Bottle unscrambling device and method

A bottle unscrambling device and clamping device technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as inaccurate positioning and influence on subsequent processes, and achieve the effect of avoiding accidental dumping and facilitating automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

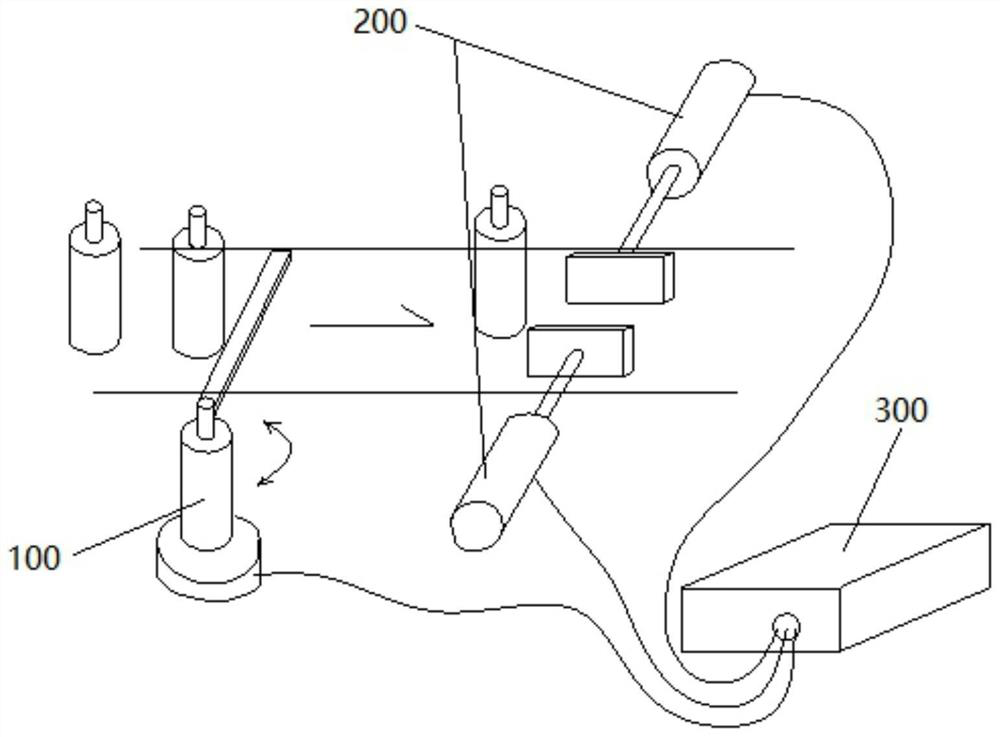

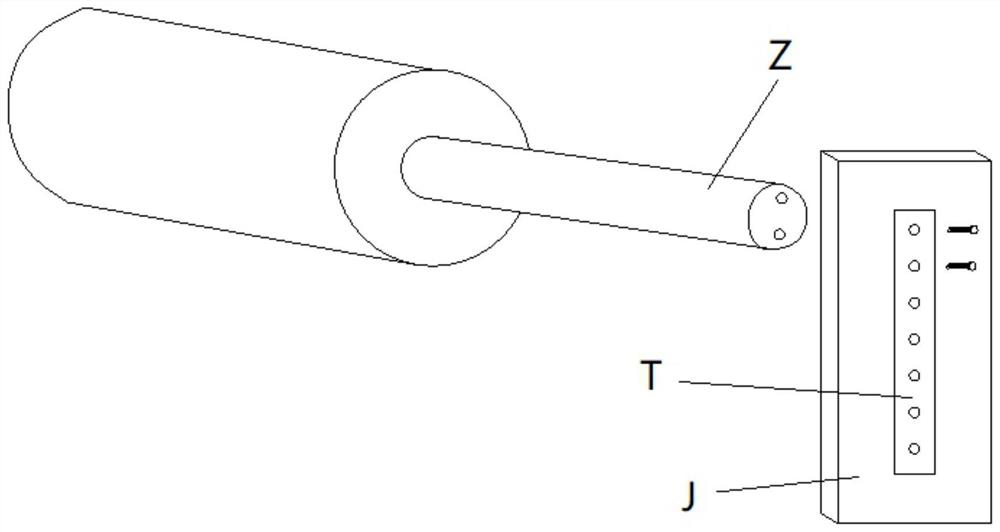

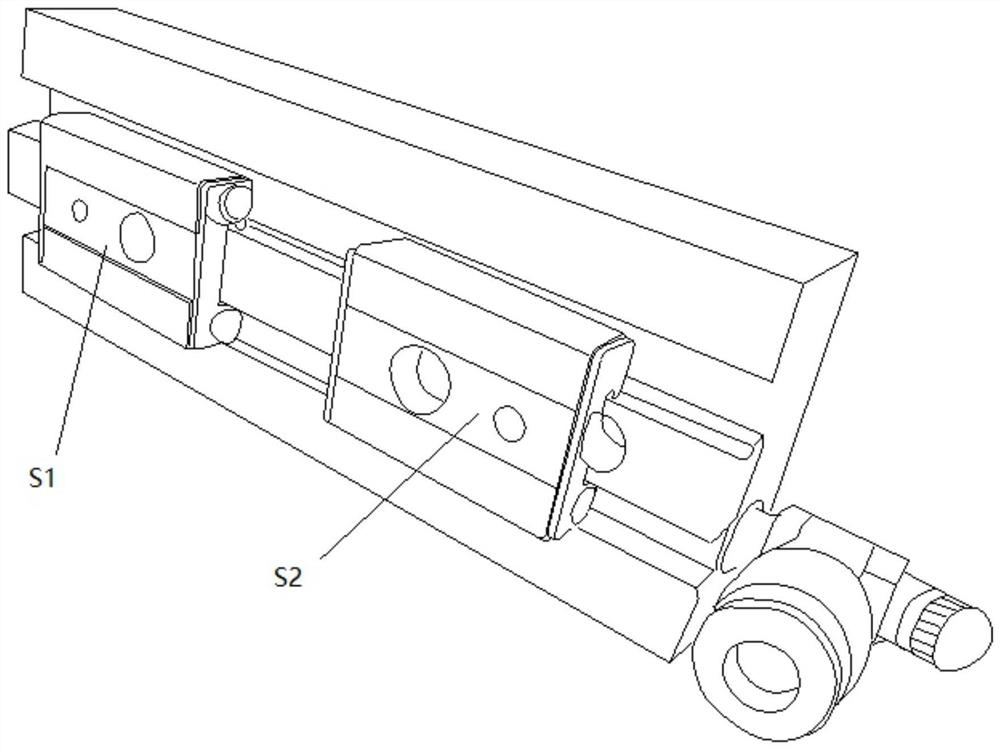

[0037] Such as figure 1As shown, the present invention provides a bottle unscrambling device, comprising: a first bottle blocking mechanism 100, a second bottle blocking mechanism 200, a controller 300 provided with a time relay; The mechanism 100 and the second bottle blocking mechanism 200 are electrically connected; relative to the direction of travel of the production line from the upstream end to the downstream end, the first bottle blocking mechanism 100 and the second bottle blocking mechanism 200 are successively arranged on the production line; the first The setting relationship between the bottle blocking mechanism 100 and the second bottle blocking mechanism 200 satisfies: the space formed between the first bottle blocking mechanism and the second bottle blocking mechanism can only accommodate one bottle; the first bottle blocking mechanism The blocking action timing of 100 is satisfied: when the second bottle arresting mechanism 200 unblocks, only one bottle is rel...

Embodiment 2

[0046] This embodiment further provides a method on the basis of Embodiment 1, the method includes the following steps:

[0047] Step 1: Set up the first bottle arresting mechanism 100 and the second bottle arresting mechanism 200 sequentially in the direction of travel from the upstream end to the downstream end of the production line; the normal state of the first bottle arresting mechanism 100 is an arresting state; the second bottle arresting mechanism The arresting state of the mechanism 200 is to periodically release the arresting of the bottle only at fixed time nodes, and quickly restore the arresting of the bottle after the arresting is released;

[0048] Step 2: By debugging the time relay in the controller, modify the time node when the second bottle blocking mechanism 200 periodically releases the bottle body, so that the second bottle blocking mechanism 200 meets when the production line is running: when the second bottle blocking mechanism 200 When the blocking i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com