Regeneration treatment method of waste transformer oil

A transformer oil and treatment method technology, applied in the direction of lubricating composition, etc., can solve the problems of unsmooth regeneration oil, resistance to popularization, lack of experience and operation mode, etc., and achieve the effect of low cost and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

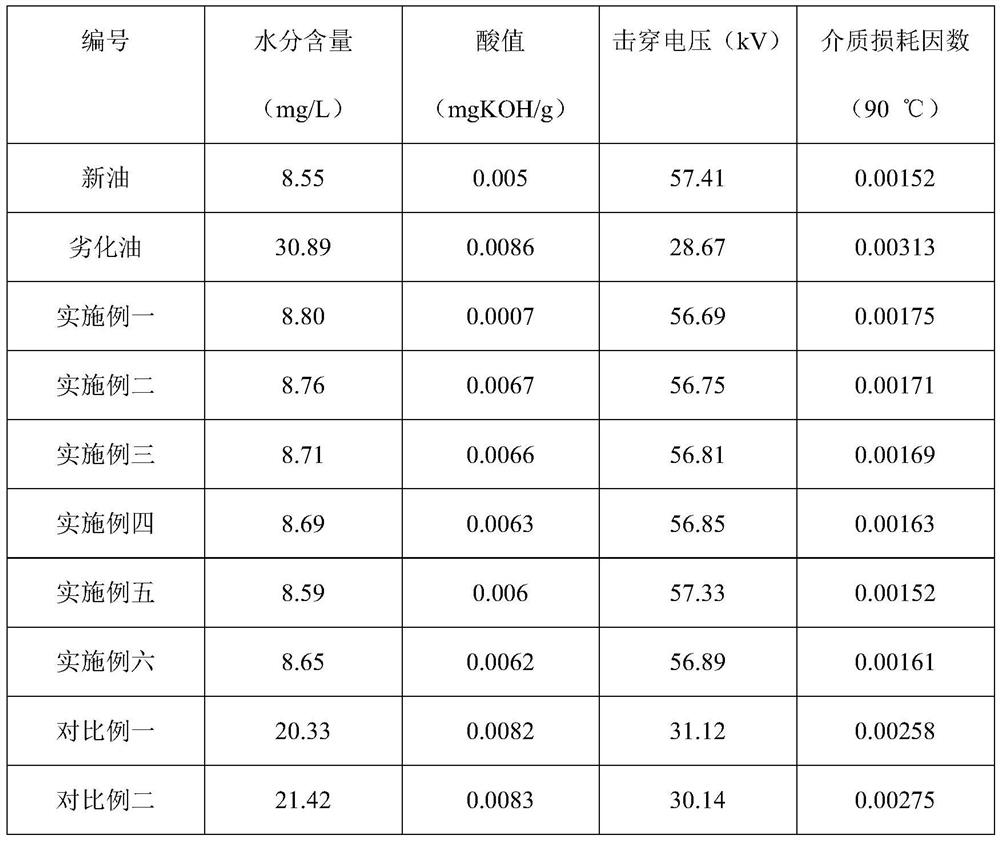

Embodiment 1

[0024] Example 1: After filtering the transformer waste oil with a rotary filter, add concentrated sulfuric acid according to the acid-oil mass ratio of 1:30, stir and heat to 40°C, and stop stirring after 3 hours. Filter to obtain primary purified oil and acid residue, add magnesium oxide to the supernatant clear oil, the mass ratio of solid to oil is 1:30, stir evenly at 30°C, and stop stirring after 3 hours. Filter to obtain secondary purified oil and alkali residue. Adsorbent is added to the secondary purification oil, and after a period of time, it is filtered and vacuum dehydrated to obtain regenerated oil. The resulting alkali slag and acid slag are neutralized and roasted in a ratio of 1:1, and the roasting temperature is 600°C. After this treatment, the process does not produce harmful waste to the environment.

Embodiment 2

[0025] Example 2: After filtering the transformer waste oil with a rotary filter, add concentrated sulfuric acid according to the acid-oil mass ratio of 1:25, stir and heat to 40°C, and stop stirring after 4 hours. Filter to obtain primary purified oil and acid residue, add magnesia to the supernatant clear oil with a solid-oil mass ratio of 1:25, stir evenly at 30°C, and stop stirring after 3 hours. Filter to obtain secondary purified oil and alkali residue. Adsorbent is added to the secondary purification oil, and after a period of time, it is filtered and vacuum dehydrated to obtain regenerated oil. The resulting alkali slag and acid slag are neutralized and roasted in a ratio of 1:1, and the roasting temperature is 650°C.

Embodiment 3

[0026] Example 3: After filtering the transformer waste oil with a rotary filter, add concentrated sulfuric acid according to the acid-oil mass ratio of 1:20, stir and heat to 30°C, and stop stirring after 5 hours. Filter to obtain primary purified oil and acid residue, add magnesium carbonate to the supernatant clear oil, the solid-oil mass ratio is 1:30, stir evenly at room temperature, stop stirring after 3 hours. Filter to obtain secondary purified oil and alkali residue. Adsorbent is added to the secondary purification oil, and after a period of time, it is filtered and vacuum dehydrated to obtain regenerated oil. The resulting alkali slag and acid slag are neutralized and roasted in a ratio of 1:1, and the roasting temperature is 600°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com