External throwing frame protection method

A scaffolding and floor-standing technology, which is applied in the field of external throwing protection, can solve the problems of high cost of section steel overhangs, affecting the layout of the inner frame support system of the roof layer, etc., and achieve the effect of ensuring safety protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further illustrated below by specific examples.

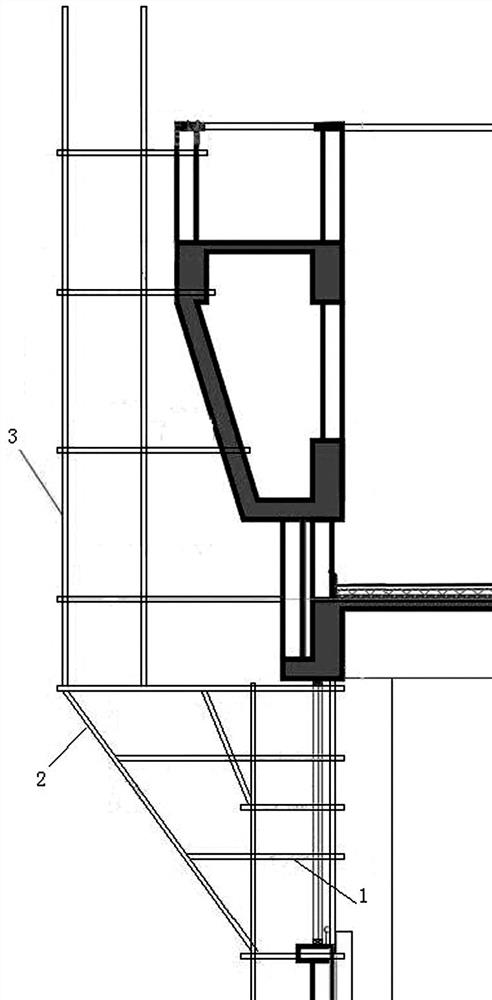

[0016] Such as figure 1 As shown, a protective method for external throwing frame, the protection method includes the lower floor type steel pipe scaffolding (1); the external throwing frame system (2); the upper external throwing protective scaffolding (3); specifically includes

[0017] Step 1. Erection of floor-to-ceiling scaffolding (1);

[0018] Step 2. Set up the outer throwing frame system (2);

[0019] Step 3, erecting the upper protective scaffolding;

[0020] in,

[0021] When working in step 1, the floor-standing scaffolding (1) is erected with steel pipes with a wall thickness not less than 3.0mm, and the scaffolding is erected to the next floor of the roof layer, and the erection distance is based on the distance calculated by Pinming software;

[0022] When working in step 2, the external throwing frame system (2) is diagonally braced on the lower layer of the roof layer to conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com