Quartz flexible accelerometer based on miniature torquer and manufacturing method thereof

A technology of accelerometer and torquer, which is applied in the field of quartz flexible accelerometer and its manufacturing, can solve the problems of inability to achieve micro-nano process compatibility and temperature drift, and achieve the effect of promoting high precision and suppressing temperature drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

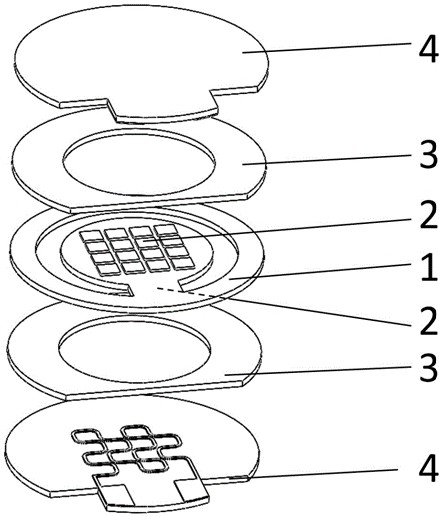

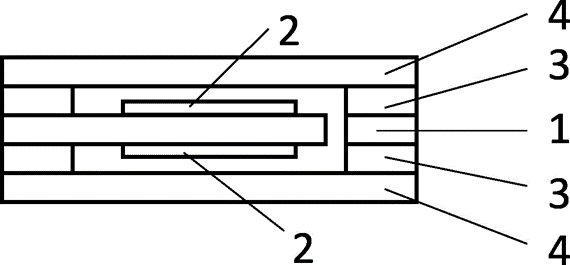

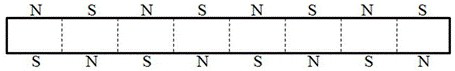

[0039] Such as Figure 1-Figure 2 As shown, the quartz flexible accelerometer based on the microtorque device of the present invention includes a quartz flexible pendulum 1, and the upper and lower sides of the quartz flexible pendulum 1 are sequentially placed with a permanent magnetic film 2, a capacitor plate 3 and a silicon substrate. Coil 4, so that the quartz flexible accelerometer is a push-pull structure with the quartz flexible pendulum 1 as the center of symmetry and symmetrical up and down sides, and the whole accelerometer is in a flat shape;

[0040] Wherein, the capacitor pole plate 3 is a silicon wafer with a single-side vapor-deposited Au metal layer, the thickness of the silicon wafer is not less than the thickness of the permanent magnetic film 2, and a hollowed out part is set in the center of the silicon wafer, and the radi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radial size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com