Wire retaining ring at the mouth of the sliding universal joint

A steel wire retaining ring and universal joint technology, which is applied in the direction of connecting components, household appliances, and other household appliances, can solve the problems of shell lengthening, adverse effects, and increased difficulty, so as to reduce the length of the shell and lengthen the slippage Effect of distance, material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

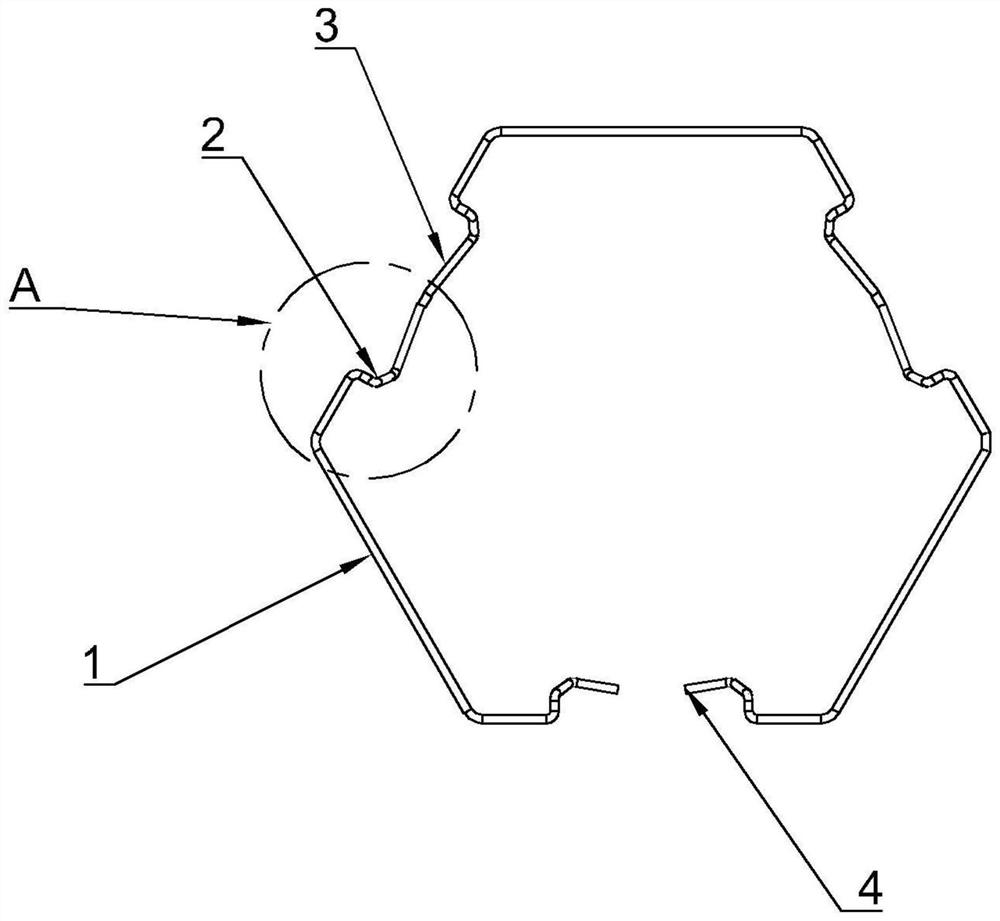

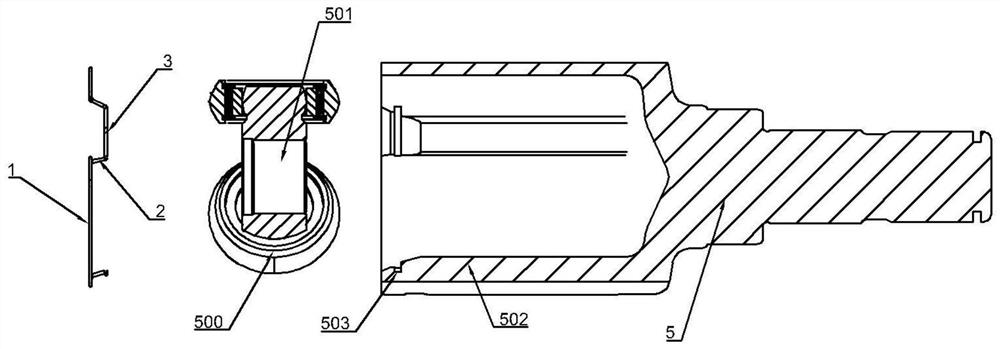

[0025] The wire retaining ring at the mouth of the sliding universal joint described in this embodiment, such as Figure 1 to Figure 7 As shown, in order to achieve the above-mentioned purpose, the sliding universal joint mouth wire retaining ring designed by the