A kind of aluminum foil scraping guide device for capsule aluminum-plastic packaging machine

A technology of scratching and guiding and guiding device, applied in the field of capsule packaging, can solve the problems such as the inability to effectively improve the output of capsule packaging, the frequency of replacing the cutter, and the reduction of the cutting efficiency of the capsule, so as to save the pause time, reduce the frequency of replacement, and facilitate the the effect of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

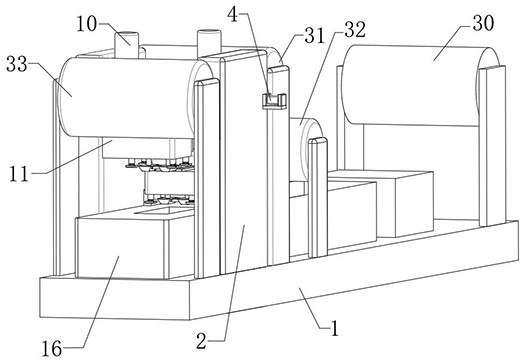

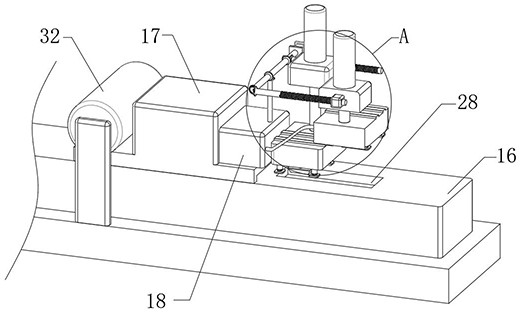

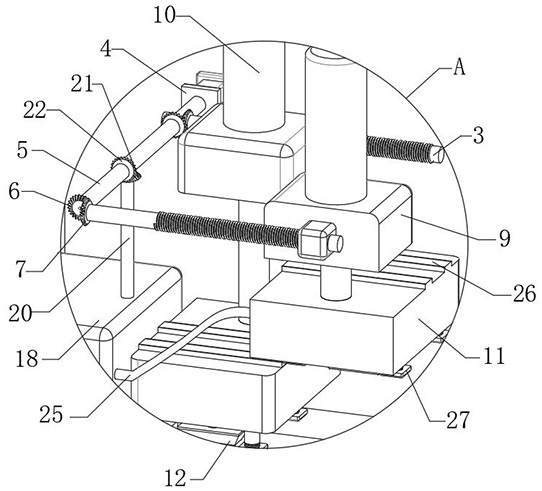

[0025] refer to Figure 1-9 , an aluminum foil scratching guide device for a capsule aluminum-plastic packaging machine, including a guide device arranged on a receiving platform 1, such as figure 1 and 2 As shown, the receiving platform 1 is also connected to the feed roller 30 through the bracket rotation, the aluminum foil roller 31, the guide roller 32, and the receiving roller 33, and the aluminum foil and the capsule plate are respectively wrapped on the feed roller 30 and the aluminum foil roller 31, and are passed through the guide roller. The roller 32 guides to the bottom of the guide device, and the guide device guides the cutter 12 to complete the cutting and packaging, and then the remaining waste is collected by the receiving roller 33. This is a mature cutting process in the prior art and does not belong to the protection of this application. Therefore, this application does not introduce too much about the existing technical features;

[0026] A processing se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com