Range hood inlet triple-eccentric high-temperature cut-off butterfly valve

A triple eccentric and butterfly valve technology, applied in the field of control valves, can solve the problems of inconvenient use, low degree of automation, complex control equipment, etc., and achieve the effect of convenient application, fast and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

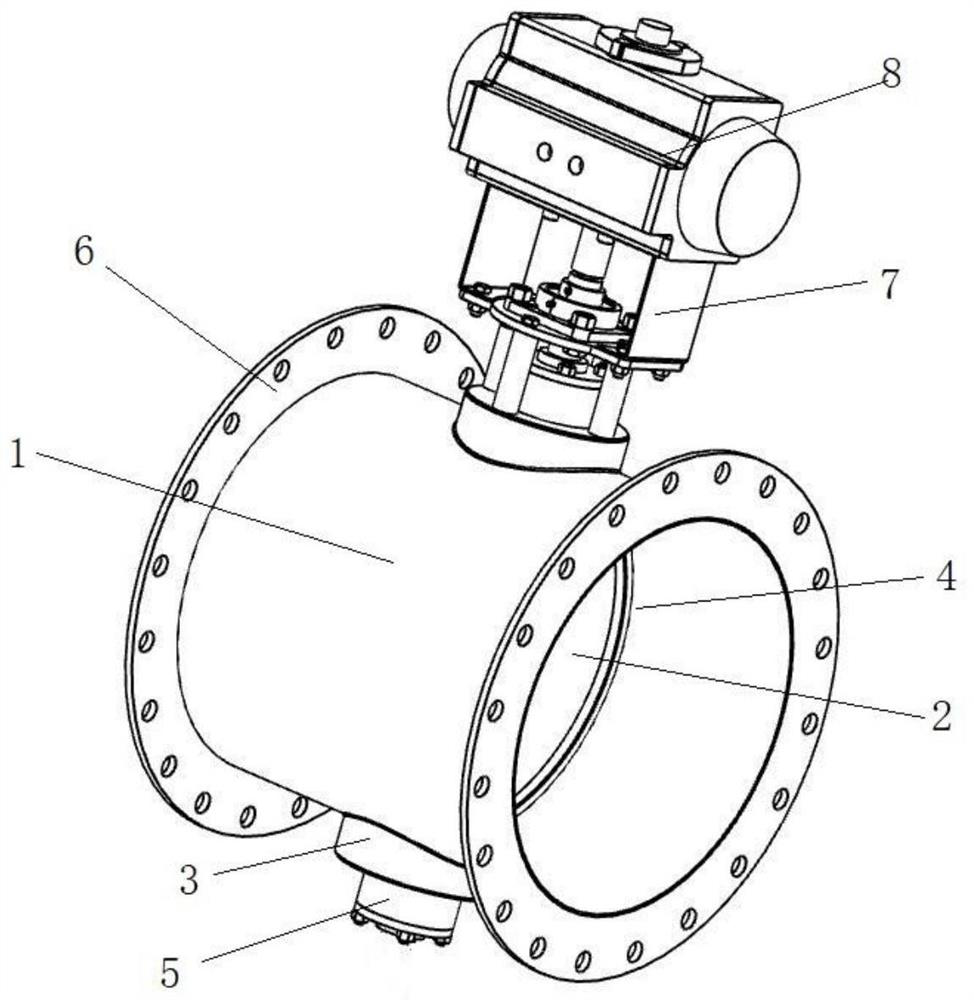

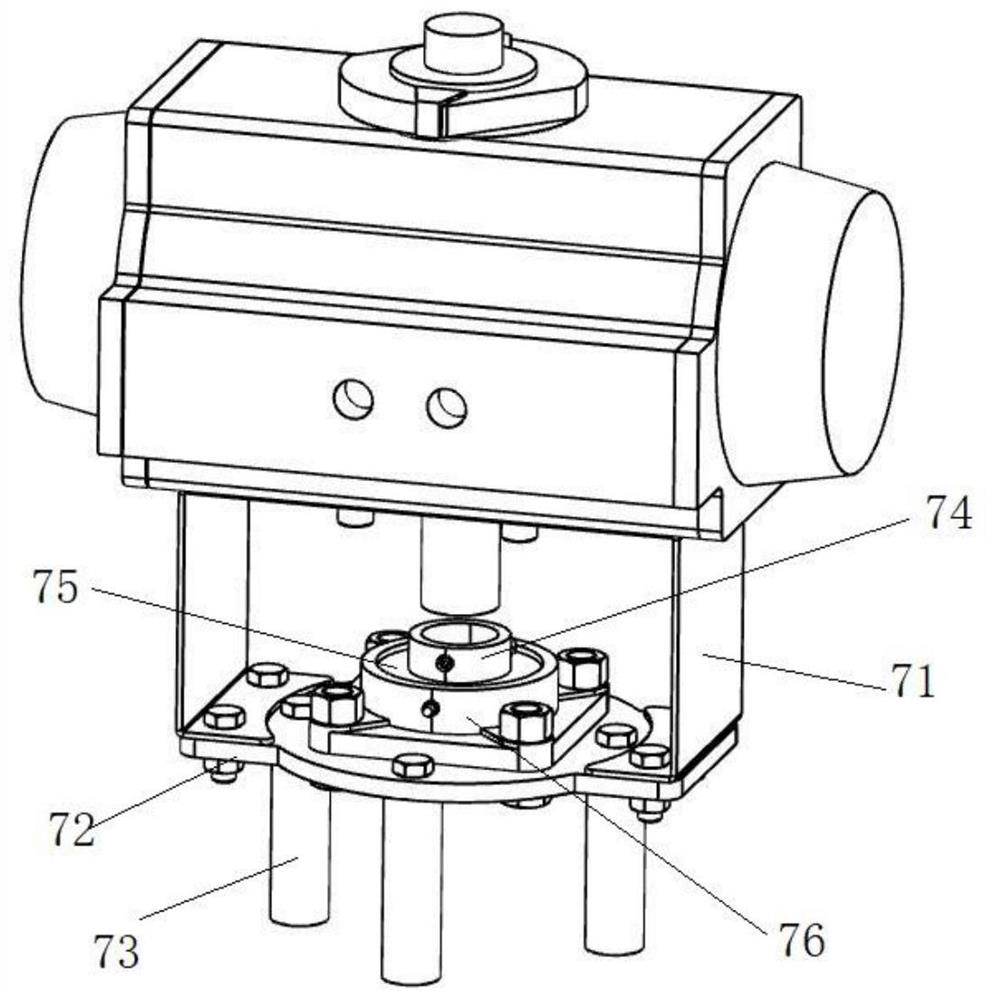

[0017] Such as Figure 1~3 As shown, the three-eccentric high-temperature cut-off butterfly valve at the entrance of the hood includes: a cut-off butterfly valve housing 1, a butterfly plate 2 is arranged inside the cut-off butterfly valve shell 1, and the butterfly plate 2 is installed on the drive shaft of the butterfly plate. The two ends of the plate drive shaft are installed on the drive shaft mounting platform 3 on the cut-off butterfly valve housing 1 through the butterfly plate drive shaft mounting seat 5, and one end of the butterfly plate drive shaft is connected to the output end of the drive motor 8 of the cut-off butterfly valve through a coupling Above, the casing of the cut-off butterfly valve drive motor 8 is installed on the cut-off butterfly valve housing 1 through the butterfly plate drive device mounting seat 7, and the butterfly plate drive device mount 7 includes a drive motor mounting frame 71, and the drive motor is installed The lower end of the frame ...

