Angle detection device for cutting surface of silicon single crystal rod

A technology of angle detection and monocrystalline silicon rods, which is applied in the direction of fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of lack of automatic correction devices for detection devices, inability to automatically clamp and affect production efficiency, etc., to achieve Simple and reasonable structure, convenient measurement and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

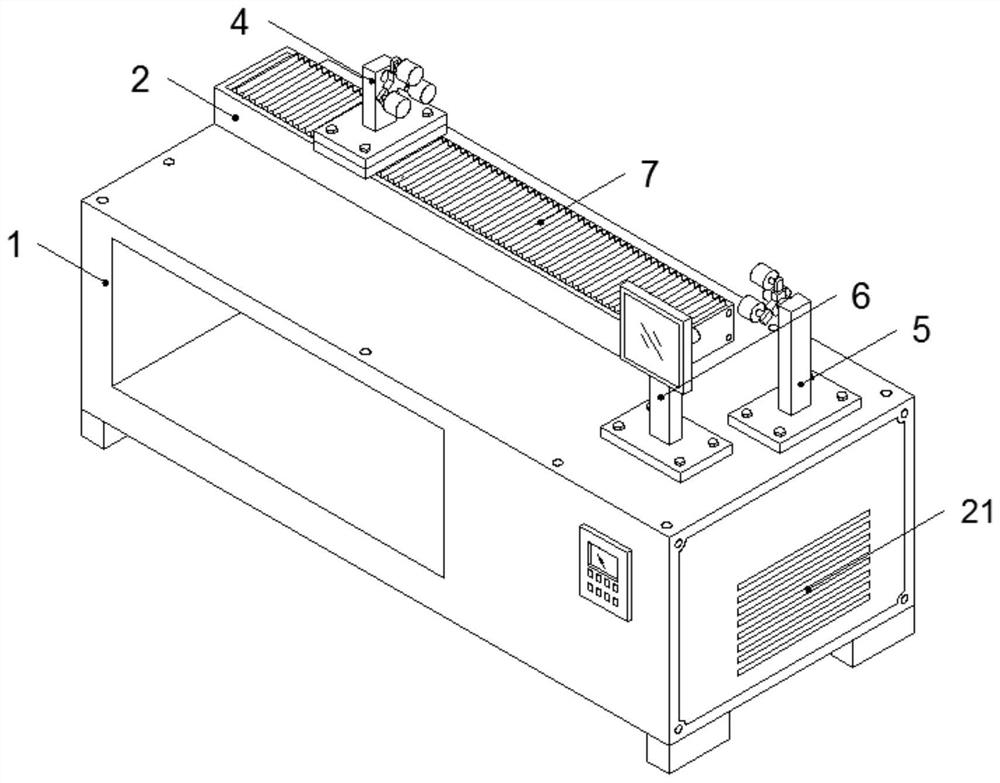

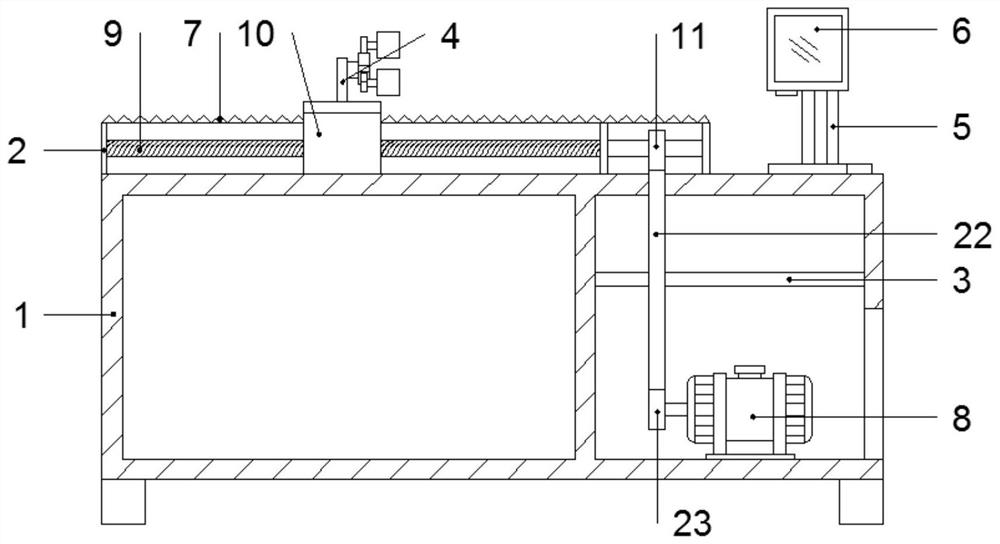

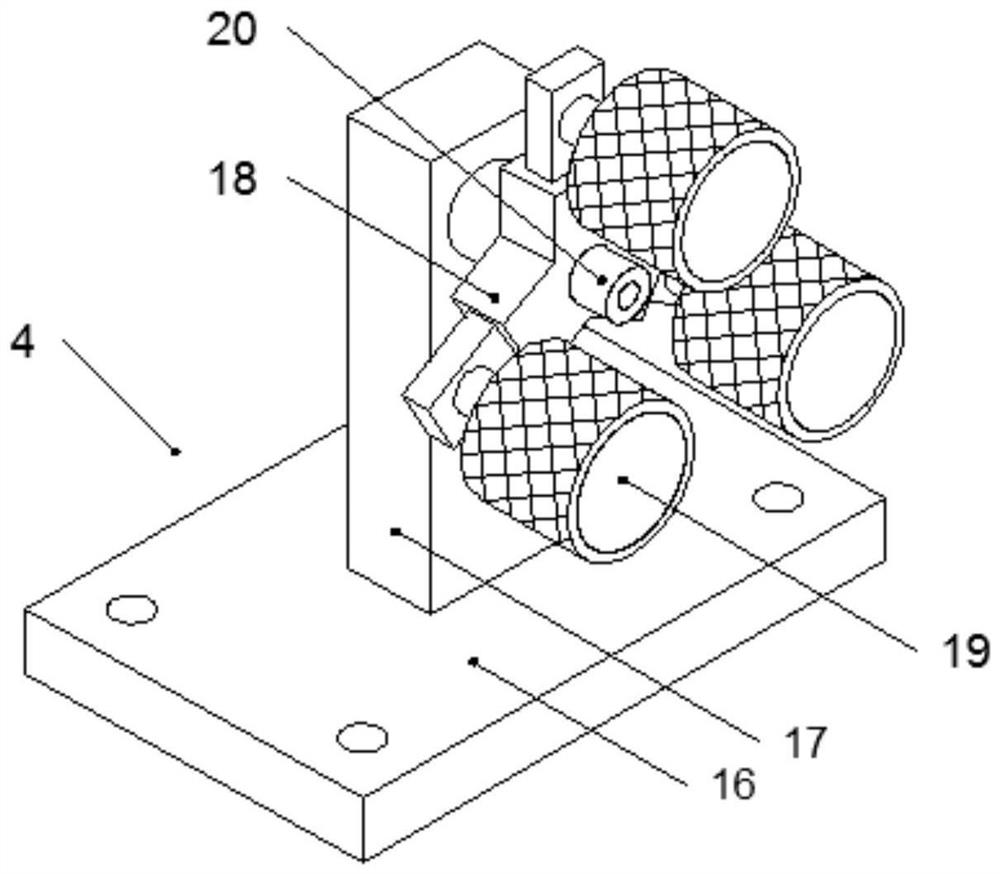

[0020] Example: such as Figure 1-4 As shown, a single crystal silicon rod cutting surface angle detection device of the present invention includes a frame 1, a linear guide rail 2 is fixedly installed on one side of the top of the frame 1, a lead screw 9 is fixedly installed inside the linear guide rail 2, and there are 9 sets of lead screws A slider 10 is provided, the top of the slider 10 is fixedly mounted with a moving fixture 4, the top of the frame 1 is fixedly mounted with a fixed fixture 5 on a side away from the moving fixture 4, and the top of the frame 1 is fixed on a side close to the fixed fixture 5 An angle measuring instrument 6 is installed, a motor 8 is fixedly installed on one side of the frame 1, and a rotating shaft 3 is fixedly installed on a side close to the top of the motor 8 inside the frame 1. The output shaft sleeve of the motor 8 is provided with a driving gear 23, and the rotating shaft 3 A transmission gear 22 is sheathed, and a driven gear 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com