Polyimide film having excellent yield strain and flexural characteristics

A polyimide film, yield strain technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of low chemical resistance and mechanical strength, difficult to apply flexible displays, and the overall thickness of the outer covering window changes, etc. Achieve low yellowness, improved handling and reliability, excellent modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0077] [Examples 1 to 5. Production of polyimide film]

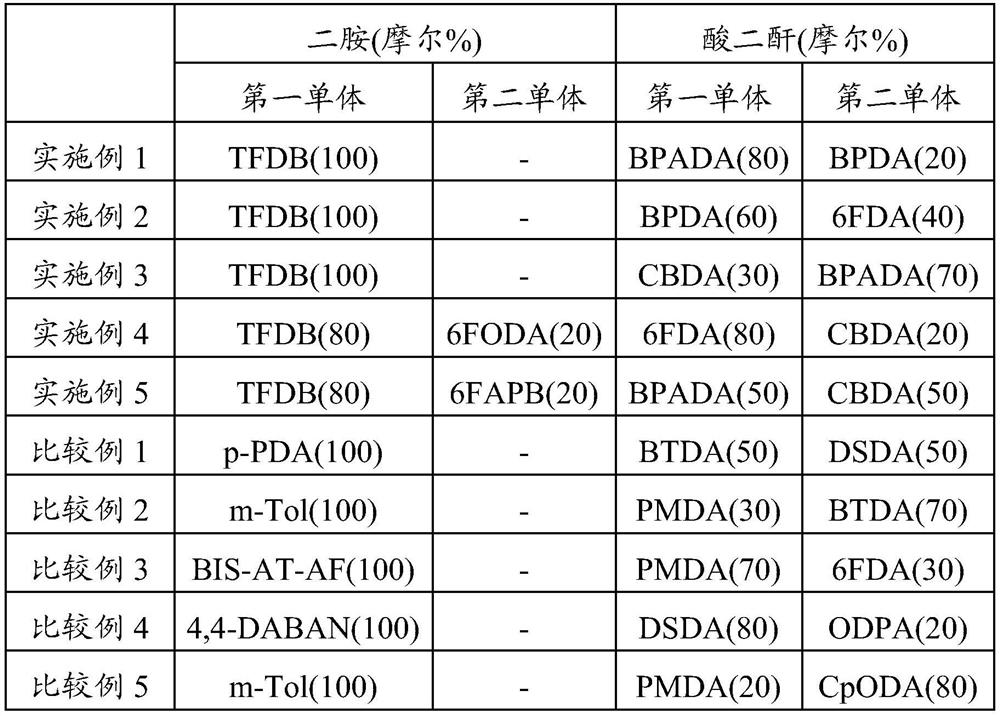

[0078] The polyamic acid composition was manufactured using the composition containing the diamine and acid dianhydride described in Table 1 below.

[0079] After coating the above polyamic acid composition on a glass plate for LCD with a bar coater (Bar Coater), it was carried out in a convection oven in a nitrogen atmosphere at 80°C for 30 minutes, at 150°C for 30 minutes, and at 200°C. Drying and imide ring closure reaction (Imidazation) were performed simultaneously by gradually raising the temperature step by step at 300° C. for 1 hour. Thus, a polyimide film having a film thickness of 80 μm with an imidization rate of 85% or more was produced. After that, the polyimide film was separated from the glass plate and obtained.

[0080] [Table 1]

[0081]

