Spatial multilayer automatic breeding system and breeding method for hermetia illucens

A breeding system, black soldier fly technology, applied in animal husbandry, etc., to achieve high efficiency, less labor, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

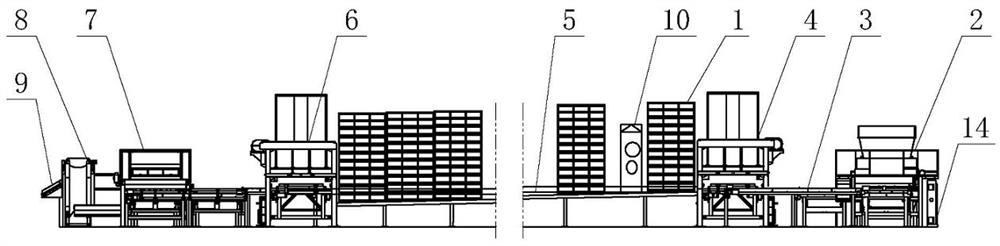

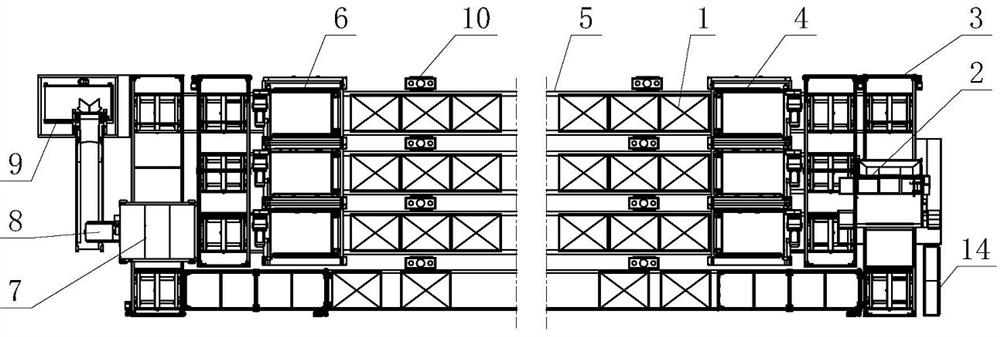

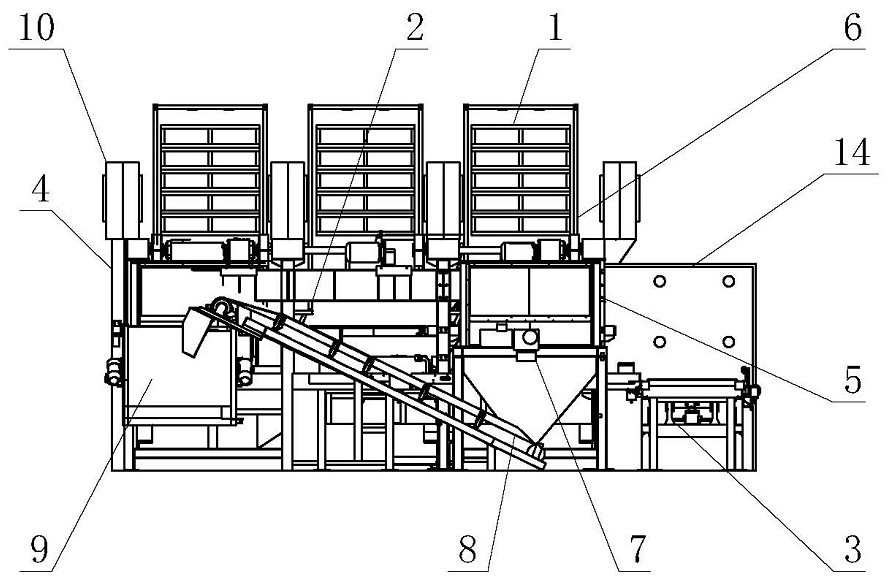

[0047] as attached Figure 1 to Figure 3As shown, the black soldier fly space multi-layer automatic breeding system of Embodiment 1 of the present invention is mainly composed of a breeding tray 1, a feed loading machine 2, a tray conveyor 3, a tray stacker 4, a tray conveyor unit 5, and a tray stacker. A tray machine 6, a tray turning machine 7, a material conveyor 8, a screening machine 9, a temperature regulating device 10 and a system controller 14 are formed; the culture feed is loaded into the culture tray 1 through the feed tray machine 2; The cultivation tray 1 is conveyed by the pallet conveyor 3; the cultivation tray 1 is stacked by the pallet stacker 4; the cultivation tray 1 is conveyed by the pallet conveyor unit 5; The breeding tray 1 is removed from the tray by the stacking and unloading machine 6; the black soldier fly larvae, insect droppings and slag in the breeding tray 1 are removed from the farming tray 1 by the turning and unloading machine 7. poured out...

Embodiment 2

[0051] see Figure 4 As shown, the black soldier fly space multi-layer automatic breeding system of embodiment two of the present invention is similar to embodiment one, the only difference is:

[0052] In order to reduce the manufacturing cost of the farming system, reduce the installation and usage of the pallet stacker 4 and the stacking and dismantling machine 6 in the farming system, increase the installation of the stacking reversing conveyor 11 in the farming system; The stacking reversing conveyor 11 is connected to the ends of four sets of stacking conveyor units 5 installed in parallel, wherein two sets of output ends of the stacking conveyor sets 5 and two sets of input ends of the stacking conveyor sets 5 , to realize the 180-degree reversing transportation of the aquaculture tray 1 on the tray conveyor unit 5 from the tray stacker 4 to the tray stacker 6, and the tray stacker Machine 4 and disc stacking and dismantling machine 6 are installed and operated at the ...

Embodiment 3

[0054] see Figure 5 As shown, the black soldier fly space multi-layer automatic breeding system of embodiment three of the present invention is similar to embodiment one, the only difference is:

[0055] In order to meet the technical needs of adding feed to the breeding tray 1 twice in the breeding cycle, the feed loading machine 2 in the breeding system is provided with two sets, which are installed in the stacking and dismantling machine 6 in series. and between the pallet stacker 4. When the stacks of the culture tray 1 are transported on the stack conveyor unit 5 for a certain period of time, the black soldier fly larvae consume the feed in the culture tray 1 and need to add feed to the culture tray 1 again. At this time, the system removes the breeding tray 1 from the trays one by one, adds feed again through the added feed tray machine 2, and then palletizes again through the tray palletizer 4. The stack conveyor unit 5 continues to convey (cultivation cycle) to meet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com