A heat dissipation communication repeater

A repeater and heat-dissipating technology, which is applied in the field of heat-dissipating communication repeaters, can solve the problems of increasing the temperature of communication repeater equipment, unfavorable conversion operations, signal distortion, etc., and achieve the effect of ensuring work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

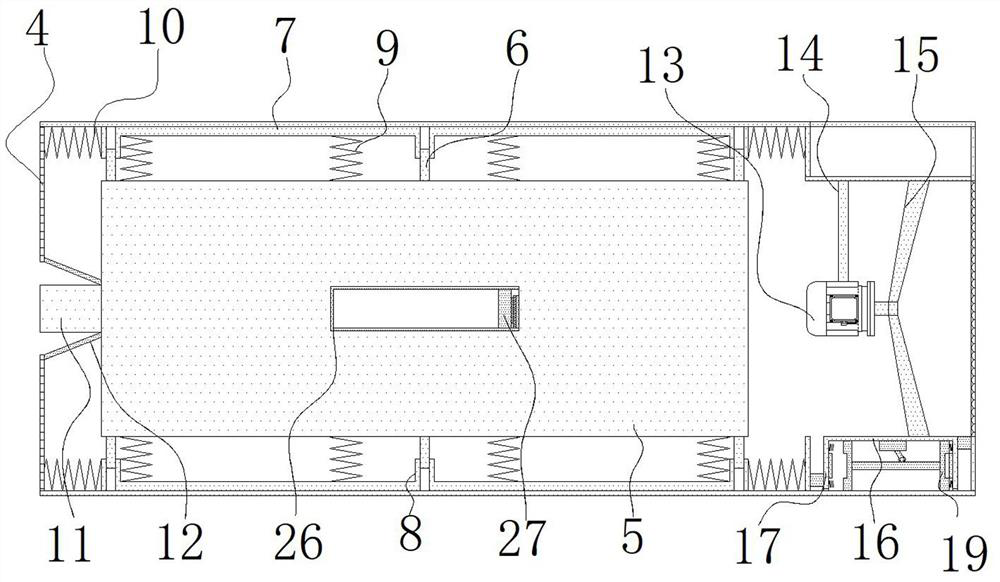

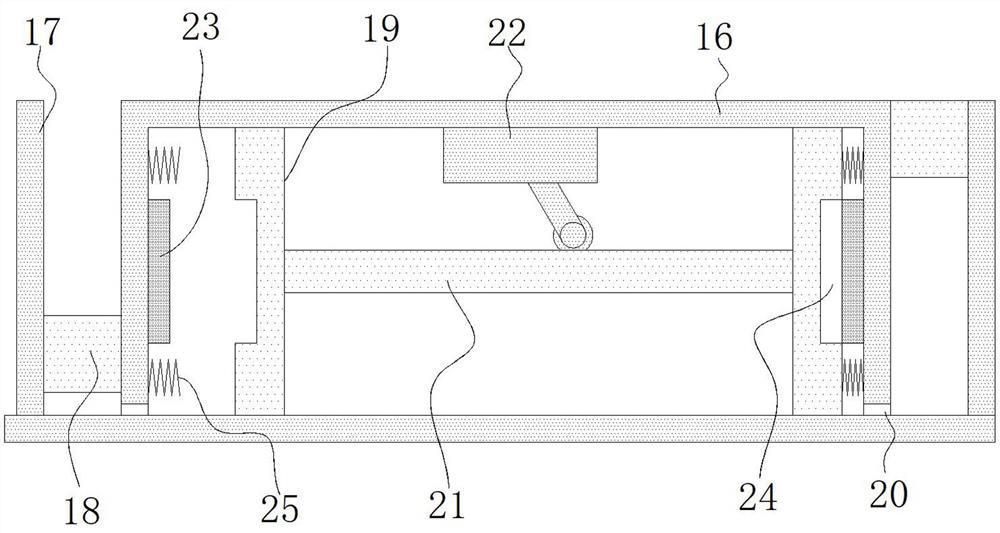

[0025] As a preferred embodiment of the present invention, the touch switch 28 is connected to the bidirectional switch 22 through wires, and the bidirectional switch 22 is connected to the motor 13 through wires.

[0026]As a preferred embodiment of the present invention, the motor 13 is installed on the inside of the hood 1 through the strut 14, and the fan blade 15 is installed on the output shaft of the motor 13 through bolts, and can be opened when the touch switch 28 Finally, the motor 13 drives the fan blade 15 to rotate, and then utilizes the fan blade 15 to fan the air flow, so that the outside air enters the hood 1 after being filtered by the filter screen 3 or the filter plate 4, and takes away the repeater 5 After absorbing the heat generated by the work, it flows out through the filter plate 4 or the filter screen 3, thereby effectively cooling the repeater 5 and ensuring the working safety of the repeater 5.

[0027] As a preferred embodiment of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com