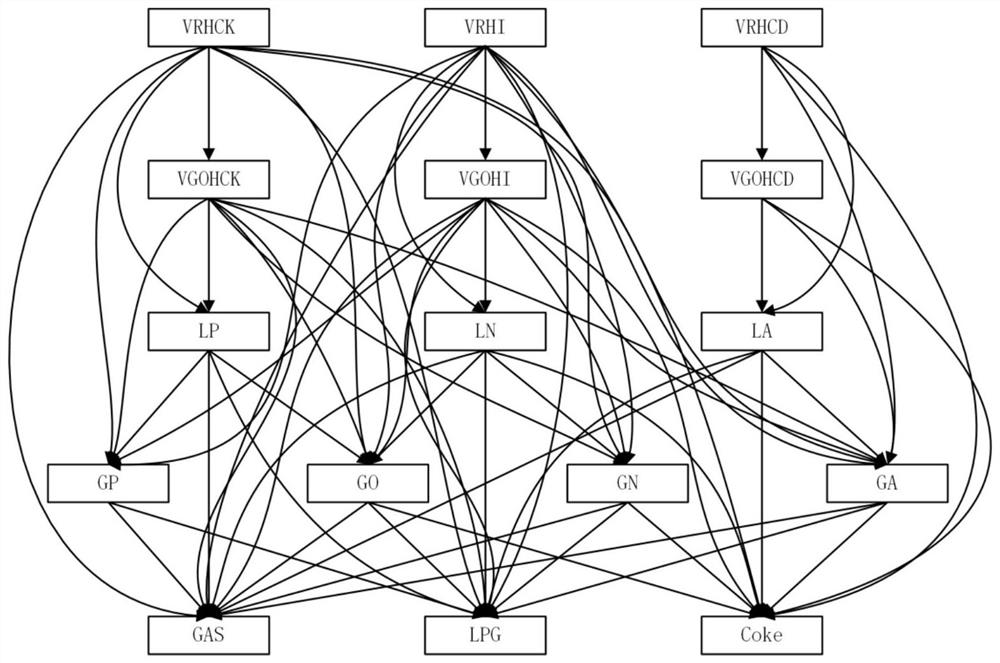

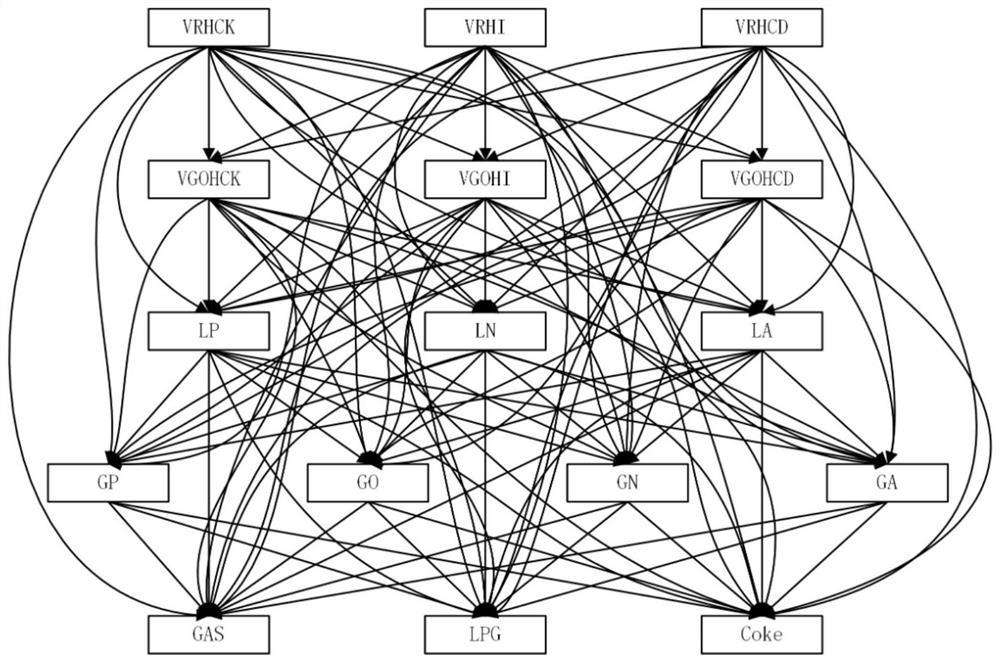

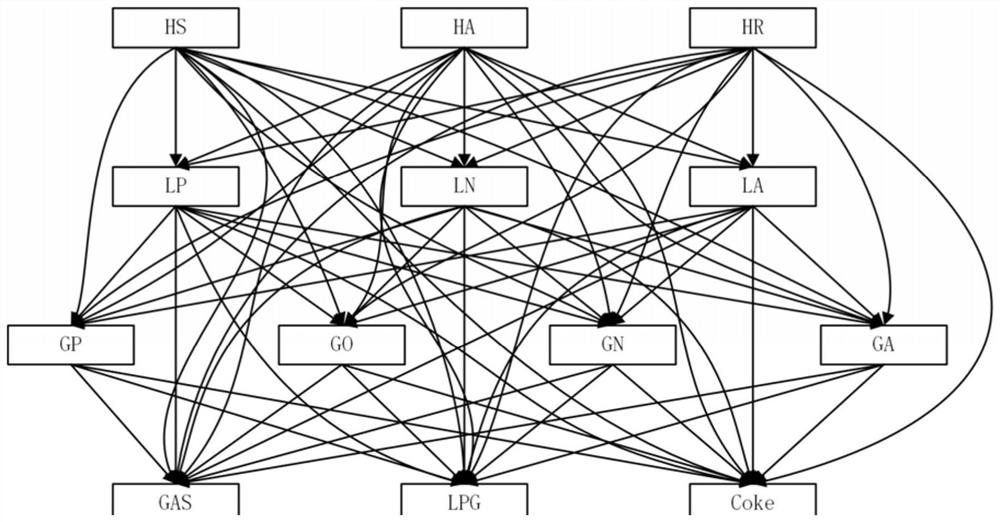

[0124] Step 1: Divide the raw materials and products into vacuum residue easily cracked lumped (VRHCK), vacuum residue intermediate lumped (VRHI), vacuum residue easily condensed lumped (VRHCD), distillate easily cracked lumped Total (VGOHCK), Lumped Distillate Intermediate (VGOHI), Lumped Distillate Easy Condensation (VGOHCD), Lumped Dry Gas (GAS), Lumped Liquefied Gas (LPG), Lumped Gasoline Paraffin (GP), Gasoline Lumped Olefins (GO), Lumped Gasoline Naphthenes (GN), Lumped Gasoline Aromatics (GA), Lumped Diesel Paraffins (LP), Lumped Diesel Naphthenes (LN), Lumped Diesel Aromatics (LA) and Coke lumps (Coke, CK for short) have a total of 16 lumps.

[0125] Step 2: According to the divided lumped and catalytic cracking reaction mechanism, establish a catalytic cracking reaction network, such as figure 1 shown, including 64 reactions.

[0126] The third step: establish a kinetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com