Embodiment 2

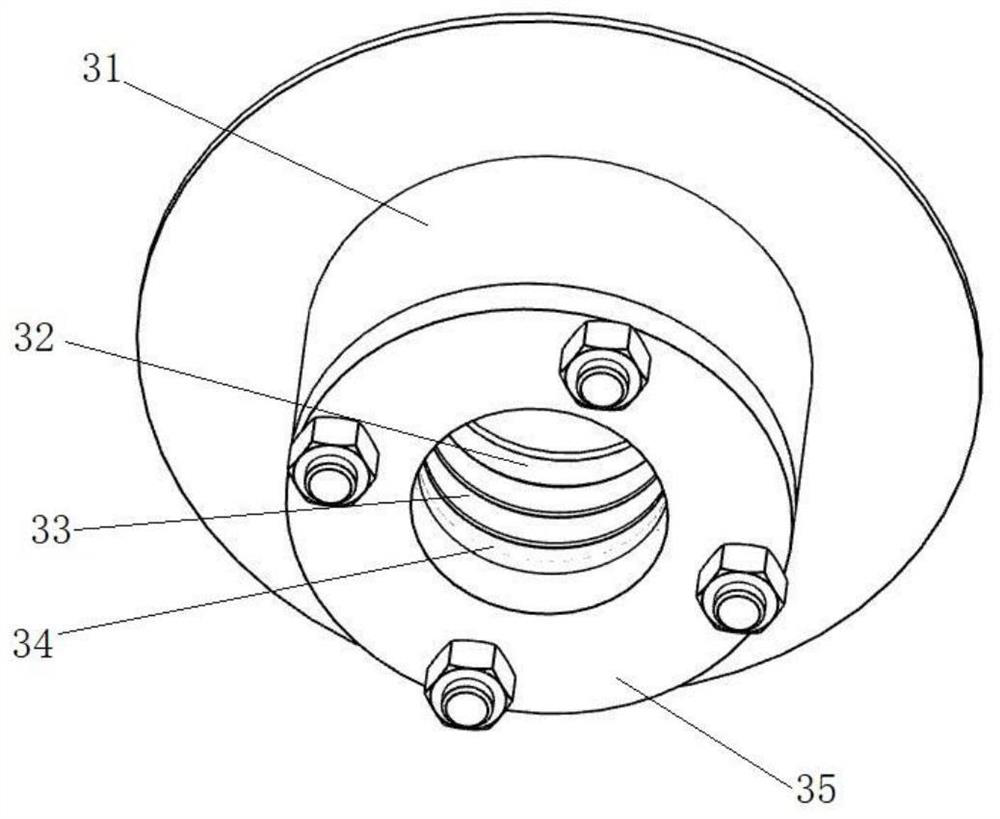

[0019] Such as Figure 1~3 As shown, the three-eccentric high-temperature cut-off butterfly valve at the entrance of the hood includes: a cut-off butterfly valve housing 1, a butterfly plate 2 is arranged inside the cut-off butterfly valve shell 1, and the butterfly plate 2 is installed on the drive shaft of the butterfly plate. The two ends of the plate drive shaft are installed on the drive shaft mounting platform 3 on the cut-off butterfly valve housing 1 through the butterfly plate drive shaft mounting seat 5, and one end of the butterfly plate drive shaft is connected to the output end of the drive motor 8 of the cut-off butterfly valve through a coupling Above, the casing of the cut-off butterfly valve driving motor 8 is installed on the cut-off butterfly valve casing 1 through the butterfly plate drive device mounting seat 7, and the butterfly plate drive shaft mounting seat 5 includes a drive shaft mounting bearing 33, and the drive shaft is installed The bearing 33 is...

Embodiment 3

[0021] Such as Figure 1~3 As shown, the three-eccentric high-temperature cut-off butterfly valve at the entrance of the hood includes: a cut-off butterfly valve housing 1, a butterfly plate 2 is arranged inside the cut-off butterfly valve shell 1, and the butterfly plate 2 is installed on the drive shaft of the butterfly plate. The two ends of the plate drive shaft are installed on the drive shaft mounting platform 3 on the cut-off butterfly valve housing 1 through the butterfly plate drive shaft mounting seat 5, and one end of the butterfly plate drive shaft is connected to the output end of the drive motor 8 of the cut-off butterfly valve through a coupling Above, the casing of the cut-off butterfly valve drive motor 8 is installed on the cut-off butterfly valve casing 1 through the butterfly plate drive device mounting seat 7, and the drive shaft mounting table 3 is welded and fixed on the cut-off butterfly valve casing 1. The butterfly plate The drive shaft mount 5 is mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com