Manufacturing method of trench type SGT-MOS device with low electric leakage and high stability

A device manufacturing method and high-stability technology, applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve problems such as large gate and source leakage, uneven dielectric thickness, and difficult thickness control. To achieve the effect of reducing leakage, good appearance, easy and stable appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

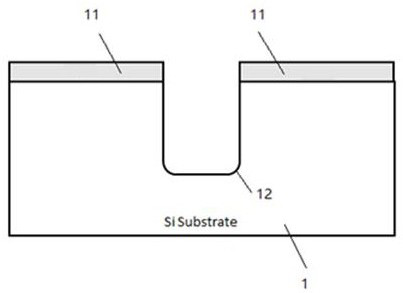

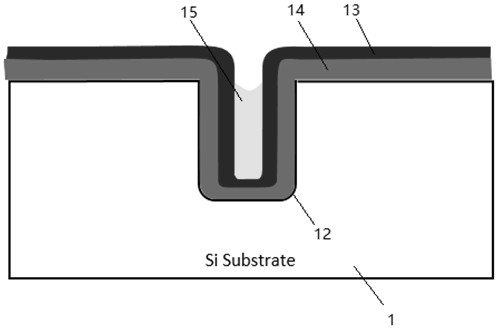

[0034] As shown in the figure, a trench type SGT-MOS device with low leakage and high stability, the epitaxial layer 1 of the device is provided with several trenches 12 built with polycrystalline solid 15; the polycrystalline solid is in the form of I-type structure; the bottom and the inner sidewall of the groove are provided with an insulating layer bonded to the polycrystalline solid; the top of the insulating layer at the inner sidewall of the groove is lower than the epitaxial layer, so that the insulating layer, the epitaxial layer and the sidewall of the polycrystalline solid surround two dielectric grooves 18 located at the sidewall of the I-type polycrystalline solid; the insulating layer is a combined structure including the first insulating structure 13 and the second insulating structure 14 .

[0035] The bottom of the dielectric groove is inclined toward the polycrystalline solid, and is in the shape of a slope or a step with a narrow top and a wide bottom; the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com