present invention includes a ring-shaped retaining ring main body, and the retaining ring main body includes a plurality of outer ring parts 1, a plurality of connecting part 2 and a plurality of embedded parts 3 embedded in the universal joint housing 5, the outer ring part 1 and the embedded part 3 are located on different planes, and the outer ring part 1, the connecting part 2 and the embedded part 3 are spaced in sequence And end-to-end connection, one of the embedded parts 3 is provided with an opening 4 .

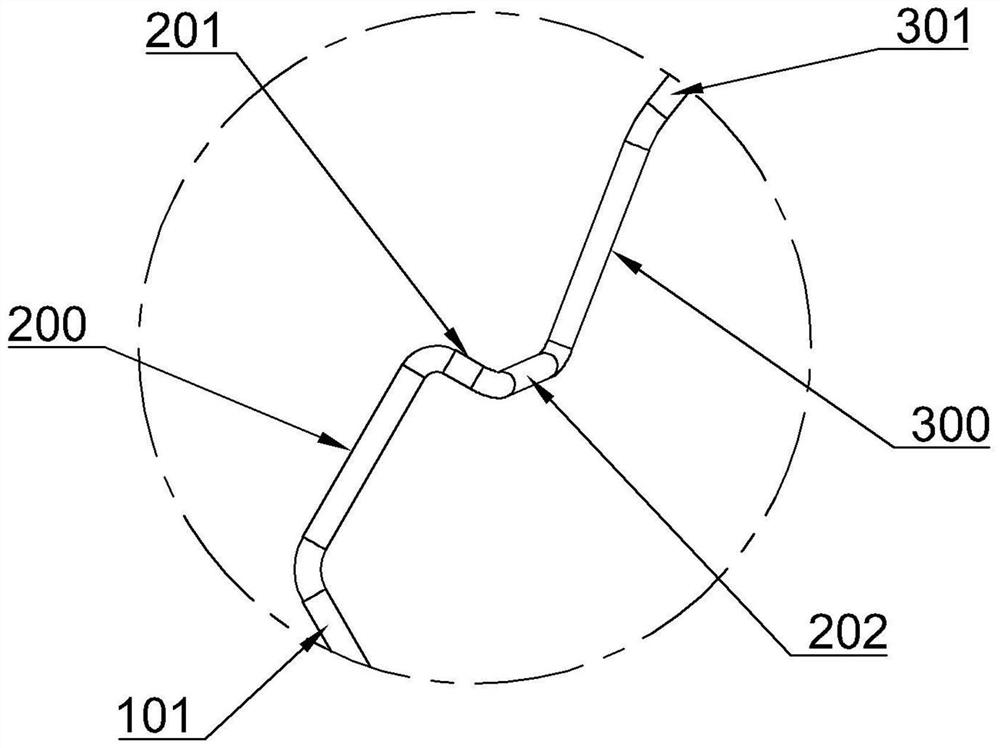

[0026] like figure 2 As shown, in order to extend the movement path of the ball ring, the outer ring portion 1 includes a first segment 100 of the outer ring portion and a second portion 101 of the outer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com