Auxiliary fixing device for carbon fiber sheet laying of railway vehicle body

A technology for a rail vehicle and a fixing device is applied in the field of auxiliary positioning devices for carbon fiber sheet paving, which can solve the problems of inability to guarantee normal lines, inability to guarantee the quality and efficiency of paving and riveting operations, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below with reference to the accompanying drawings.

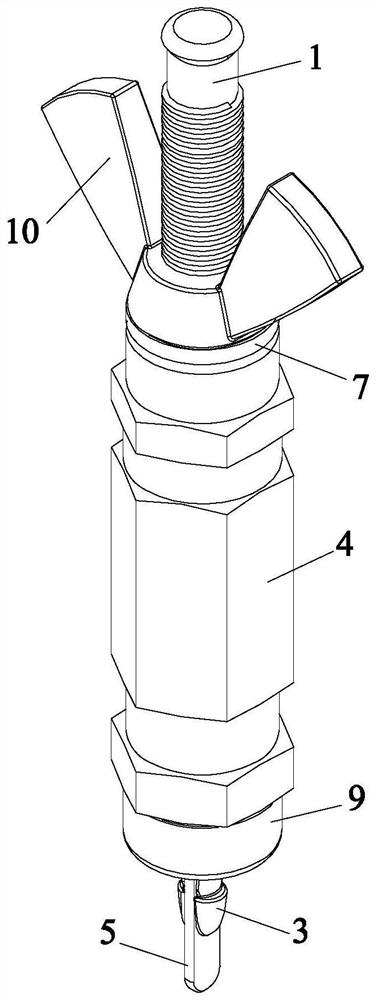

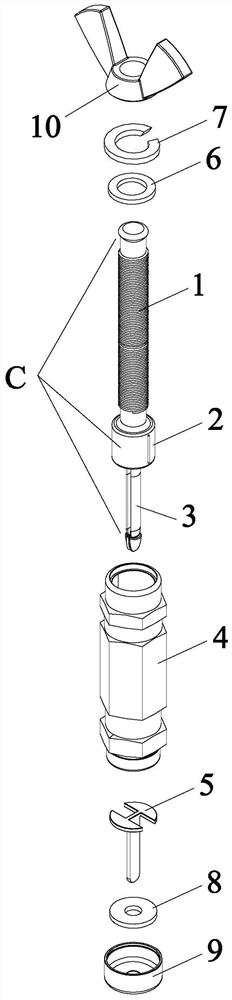

[0041] like Figures 2 to 11 As shown, the rail vehicle body carbon fiber sheet of the present invention includes auxiliary fixture including a screw 1, a guide slider 2, two single spring semi-cone 3, sleeve 4, a bullion, a sleeve end? The cover 6, the spring sheet 7, the casing 8, the sleeve front end cover 9 and the dove-tail nut 10, the screw 1 and the two-shelled cone 3 coaxial stepping on the front, rear end surface of the guide slider 2, Thin, together, form a whole cone positioning push rod C.

[0042] like Figure 5 As shown, the single spring semicircular cone 3 includes a sequential and integrally formed reed straight rod 3-1, a variable diameter elbow 3-2, and a semi-cone 3-3, two single spring sheets The cone 3 mirror symmetrical symmetry and arranges parallel and together forms a double spring cone mechanism D.

[0043] like Image 6 As shown, the bulk t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com