High-strength deformation-resistant carbon fiber bulletproof composite plate and forming process thereof

A forming process, technology of carbon fiber plate, applied in the structure of armor plate, lamination device, lamination, etc., can solve the problems of carbon fiber bulletproof composite plate processing and forming, and achieve good hot pressing forming, high production and processing efficiency, and convenience The effect of fast loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

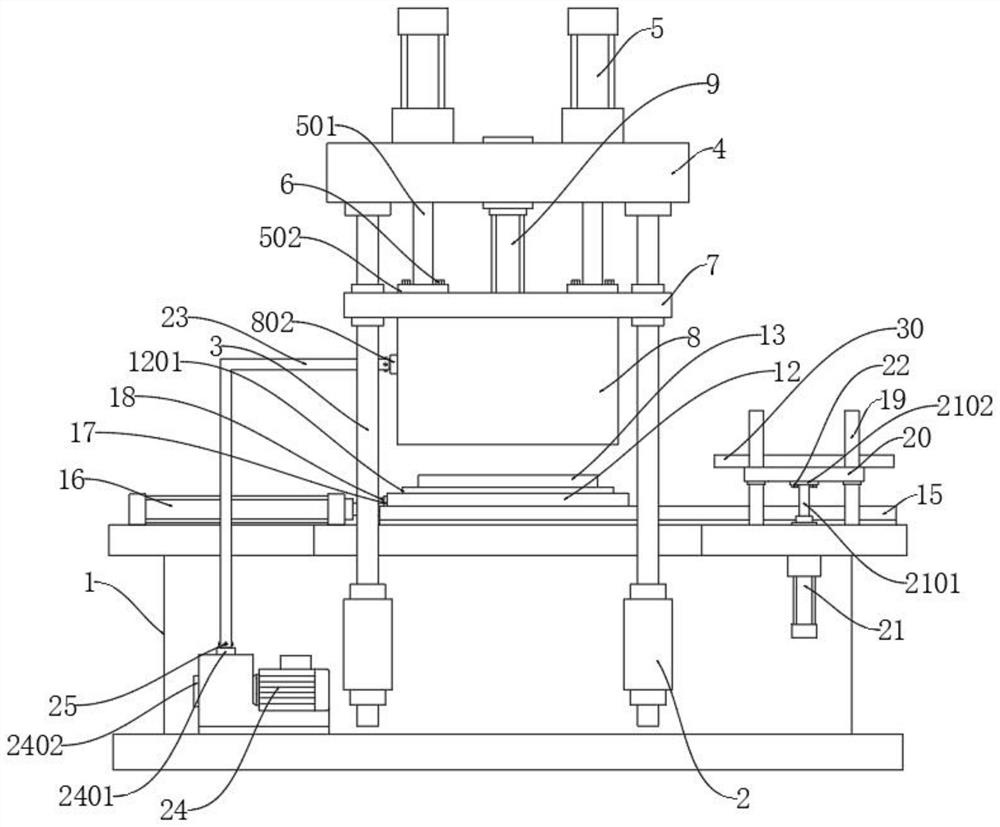

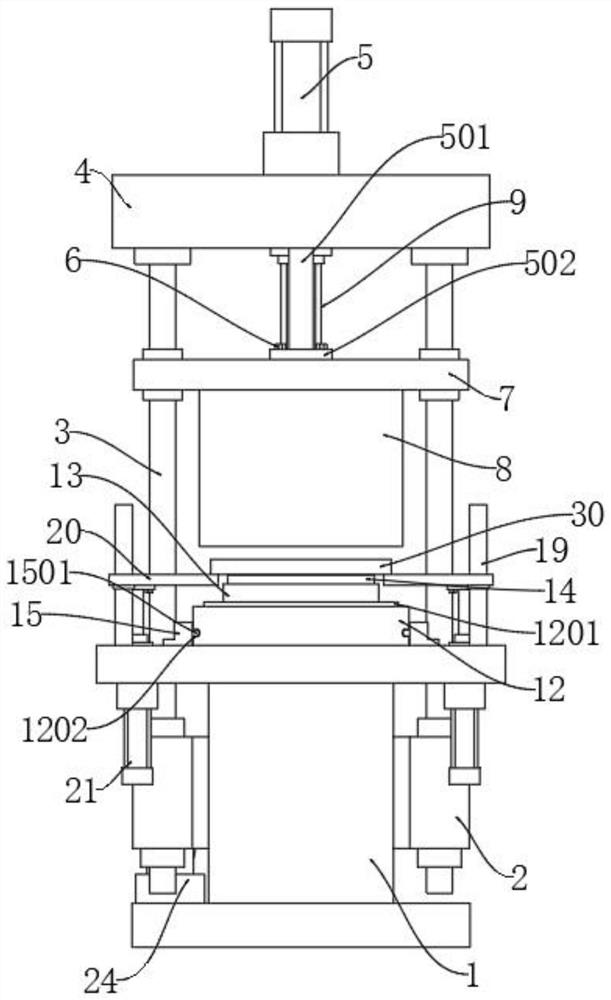

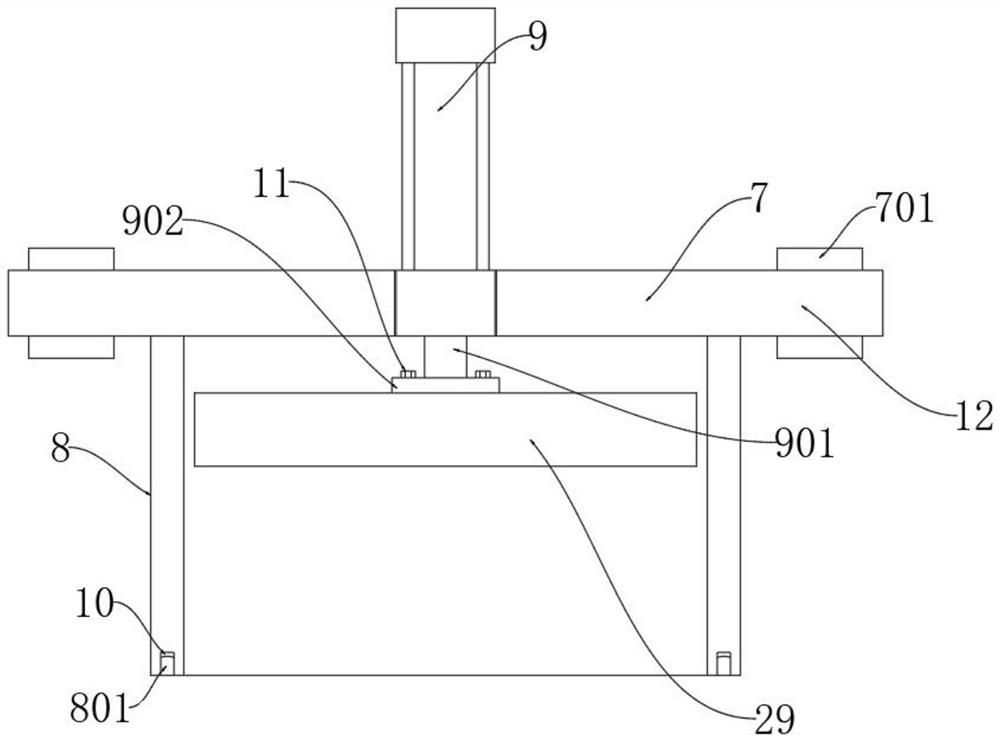

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0032] see Figure 1-7 , an embodiment provided by the present invention: a forming process of a high-strength anti-deformation carbon fiber bulletproof composite plate, comprising the following steps:

[0033] Step 1: By opening the push cylinder 16, the connecting plate 17 pushes the mobile support seat 12 to move along the direction of the limit slide 15, so that the mobile support seat 12 moves to the position directly below the upper extrusion seat 30, and then passes Control pushes cylinder 16 to stop working;

[0034] Step 2: Place the epoxy resin 1401, carbon fiber board 1402, and polyethylene reinforcement board 1403 on the top of the mobile support seat 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com