A pre-flight self-inspection method and self-inspection system of a fiber optic gyroscope with high coverage

A technology of fiber optic gyroscope and coverage rate, which is applied in the direction of Sagnac effect gyroscope, instrument, power supply test, etc., can solve the problem of low coverage rate, achieve high data accuracy, avoid attitude loss control, and ensure voltage stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings. Apparently, the described embodiments do not limit the present invention.

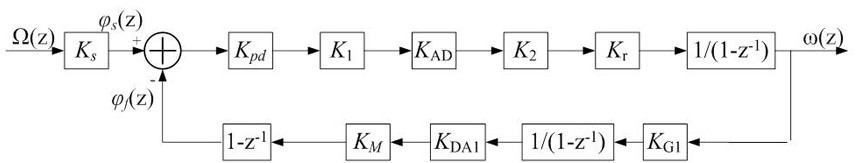

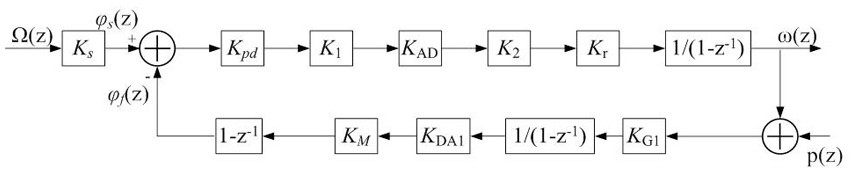

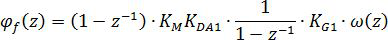

[0045] The invention provides a self-inspection method before flight with a high coverage rate of an optical fiber gyroscope. Through the means of self-inspection with a high coverage rate, the fault status of the function and performance of an optical fiber gyroscope can be accurately judged before flight, and the failure of the air carrier system failure is minimized. Probability, avoiding the loss of attitude control, and ensuring the carrier to perform safe and reliable flight missions. Realize the self-inspection of all functions and performances of the optical path and circuit of the fiber optic gyroscope, give quantitative test results, and greatly improve the self-inspection ability of the closed-loop fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com