Fault positioning method suitable for electric power equipment

A power equipment and fault location technology, applied in the direction of constraint-based CAD, genetic rules, electrical digital data processing, etc., can solve the problems of manual judgment, reduce the accuracy and efficiency of intelligent diagnosis, and achieve the effect of high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

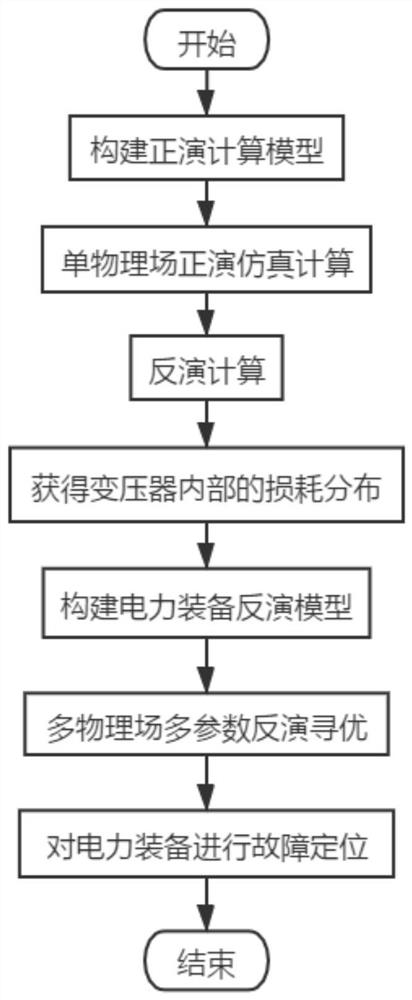

[0036] refer to figure 1 , which is the first embodiment of the present invention, this embodiment provides a fault location method suitable for electric equipment, including:

[0037] S1: Construct a forward calculation model based on the multi-physics simulation strategy, and perform forward simulation calculations for each single physical field inside the power equipment through the forward calculation model.

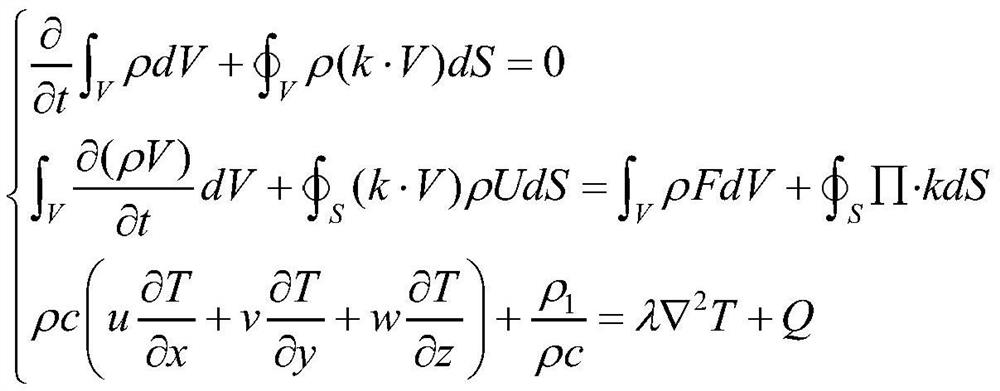

[0038]When analyzing the temperature field, it is necessary to consider the influence of various factors such as fluid, solid and heat transfer on the temperature at the same time. Based on the multi-physics simulation strategy and satisfying the law of conservation of mass, law of momentum conservation and law of energy conservation, the internal temperature field of the transformer is established. The forward calculation model of :

[0039]

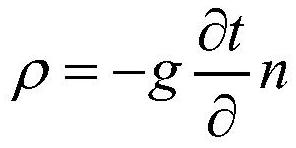

[0040] The fluid density ρ is:

[0041]

[0042] Among them, g is the thermal conductivity of the fluid, t is the su...

Embodiment 2

[0079] In order to verify and explain the technical effect adopted in this method, this embodiment chooses the traditional power equipment fault location method and adopts this method to conduct a comparative test, and compares the test results by means of scientific demonstration to verify the real effect of this method.

[0080] The traditional power equipment fault location method performs simple threshold segmentation or watershed algorithm on the infrared thermal image of power equipment to segment the hot parts. The hot parts segmented by this method often contain many non-interest region images or lose many interest region images. Seriously affect the accuracy of hot spot identification, seriously reducing the accuracy and efficiency of the entire intelligent diagnosis.

[0081] In order to verify that this method has a higher fault location accuracy than the traditional power equipment fault location method, in this embodiment, the traditional power equipment fault loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com