Method for extracting soil nano colloid

A nano-colloid and soil technology, applied in the field of soil chemistry, can solve problems such as insufficient operating conditions, long extraction time, and low extraction volume, and achieve the effects of ensuring parallelism and accuracy, reducing sample loss, and shortening extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The embodiment of the present invention selects yellow soil, collected from a paddy field in Anqing, Anhui.

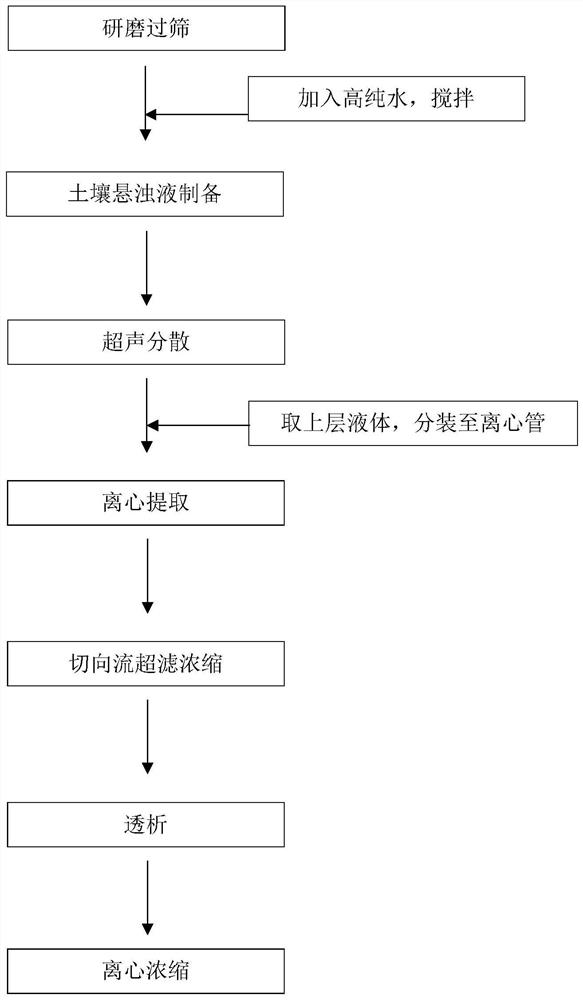

[0036] (1) Air-dry the collected soil naturally, remove gravel, gravel and plant roots, etc., grind through a 10-mesh sieve, and mix the soil evenly after sieving.

[0037] (2) Take 50 g of the above uniformly mixed soil, add 1 L of ultrapure water and stir with a glass rod for 5-10 min to obtain a soil suspension.

[0038] (3) Ultrasonic disperse the soil suspension for 1 hour, and transfer the upper layer liquid into a 50ml centrifuge tube.

[0039] (4) Centrifuge the components transferred into the centrifuge tube, calculate according to the Stokes formula, set the centrifugation speed to 6030 rpm / min, centrifuge temperature at 4°C, centrifuge for 20 min, centrifuge three times in total, and take the supernatant each time solution to obtain a soil nanocolloid suspension.

[0040] (5) Concentrate 600mL of soil nanocolloid suspension by tangential flow ultraf...

Embodiment 2

[0044] The embodiment of the present invention selects brown soil, which is collected from a paddy field in Xinxiang, Henan.

[0045] (1) Air-dry the collected soil naturally, remove gravel, gravel and plant roots, etc., grind through a 10-mesh sieve, and mix the soil evenly after sieving.

[0046] (2) Take 50 g of the above uniformly mixed soil, add 1 L of ultrapure water and stir with a glass rod for 5-10 min to obtain a soil suspension.

[0047] (3) Ultrasonic disperse the soil suspension for 1 hour, and transfer the upper layer liquid into a 50ml centrifuge tube.

[0048] (4) Centrifuge the components transferred into the centrifuge tube, calculate according to the Stokes formula, set the centrifugation speed to 6030 rpm / min, centrifuge temperature at 4°C, centrifuge for 20 min, centrifuge three times in total, and take the supernatant each time solution to obtain a soil nanocolloid suspension.

[0049] (5) Concentrate 600mL of soil nanocolloid suspension by tangential f...

PUM

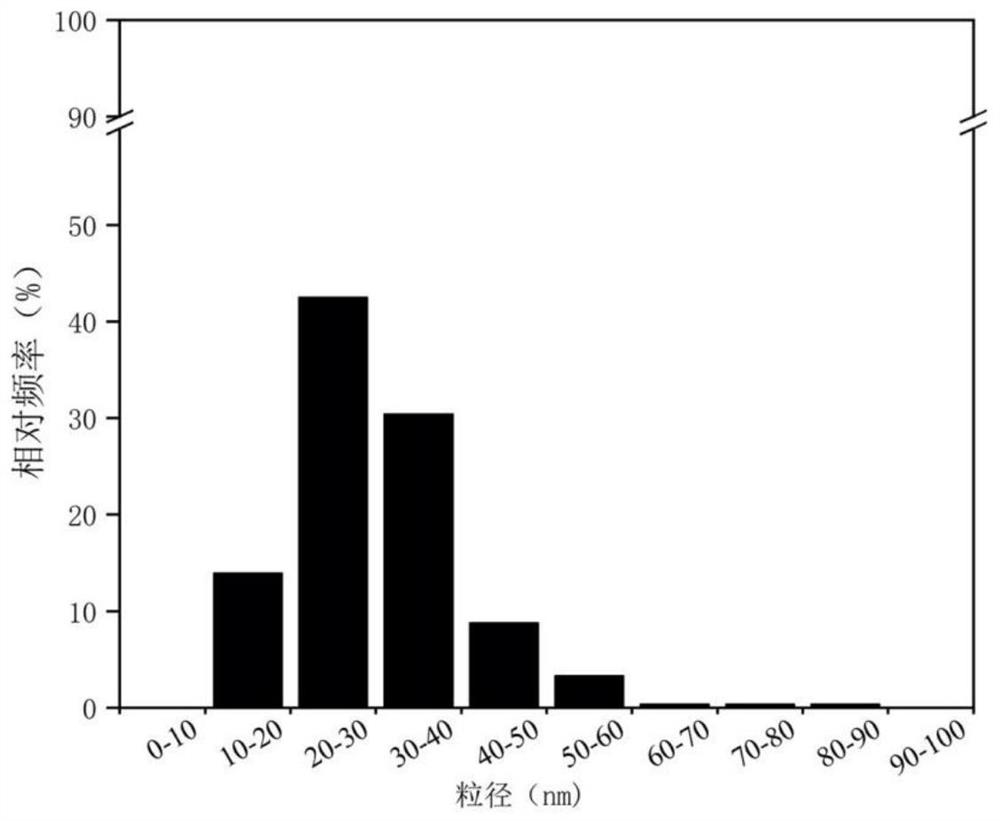

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com