Geothermal well drilling well forming device and construction technology thereof

A technology for geothermal wells and drill bits, which is applied to driving devices, drilling tools, and drilling equipment for drilling in the wellbore, can solve the problems of unfavorable long-term use of geothermal wells, collapse of the sidewalls of geothermal wells, etc. Utilization rate and the effect of improving the efficiency of well formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

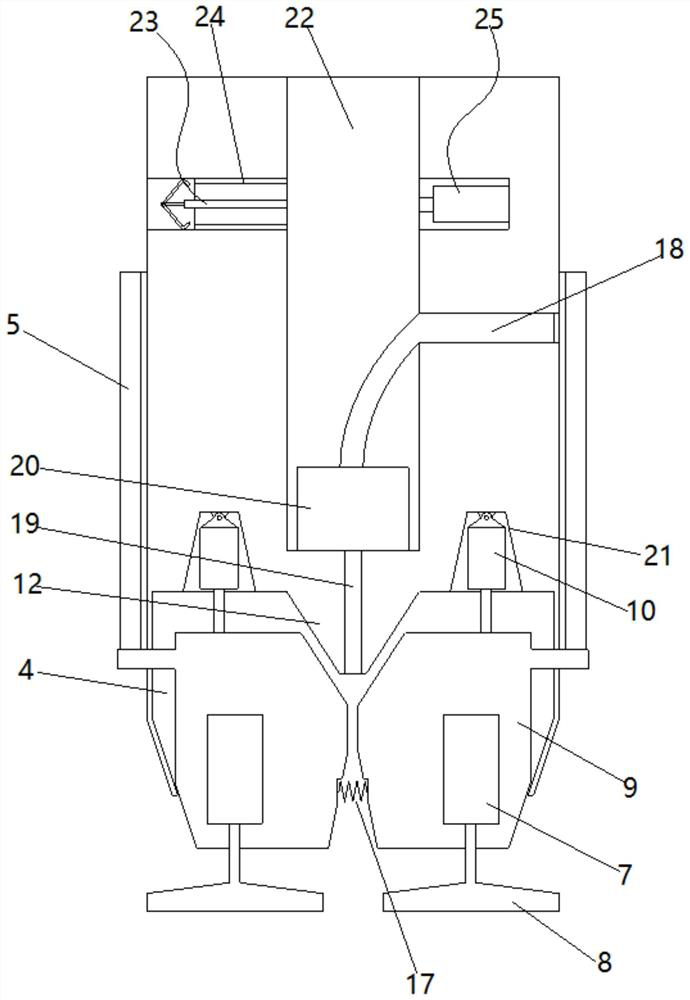

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

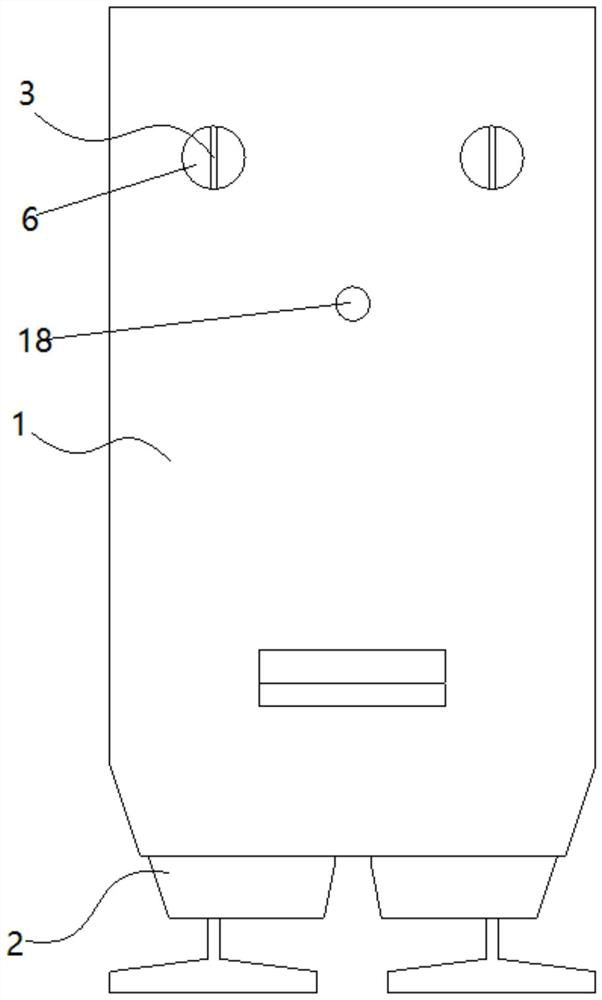

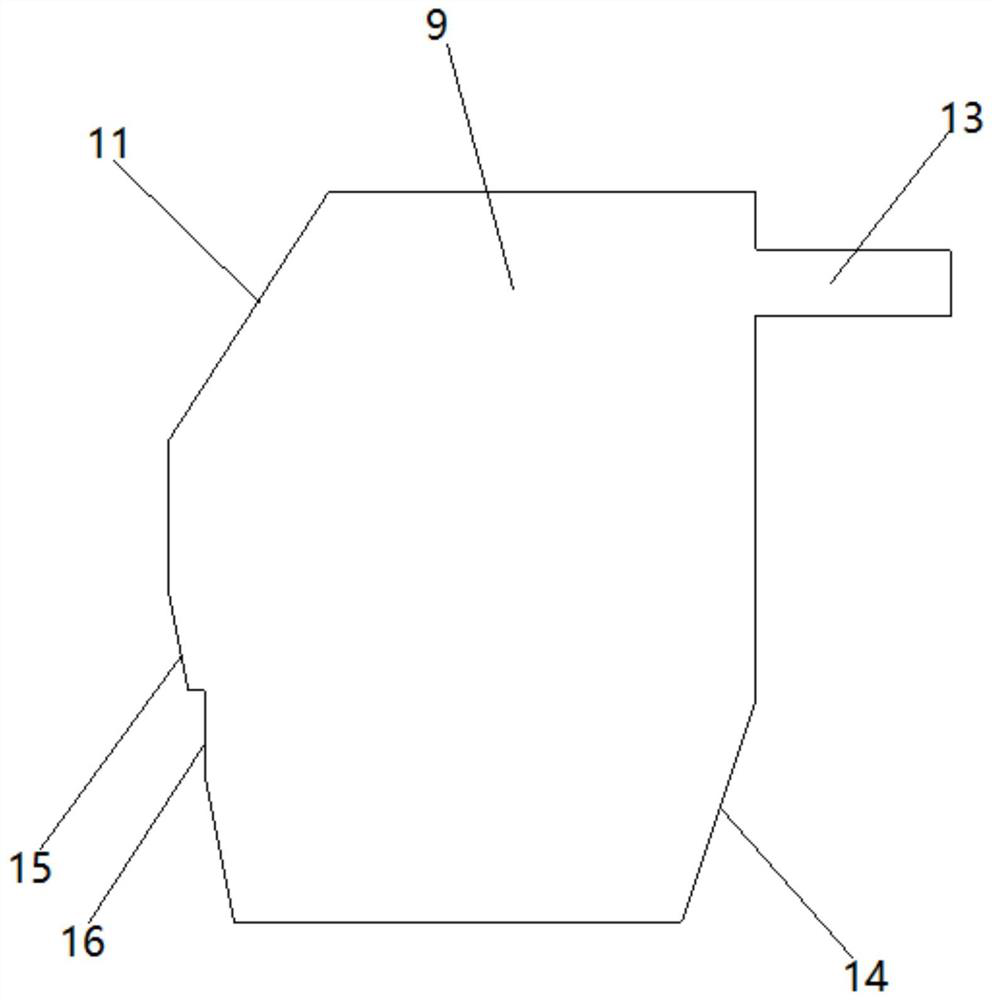

[0031] A device for drilling a geothermal well, comprising a drill sleeve 1, a drill assembly 2 and a drilling assembly 3, a drill cavity 4 is dug on the end surface of the drill sleeve 1, the drill assembly 2 is slidably installed in the drill cavity 4, and the drill The radial sliding of the assembly 2 relative to the drill sleeve 1 is convenient for shrinking the drill assembly 2 when recovering the device, preventing the drill assembly 2 from interfering with the geothermal well support tube 5, and the side wall of the drill sleeve 1 is dug with a side hole 6. The measuring and drilling assembly 3 is telescopically installed in the side hole 6. During the construction process, the geothermal well support tube 5 is set on the outside of the drill bit sleeve 1, so that the geothermal well support tube 5 goes down together with the device to form a well. , prevent the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap