Auxiliary cutting machine for celery stem

A cutting machine and cutting mechanism technology, applied in metal processing and other directions, can solve the problems of inaccurate control of mouth opening, time-consuming and labor-consuming, etc., and achieve the effect of simple structure, reduced manual operation, and favorable cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

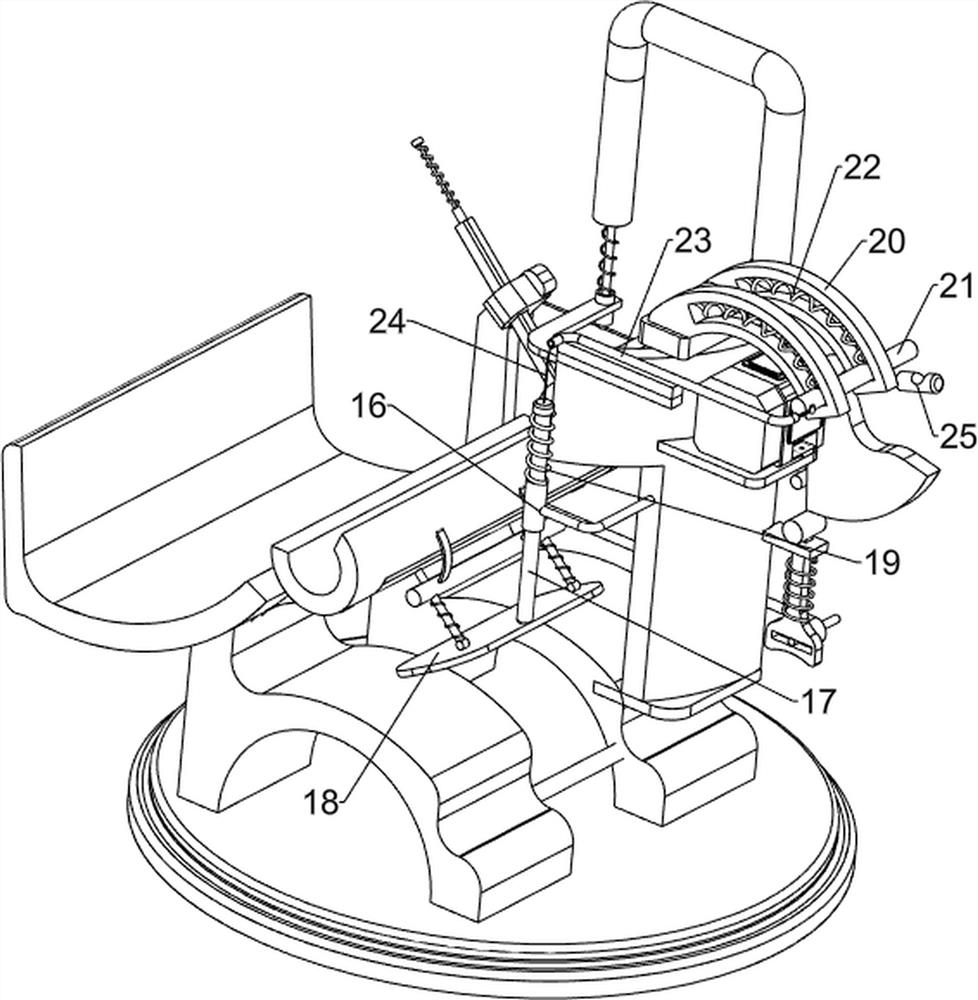

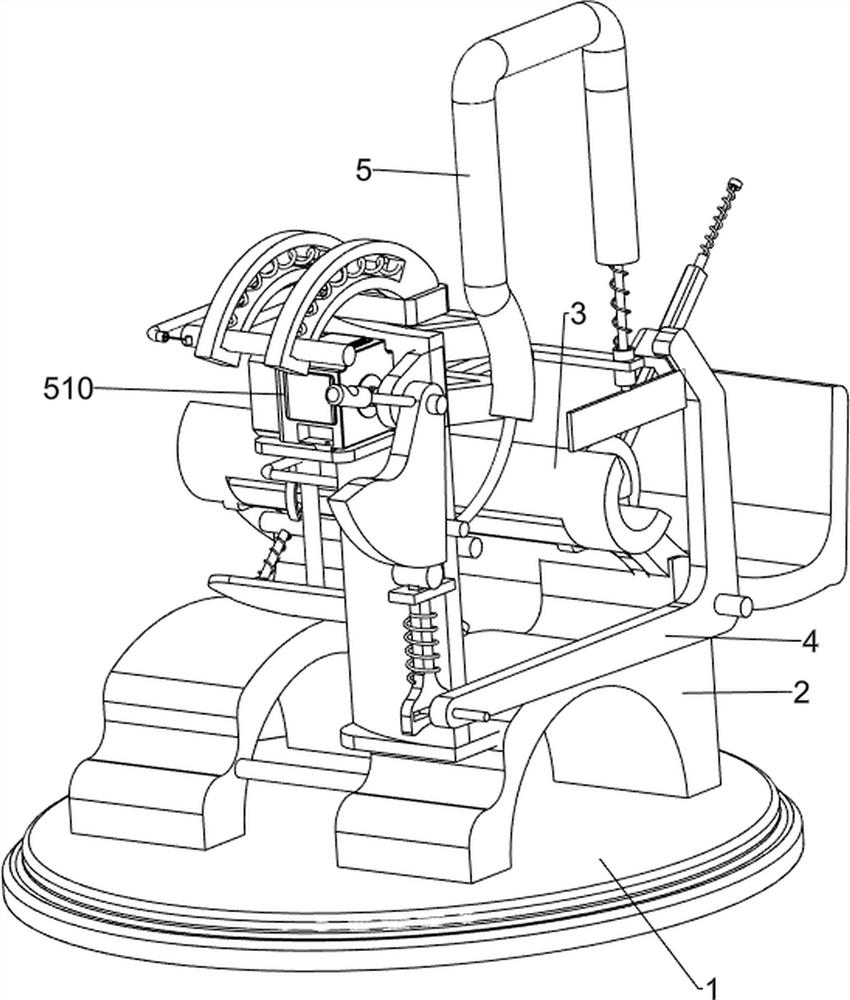

[0026] Such as figure 1 , figure 2 with image 3 As shown, a celery stalk auxiliary cutting machine includes a base 1, a workbench 2, a placement table 3, a pressing mechanism 4 and a cutting mechanism 5. The top of the base 1 is symmetrically arranged with a workbench 2, and the top of the workbench 2 is arranged There is a placing table 3, a pressing mechanism 4 is arranged on the right side wall of the right side workbench 2, and a cutting mechanism 5 is arranged on the front side wall of the right side workbench 2.

[0027] The pressing mechanism 4 includes a fixed shaft 401, a folding frame 402, a mounting block 403, a fixed rod 404 and a pressing block 405. The right side workbench 2 right side wall is provided with a fixed shaft 401. There is a folding frame 402 , the upper side wall of the folding frame 402 is provided with a mounting block 403 , the mounting block 403 is fixedly provided with a fixing rod 404 , and the bottom of the fixing rod 404 is provided with ...

Embodiment 2

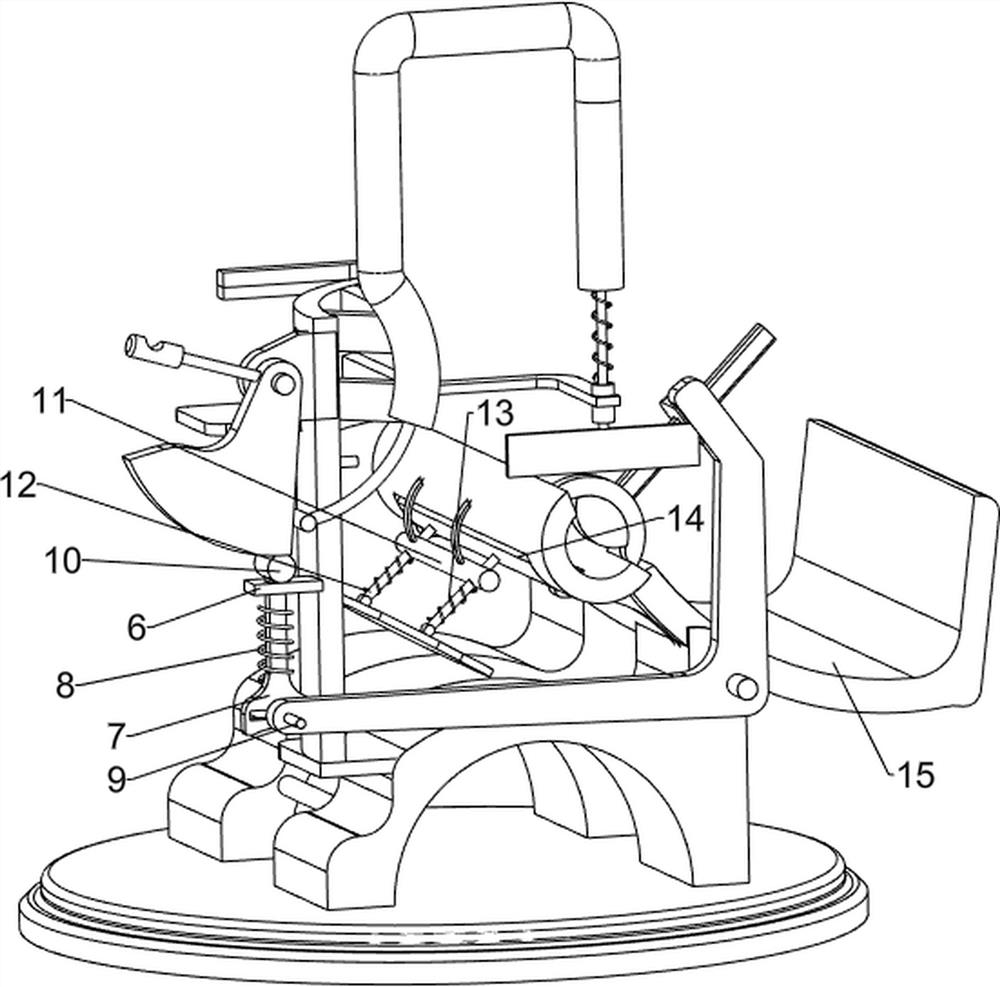

[0031] Such as Figure 4 , Figure 5 with Figure 6 As shown, on the basis of Embodiment 1, it also includes a guide block 6, a guide rod 7, a second elastic member 8, a first sliding shaft 9 and a top column 10, and the lower part of the fixed frame 501 is provided with a guide block 6, and the guide A guide rod 7 is slidably arranged in the block 6, and a groove is opened at the bottom of the guide rod 7. A second elastic member 8 is connected between the guide rod 7 and the guide block 6. The front end of the folding frame 402 is provided with a first slide shaft 9. , the first sliding shaft 9 is slidingly matched with the slot of the guide rod 7, and the top of the guide rod 7 is provided with a push post 10, and the push post 10 cooperates with the arc surface of the special-shaped top block 509.

[0032]The staff controls the servo motor 510 to drive the special-shaped top block 509 to rotate counterclockwise. The curved top block 509 first squeezes the top column 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com