experiment example

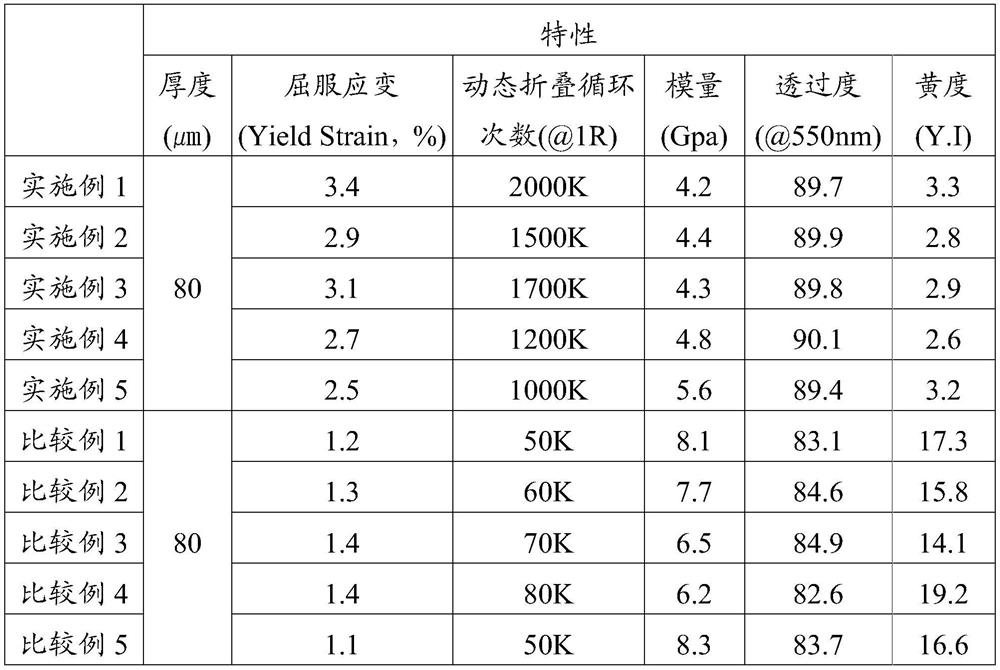

[0084] [Experimental example. Evaluation of physical properties]

[0085] The physical properties of the polyimide resin films produced in Examples 1 to 5 and Comparative Examples 1 to 5 were evaluated by the following methods, and the results are shown in Table 2 below. At this time, the physical properties in Table 2 below were evaluated on the basis of a thickness of 80 μm.

[0086]

[0087] 1) Transmittance measurement

[0088] Measurement was performed at a wavelength of 550 nm using a UV-Vis NIR Spectrophotometer (UV-Vis NIR Spectrophotometer, Shimadzu, model name: UV-3150).

[0089] 2) Determination of yellowness

[0090] The yellowness at 550 nm was measured using a spectrophotometer (Konica Minolta, CM-3600A) according to ASTM E313-73 standard.

[0091] 3) Thickness measurement

[0092] The thickness of the film was measured with a thickness meter (Mitutoyo, model name: 547-401).

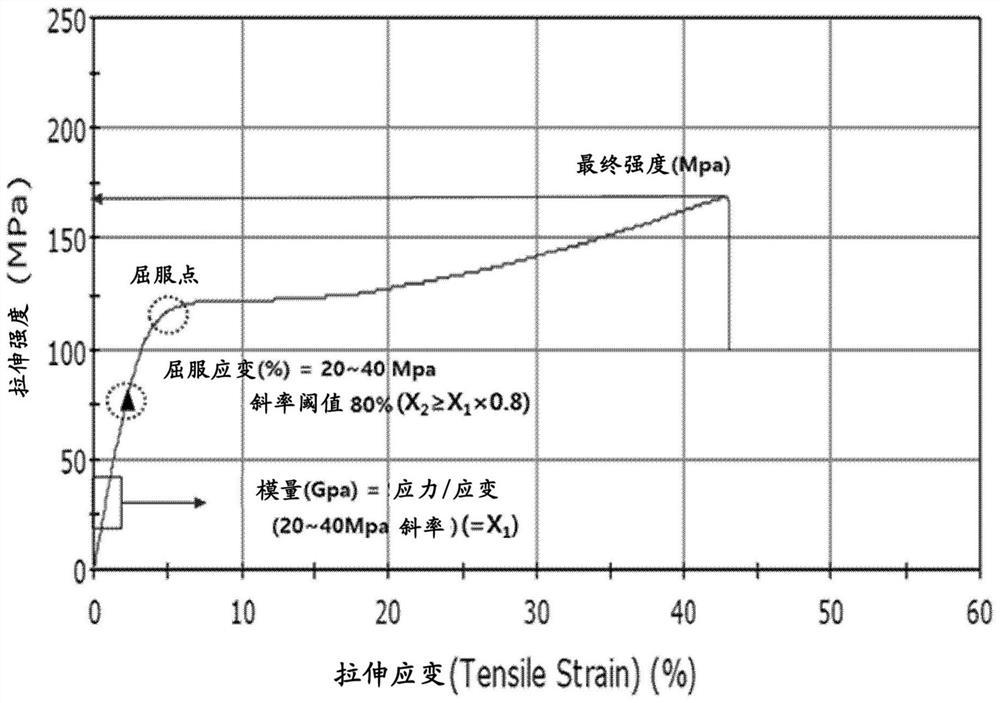

[0093] 4) Modulus measurement

[0094] UTM (Instron, model name: 5942) was used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com