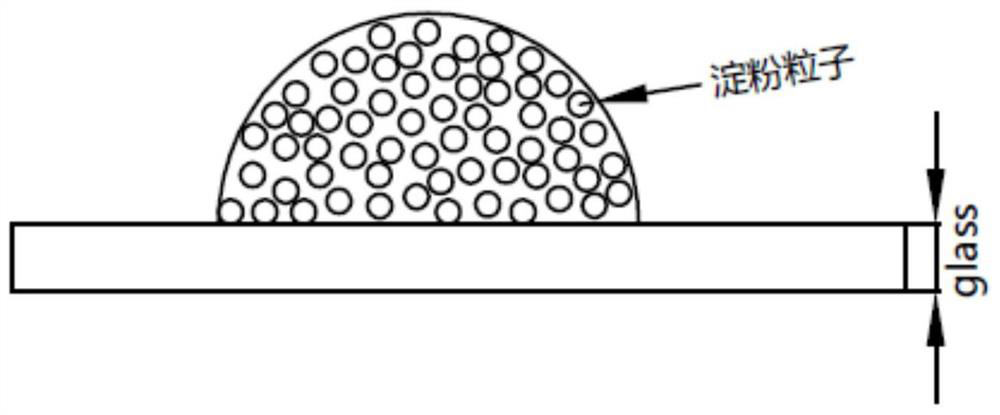

Starch modified UV adhesive and preparation method thereof

A starch modification and adhesive technology, applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve problems such as leaving scratches, easily damaged substrates, failure to disassemble, etc., and achieve good Cohesiveness, avoiding oxygen inhibition, and improving cohesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

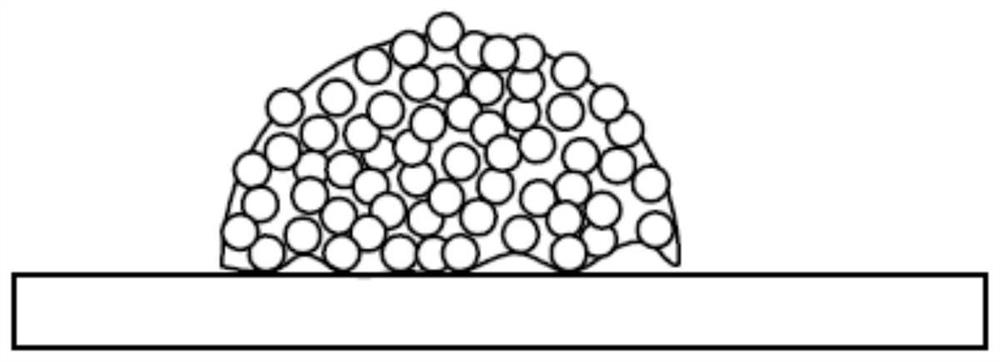

Method used

Image

Examples

preparation example Construction

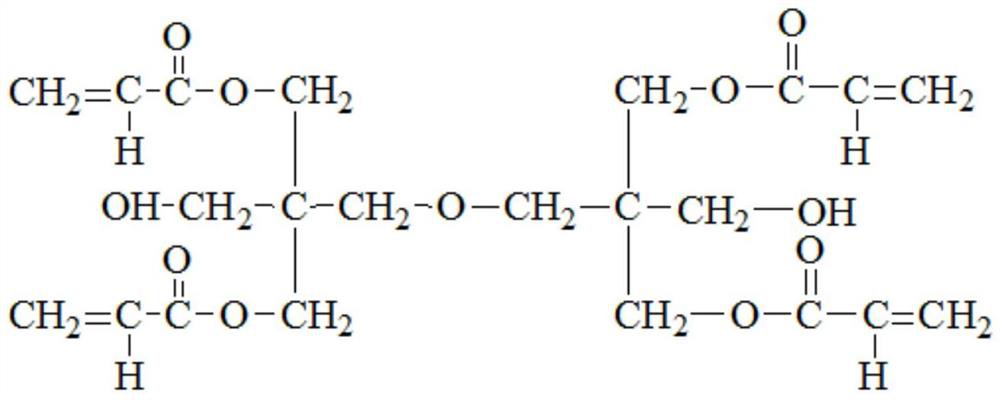

[0028] Also provided here is the preparation method of the UV adhesive of above-mentioned starch modification, comprises the following steps:

[0029] 1) Under the yellow light, add acrylic polyester A, acrylic polyester B and photoinitiator into the reaction kettle and heat up to 50°C, and stir until the photoinitiator is completely dissolved;

[0030] 2) Under the yellow light, after cooling down to room temperature, add mercaptan, coupling agent, fumed silica, and finally starch, and stir at room temperature until completely mixed;

[0031] 3) Under the yellow light, grind the fully mixed material through a three-roll mill until the particle size is less than 15um;

[0032] 4) Under the yellow light, after discharging, it should be sealed and protected from light after filling and vacuum defoaming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com