Industrial product defect intelligent detection method and device and computer storage medium thereof

A technology of intelligent detection and industrial products, which is applied in computing, image data processing, instruments, etc., can solve the problems of inability to obtain accurate characteristic parameters of targets, inability to meet customers' precise and high-speed detection requirements, and inability of accuracy rate to stably reach recognition rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

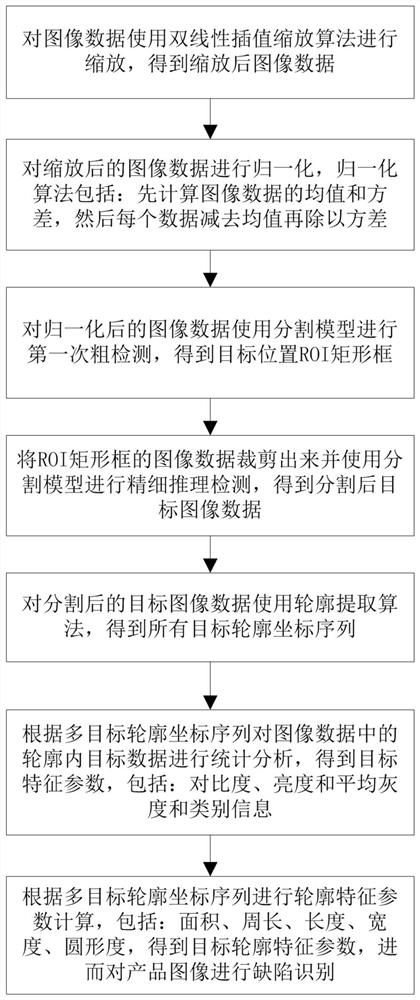

[0028] This embodiment provides an intelligent detection method for industrial product defects based on the combination of traditional machine learning and deep learning. The camera head obtains), and the image data is transmitted to the memory of the PC terminal, and the PC terminal processor of this embodiment processes the image data in the memory for the X86 processor; then, the X86 processor (the processor includes but is not limited to CPU, GPU, FPGA , ASIC processor) to process the image data, such as figure 1 As shown, it specifically includes the following steps:

[0029] Step 1: Scale the image data using a bilinear interpolation scaling algorithm to obtain the scaled image data;

[0030] Step 2: Normalize the scaled image data. The normalization algorithm includes: first calculate the mean and variance of the image data, and then subtract the mean from each data and divide by the variance;

[0031] Step 3: Use a segmentation model (for example, a UNet++ model) to ...

Embodiment 2

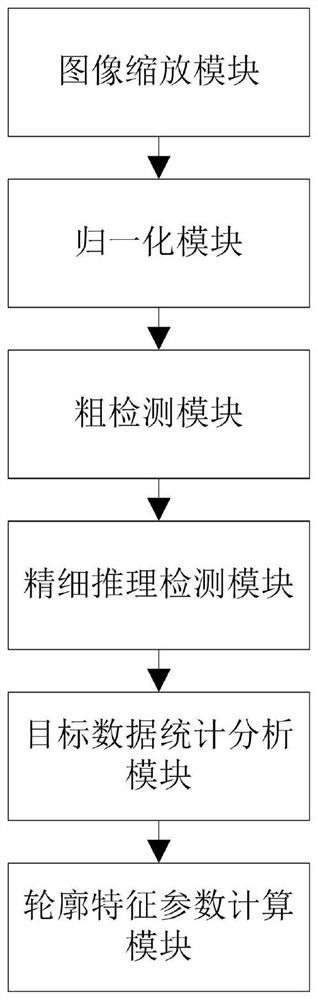

[0039] The invention provides an intelligent detection device for industrial product defects based on the combination of traditional machine learning and deep learning, such as figure 2 shown, including:

[0040] The image scaling module is used to scale the image data using a bilinear interpolation scaling algorithm to obtain the scaled image data;

[0041] A normalization module is used to normalize the scaled image data. The normalization algorithm includes: first calculating the mean and variance of the image data, and then subtracting the mean from each data and dividing by the variance;

[0042] Coarse detection module, for using segmentation model (for example, can be UNet++ model) to carry out first rough detection to the image data after normalization, obtains target position ROI rectangular frame;

[0043] The fine inference detection module is used to cut out the image data of the ROI rectangular frame and use the segmentation model (UNet++ model) to carry out fin...

Embodiment 3

[0050] The present invention provides a computer-readable storage medium, such as image 3 As shown, a computer program is stored thereon, and when the program is executed by a processor, the method described in the first embodiment is realized.

[0051]Those skilled in the art should understand that the embodiments of the present invention may be provided as methods, apparatuses, or computer program products. Accordingly, the present invention can take the form of an entirely hardware embodiment, an entirely software embodiment, or an embodiment combining software and hardware aspects. Furthermore, the present invention may take the form of a computer program product embodied on one or more computer-usable storage media (including but not limited to disk storage, CD-ROM, optical storage, etc.) having computer-usable program code embodied therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com