Plate counting system and method based on machine vision

A technology of machine vision and counting method, applied in counting mechanisms/items, instruments, calculations, etc., can solve problems such as poor applicability and low detection accuracy, and achieve the goal of improving the degree of automation, ensuring accuracy, and reducing labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

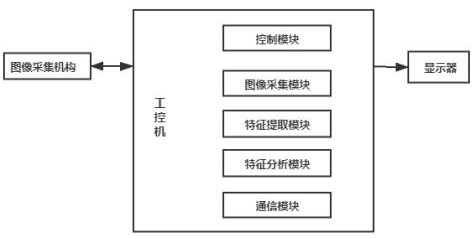

[0049] figure 1 As shown, a plate counting method based on machine vision, including image acquisition mechanism, industrial computer and display.

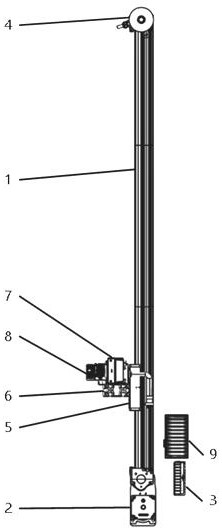

[0050] figure 2 As shown, the main body of the image acquisition mechanism is the electric slide rail 1 and the motor 2 of the slide rail, the encoder 4 is installed at the end of the slide rail, the camera 7, the lens 8 are installed and the light source is on the bracket 6, and the bracket 6 is installed on the slide table 5 On, the whole camera part can follow the slide table to move. The motor controller 3 and the light source controller 9 are installed in other positions to connect with the motor and the light source respectively.

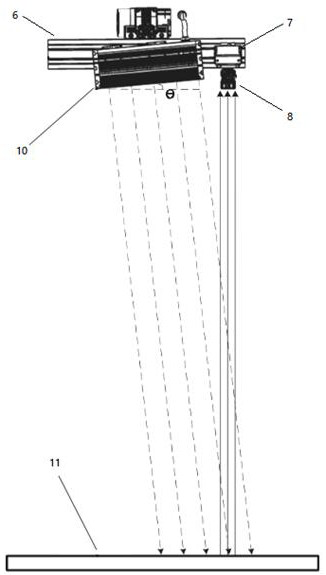

[0051] image 3 As shown, the camera 7 and the lens 8 in the top view of the sliding table are installed on the bracket 6, and the light source 10 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com