Double-side feeding and double-side exhausting upper cotton box device

A cotton box, double-sided technology, applied in deburring devices, textiles and papermaking, fiber processing, etc., can solve problems such as unsmooth feeding of fibers, affecting the uniformity of cotton mat, uneven distribution of feeding and output fibers, etc. Achieve the effect of improving raw sliver index, solving unevenness and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make it easier for those skilled in the art to understand the present invention, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings.

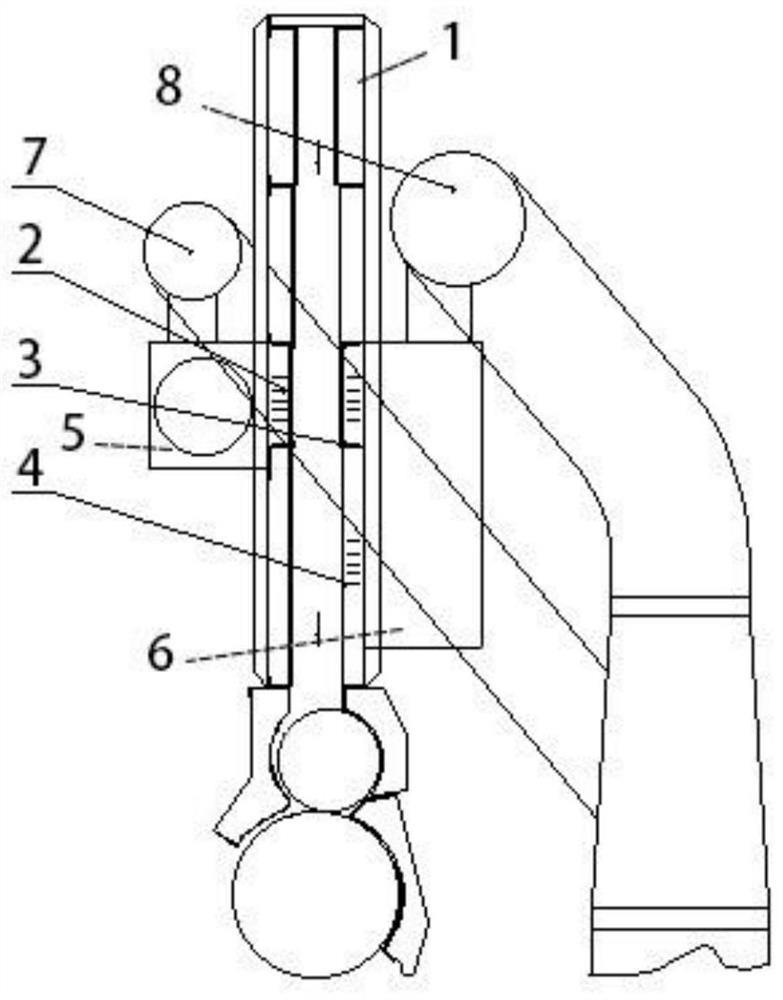

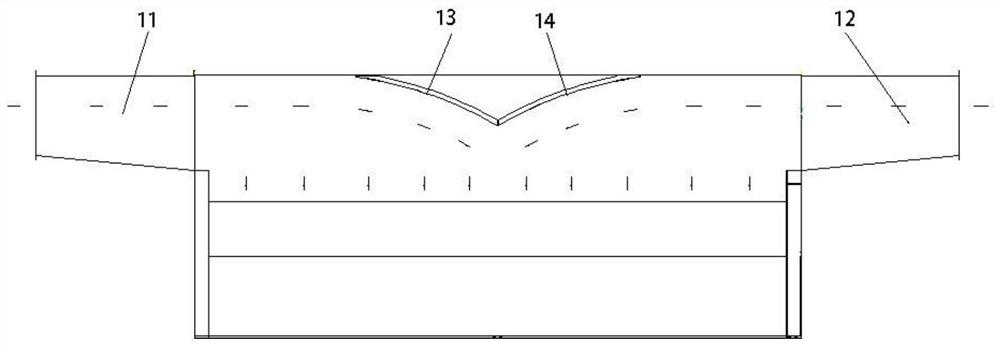

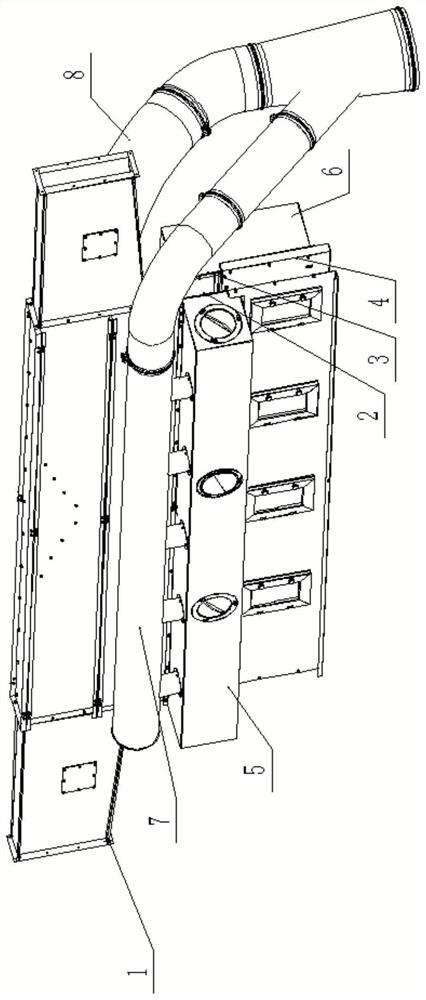

[0018] Such as Figure 1~6 Shown, a kind of upper cotton box 1 device of double-sided feeding and double-sided air exhaust, including upper cotton box 1, front carding needle plate 2, rear carding needle plate 3 and mesh plate 4; front carding needle plate 2 and rear combing The needle plate 3 is set on the lower side of the upper cotton box 1, and the mesh plate 4 is set on the lower side of the rear carding needle plate 3. The structure of the mesh plate 4 is added to ensure that the air volume entering the upper cotton box 1 can be smoothly discharged, solving the problem of The problem of the swirling air flow of the upper cotton box 1 and the failure of fibers to fall is solved; the outer sides of the front card board 2, the rear card board 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com