Motor driving device for driving revolution and rotation of eccentric cutterhead

A motor-driven, cutter head technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of single cross-sectional shape and single mode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

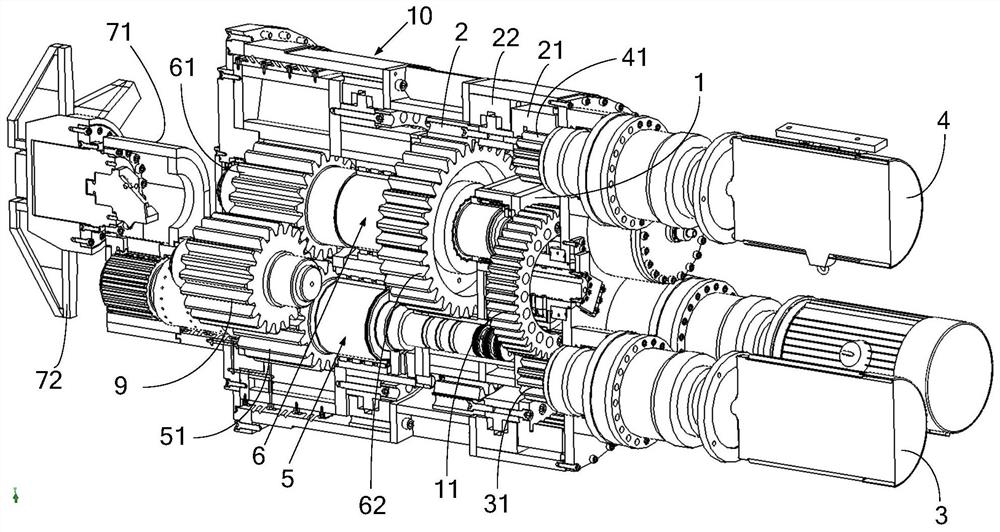

[0017] In order to solve the problem that the revolution speed and rotation speed of the output shaft are relatively fixed and the shape of the cutting section is single in the traditional cutter head drive mode, the present invention provides a motor drive device for driving the revolution and rotation of the eccentric cutter head, which can respectively realize the output The free adjustment of the rotation speed and revolution speed of the shaft, combined with the rotation of the cutterhead itself, can realize cutting of different cross-sectional shapes on the same machine.

[0018] The motor drive device for driving the revolution and rotation of the eccentric cutter head will be further described below with reference to the accompanying drawings in specific embodiments.

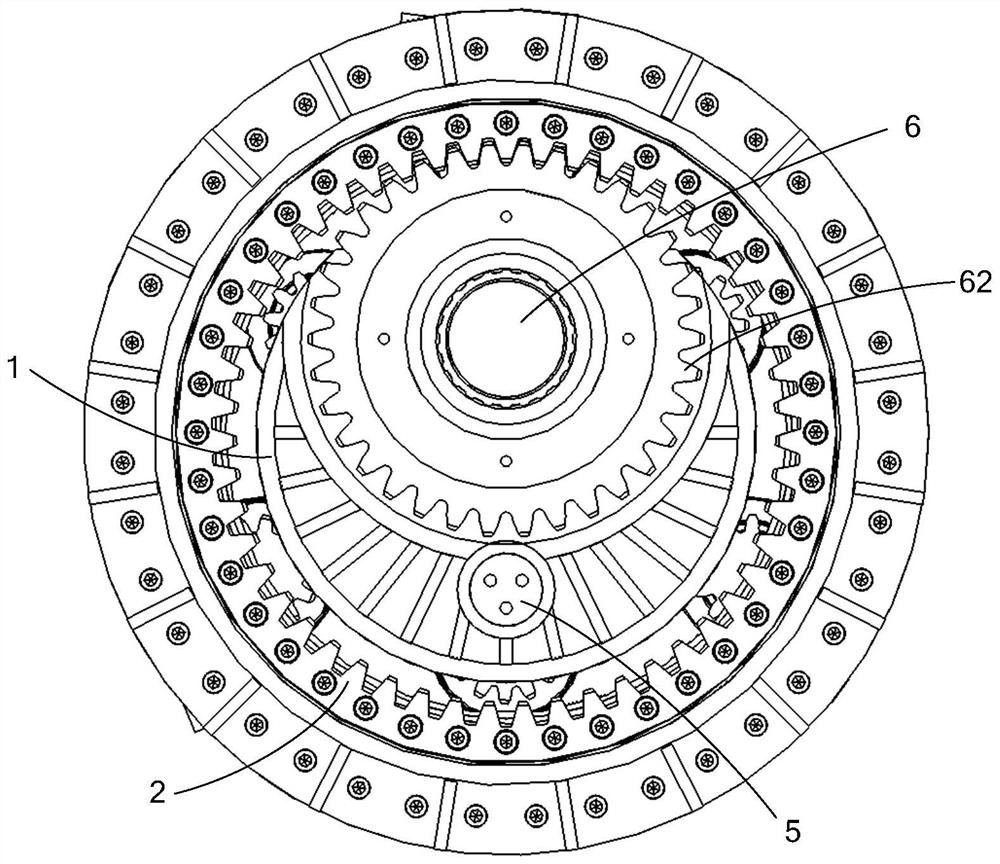

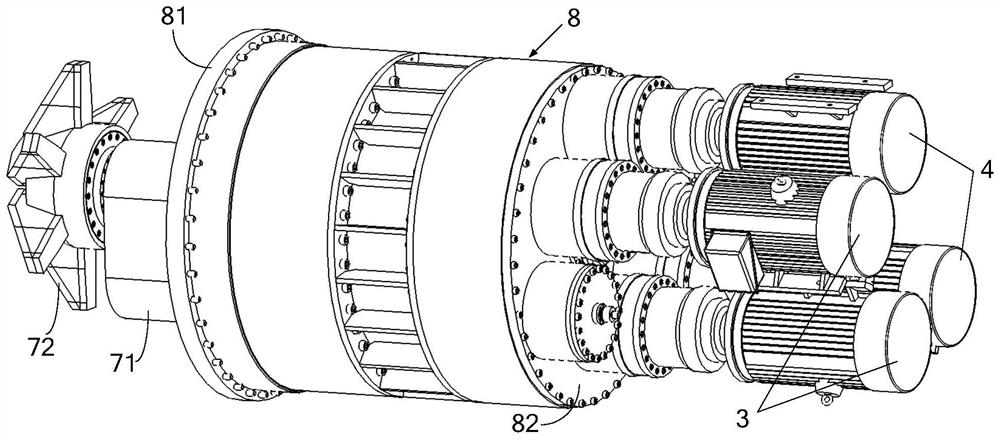

[0019] refer to Figure 1 ~ Figure 3 , figure 1 A schematic diagram showing the positional relationship of the central turntable, the first gear ring, the input shaft, the output shaft and the planetary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com