Sintered ore FeO content on-line detection device and method with inclined sleeve structure

A detection device and sintered ore technology, which is applied in the direction of measuring devices, weighing, and material magnetic variables, can solve the problems of reduced life of the magnetic induction coil and skeleton, the diameter of the magnetic induction coil cannot be too large, and affect the use of the device, so as to reduce maintenance. Quantity and operating costs, reduce labor intensity, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

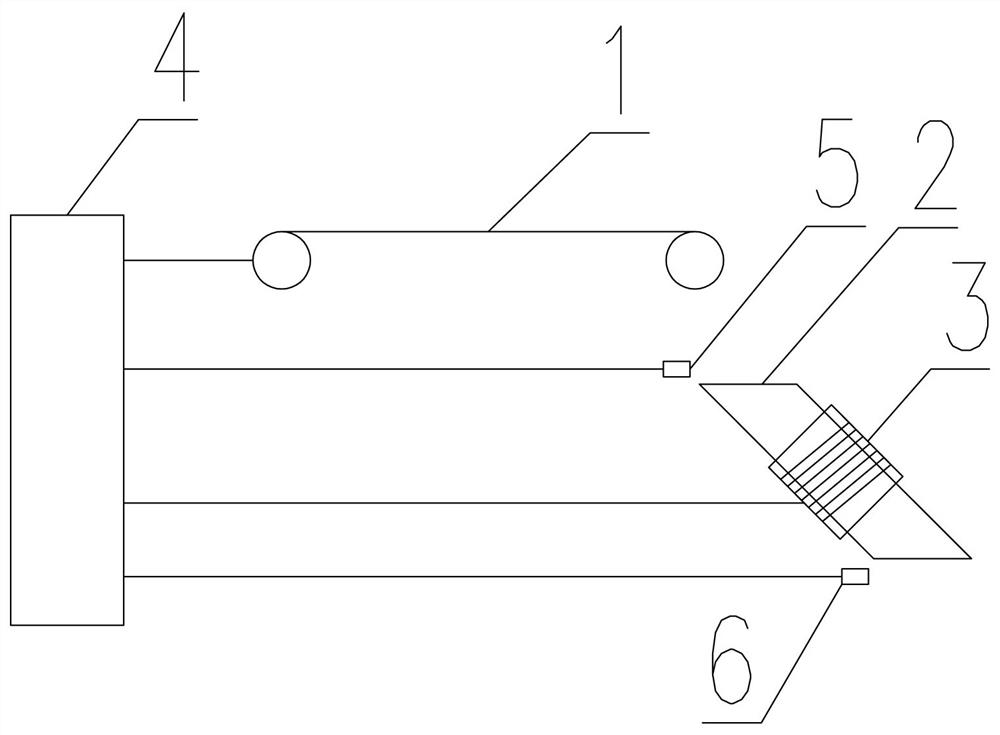

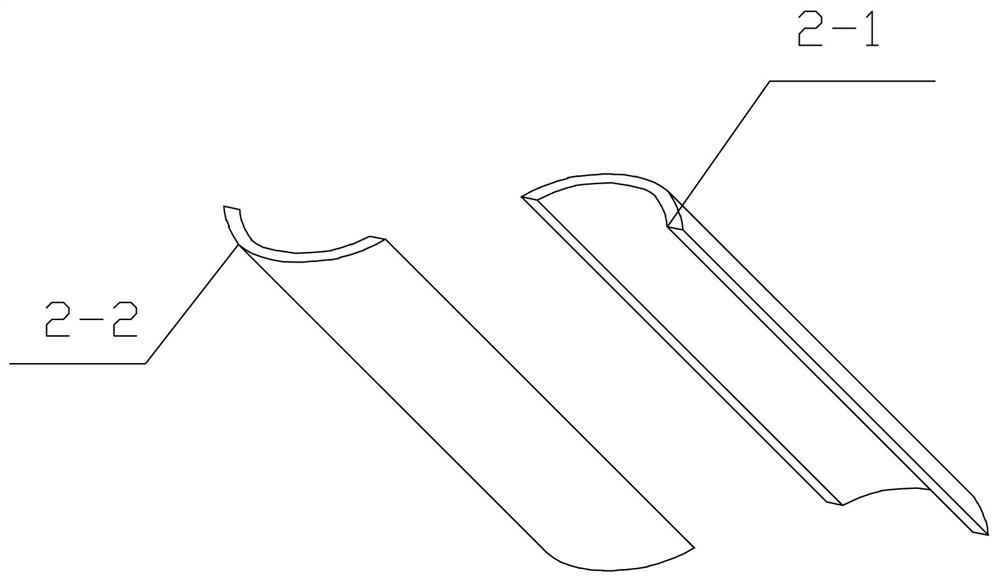

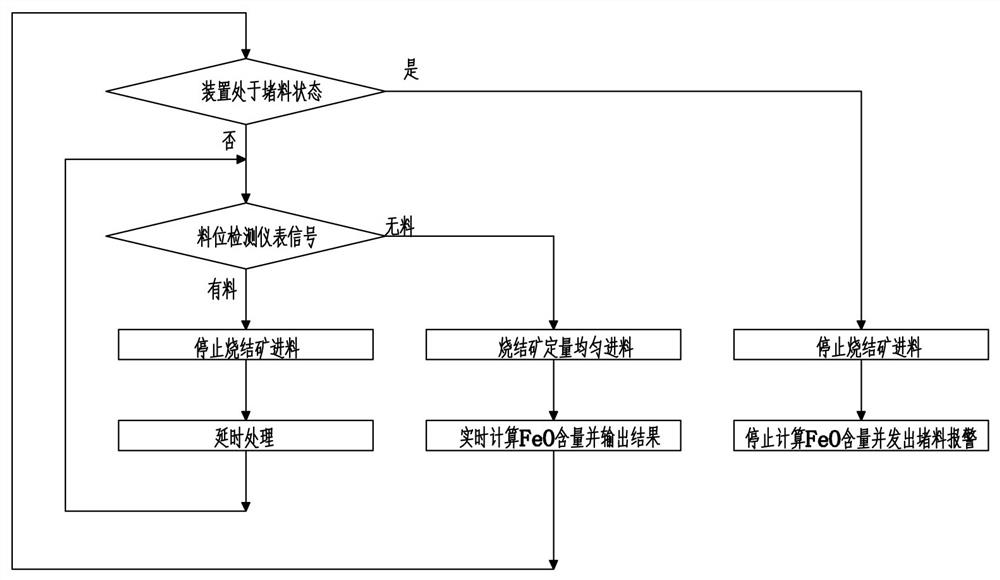

[0035] Such as figure 1 , 2 As shown, an on-line detection device for FeO content of sintered ore with an inclined sleeve structure of the present invention includes a feed batching scale 1 , a feeding inclined chute 2 , a magnetic induction coil 3 and its skeleton, and an electric control system 4 . The feed batching scale 1 can control the amount of sinter feed in the feeding inclined chute 2 by adjusting the operating speed; the feeding inclined chute 2 is located below the feeding point of the feeding batching scale 1, and the feeding inclined chute 2. The upper part is a slanted cylindrical cylinder. Furthermore, the inclined chute includes No. 1 chute 2-1 and No. 2 chute 2-2 for buckling correspondingly with No. 1 chute 2-1. No. 1 chute 2-1 and No. 2 chute 2-2 vertically divide the inclined chute into equal parts; the magnetic induction coil 3 and its skeleton are lubricated and installed on the outer wall of the middle part of the inclined chute 2 with a sleeve structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com