Heat treatment device for nodular cast iron piston casting

A heat treatment device, ductile iron technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of slow melting and heating of materials, inability to concentrate heat, and inability to preserve heat, so as to prevent burns, improve heat preservation, and avoid heat The effect of spreading out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

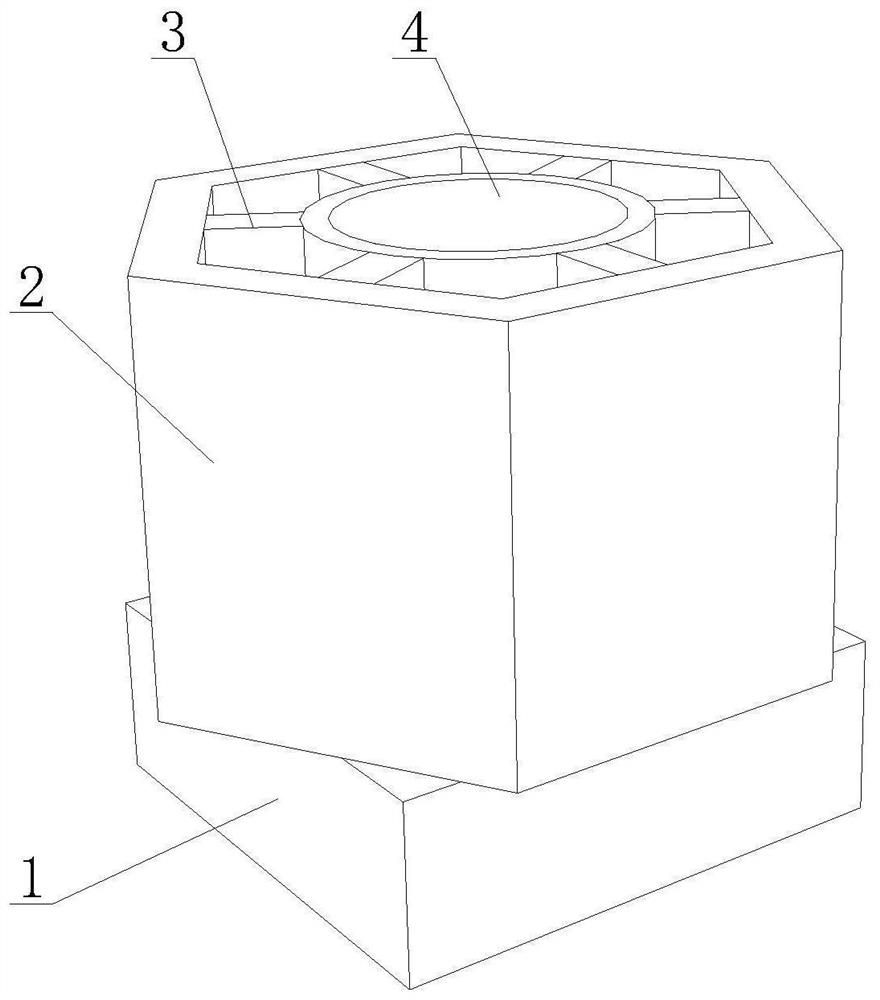

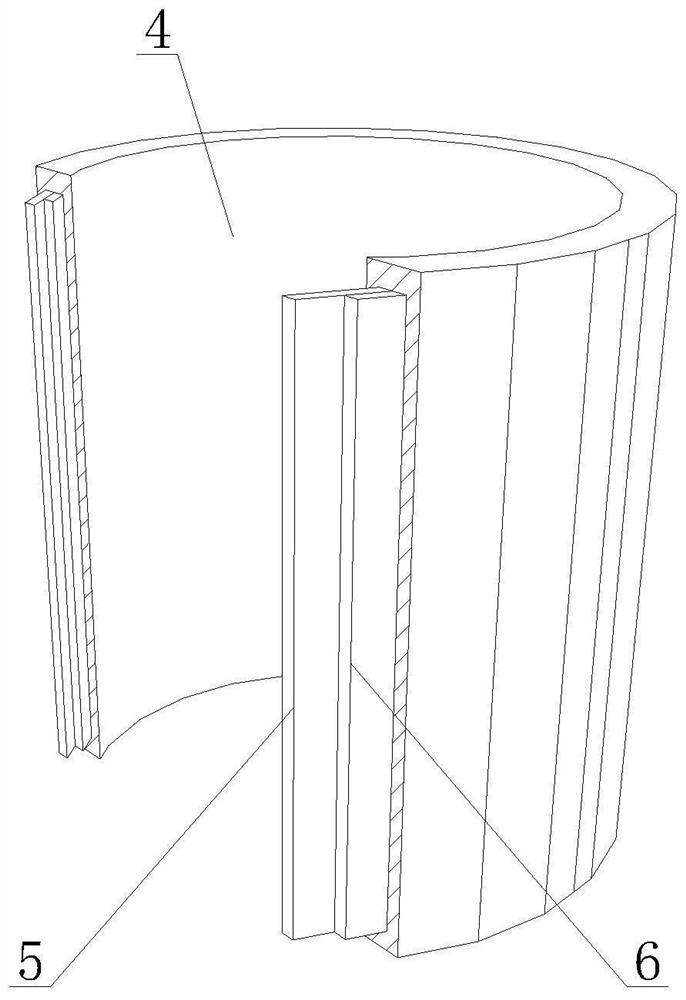

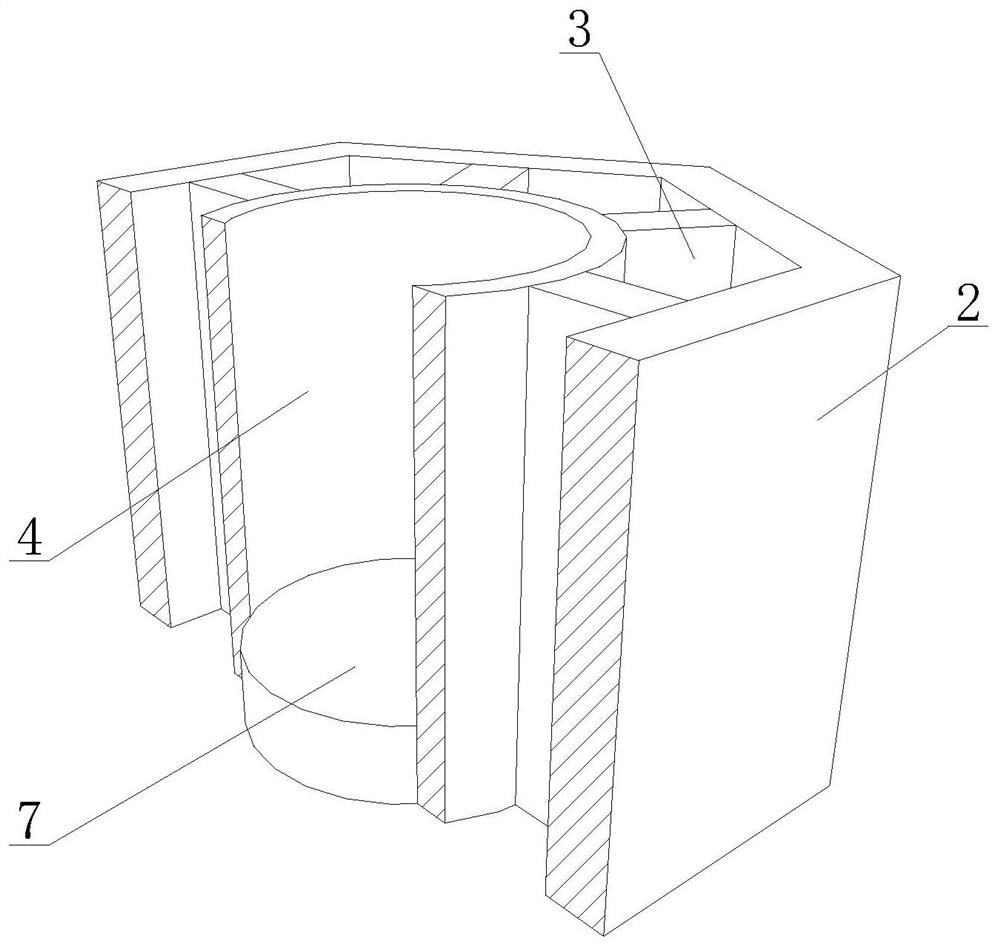

[0031] Such as Figure 1-Figure 5 As shown, the present invention provides a heat treatment device for ductile iron piston castings, comprising a heat treatment device main body 1, a heat insulation plate 2 and an insulation connection plate 3, the top of the heat treatment device main body 1 is fixedly installed with an insulation connection plate 3, and the insulation connection plate 3 is fixedly installed on the outer side of the heat insulating plate 2, the bottom of the insulating connection plate 3 is fixedly installed on the top of the heat treatment device main body 1, the heat treatment device main body 1 is electrically connected with the external power supply through the power cord, and the bottom of the heat insulating plate 2 is fixedly installed On the top of the heat treatment device main body 1, the inner side of the insulation connection plate 3 is fixedly installed with a heat treatment body 4, and the heat insulation plate 2 and the insulation connection pla...

Embodiment 2

[0033] Such as Figure 1-5As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a temperature anti-dispersion element plate 10 is fixedly installed around the inner wall of the high-efficiency melting main body 7, and the upper and lower ends of the temperature anti-dispersion element plate 10 are fixedly installed on the high-efficiency On the inner wall of the melting main body 7, the bottom of the inner wall of the high-efficiency melting main body 7 and the inner side of the temperature dispersion prevention element plate 10 are fixedly installed with a high-temperature heat concentration strip 8, and the top of the high-temperature heat concentration strip 8 is fixedly installed on the inner wall of the high-efficiency melting main body 7 A high-temperature absorption element 9 is fixedly installed in the middle of the inner wall of the high-efficiency melting main body 7, and the upper and lower ends of the high-temperature absorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com