A desulfurization and denitrification waste liquid degradation treatment device

A treatment device, desulfurization and denitration technology, applied in the field of desulfurization and denitrification, can solve the problems of inability to mix chemicals with waste liquid, poor impurity removal effect, and affect subsequent use, so as to reduce labor intensity, avoid waste of chemicals, and prevent accumulation of impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

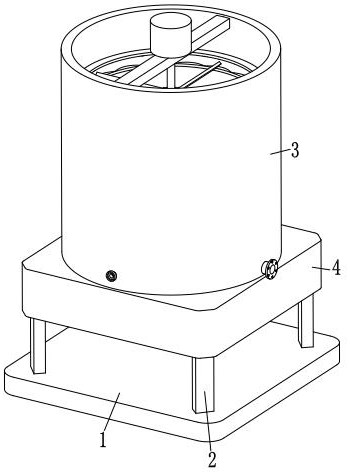

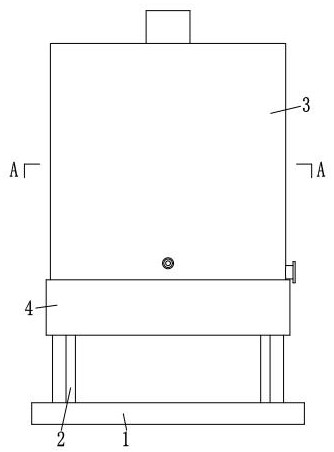

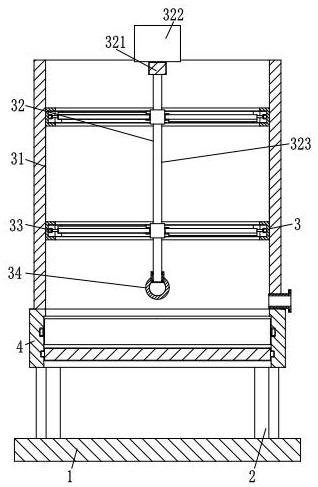

[0030] Such as Figure 1 to Figure 6 As shown, a desulfurization and denitrification waste liquid degradation treatment device includes a base frame 1, a support frame 2, a processing device 3 and a cleaning device 4. The upper end of the base frame 1 is evenly equipped with a support frame 2, and the upper end of the support frame 2 is fixed and installed There is a cleaning device 4, the cleaning device 4 has a rectangular structure, and a processing device 3 is installed on the upper end of the cleaning device 4.

[0031] The processing device 3 includes a fixed cylinder 31, a driving mechanism 32, a stirring mechanism 33, a feed pipe 34 and a liquid discharge pipe 35. The upper end of the cleaning device 4 is equipped with a fixed cylinder 31, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap