Intelligent numerical control cutter based on wireless transmission technology

A wireless transmission and technology technology, applied in the field of CNC machine tools, can solve the problems of limited cutting direction, inaccurate angle control, manual manual adjustment, etc., and achieve the effect of preventing accidental rotation, ensuring accuracy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

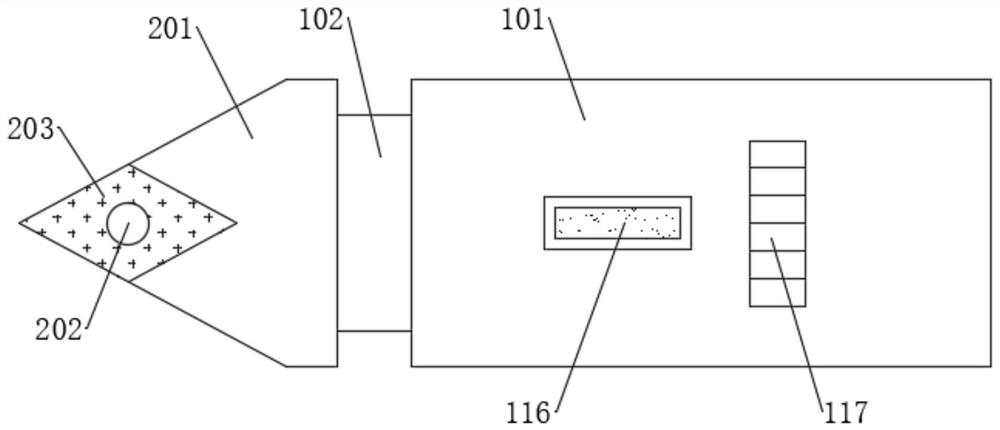

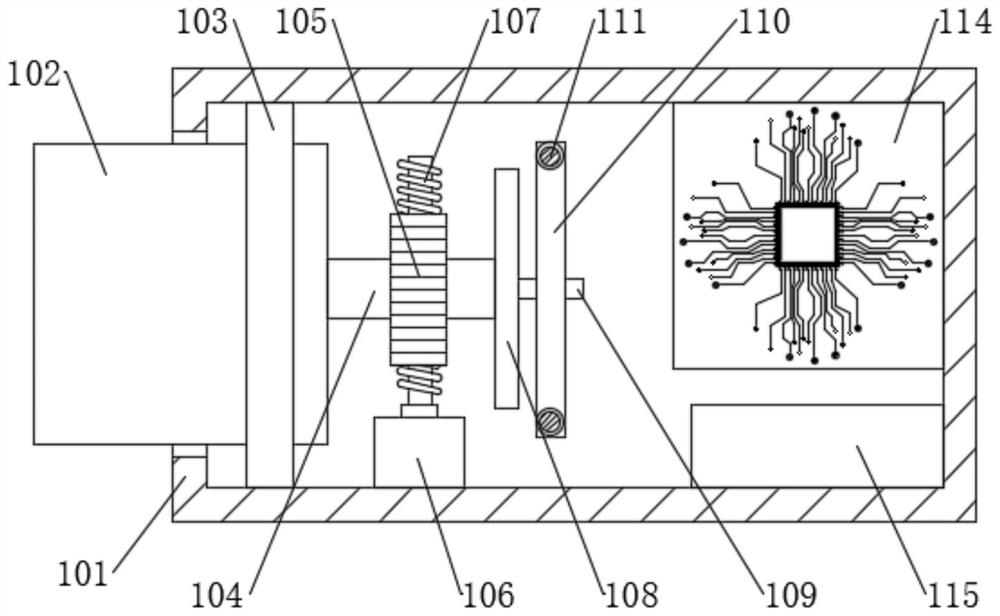

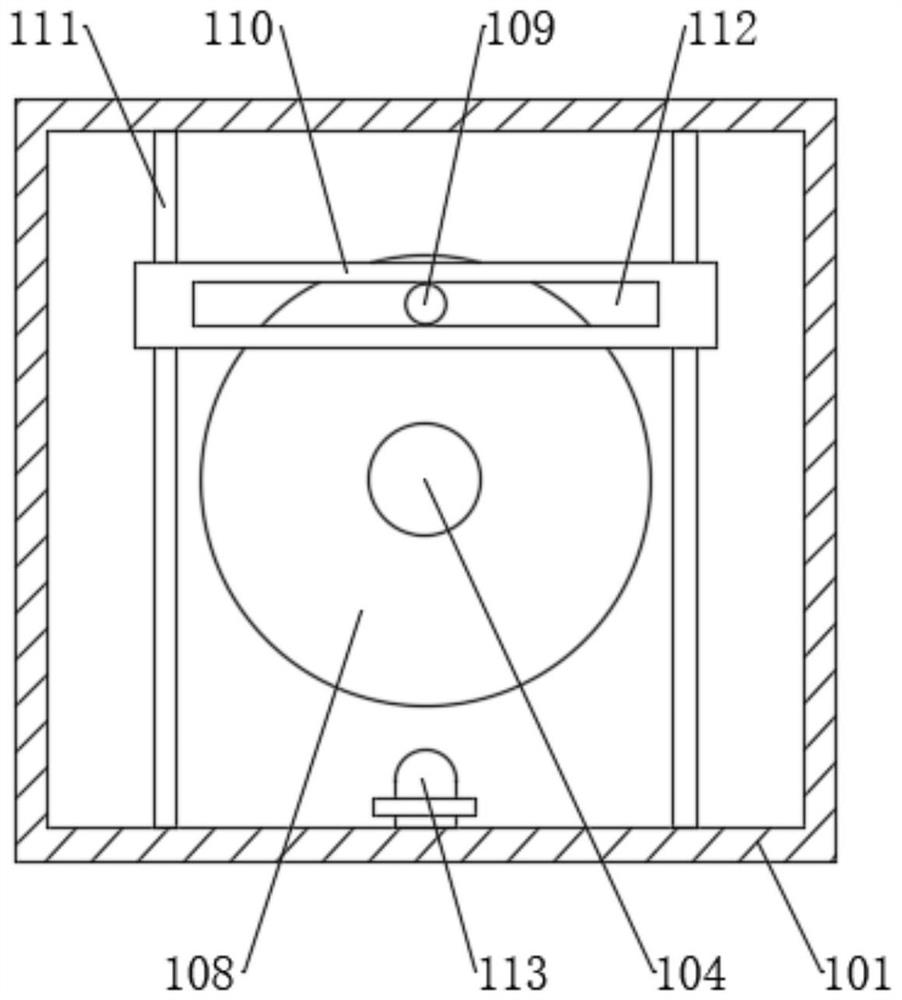

[0037] see Figure 1-3 , an intelligent numerical control tool based on wireless transmission technology, including a cutter body, the cutter body includes a clamping part cutter body 101 and a cutting part cutter body 201, a cavity is arranged in the clamping part cutter body 101, and the clamping part cutter body 101 There is an adjustment shaft 102 connected to the inside through a connecting bearing 103, the middle part of one end of the adjustment shaft 102 is fixedly connected with a linkage shaft 104, the outer wall of the linkage shaft 104 is fixed with a worm wheel 105, and the bottom inner wall of the clamping part cutter body 101 is fixed A micromotor 106 is connected, the output end of the micromotor 106 is fixedly connected with a worm 107 matching the worm wheel 105, and the worm 107 meshes with the worm wheel 105, and the end of the linkage shaft 104 away from the connecting bearing 103 is fixedly connected with an angle conversion disc 108 The angle conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com