High-voltage direct-current polypropylene cable material

A high-voltage DC, polypropylene technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problem of poor low-temperature performance and cannot be widely used, achieve excellent mechanical properties and electrical properties, reduce use costs, and environment. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

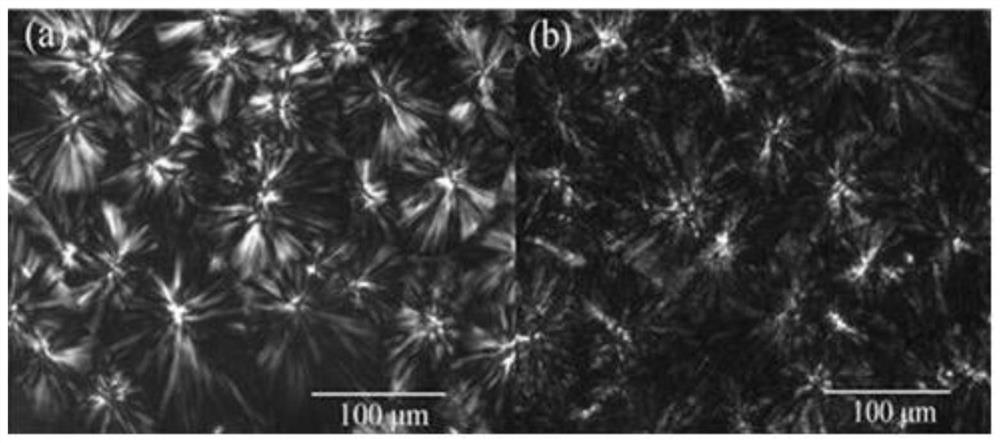

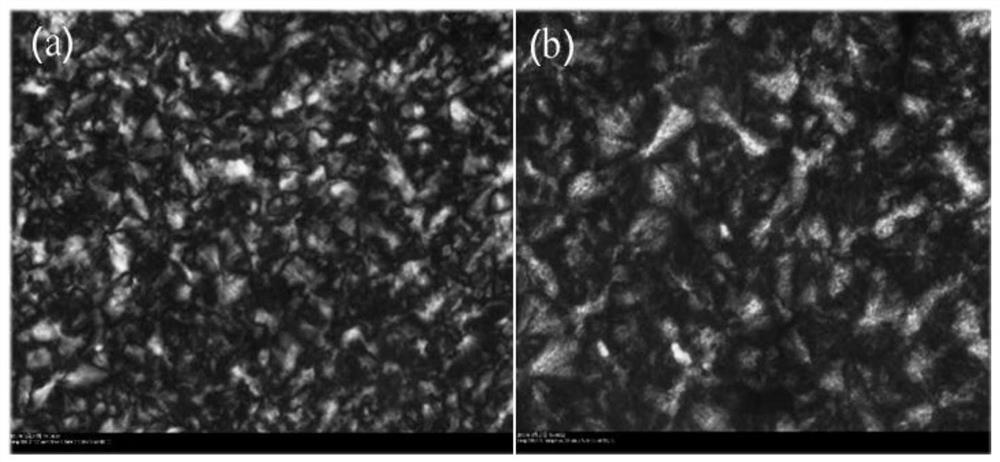

Image

Examples

Embodiment 1

[0028] Take 100 parts of isotactic copolymerized polypropylene obtained by modifying isotactic polypropylene, 0.8 parts of 1,2-bis(3,5-di-tert-butyl-4-hydroxy-phenylpropionic acid)hydrazine and 0.15 parts of four [ β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester is added to a granulation device and directly granulated to obtain polypropylene cable material.

Embodiment 2

[0030] Take 100 parts of random polypropylene modified by random polypropylene, 0.6 parts of 1,2-bis(3,5-di-tert-butyl-4-hydroxy-phenylpropionic acid) hydrazine, 0.1 part of four [ β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, 0.1 part of tris(2,4-di-tert-butylphenyl)phosphite and 0.1 part of 4,4'-thio Add bis(6-tert-butyl-3-methylphenol) into the granulation device and directly granulate to obtain polypropylene cable material.

Embodiment 3

[0032] Take 100 parts of isotactic copolymerized polypropylene obtained by modifying isotactic polypropylene, 0.4 parts of 1,2-bis(3,5-di-tert-butyl-4-hydroxy-phenylpropionic acid) hydrazine and 0.1 part of four [ β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester is added to a granulation device and directly granulated to obtain polypropylene cable material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com