Cold-rolled high-strength steel with good coating quality and preparation method thereof

A high-strength steel, high-quality technology, applied in the coating process of metal materials, etc., can solve the problems of inability to form phosphating film, difficulty in surface phosphating, and poor quality of electrophoretic film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

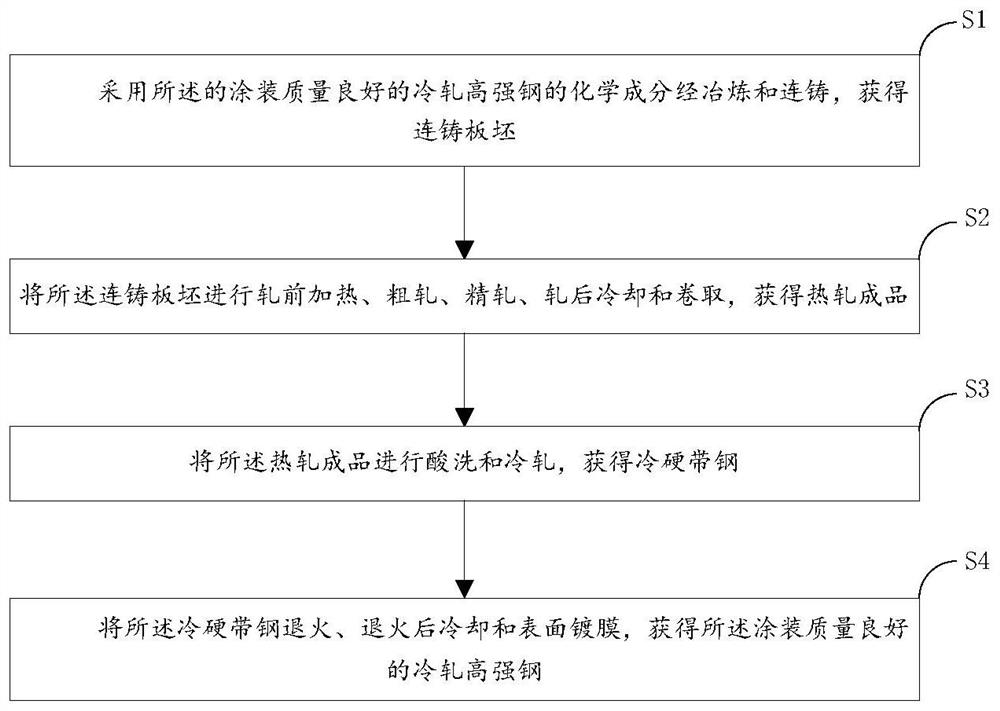

[0045] According to a typical implementation of the embodiment of the present invention, a method for preparing cold-rolled high-strength steel with good coating quality is provided, such as image 3 As shown, the method includes:

[0046] S1, using the chemical composition of the cold-rolled high-strength steel with good coating quality to obtain continuous casting slabs through smelting and continuous casting;

[0047] S2. Heating the continuous casting slab before rolling, rough rolling, finish rolling, cooling after rolling and coiling to obtain a hot-rolled finished product;

[0048] The temperature of the pre-rolling heating is 1235°C-1285°C, and the time of the pre-rolling heating is ≥180min. If the heating temperature before rolling is too low, it will affect the plasticity, if it is too high, it will easily affect the surface quality;

[0049] The finish rolling temperature of the finish rolling is 900°C to 1100°C. If the final rolling temperature is too low, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com