Pure water system for coating cleaning equipment

A coating cleaning and pure water technology, which is applied in liquid cleaning methods, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of poor coating quality, incomplete cleaning, etc., and is conducive to popularization and application , simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to specific embodiments and accompanying drawings to help understand the content of the present invention.

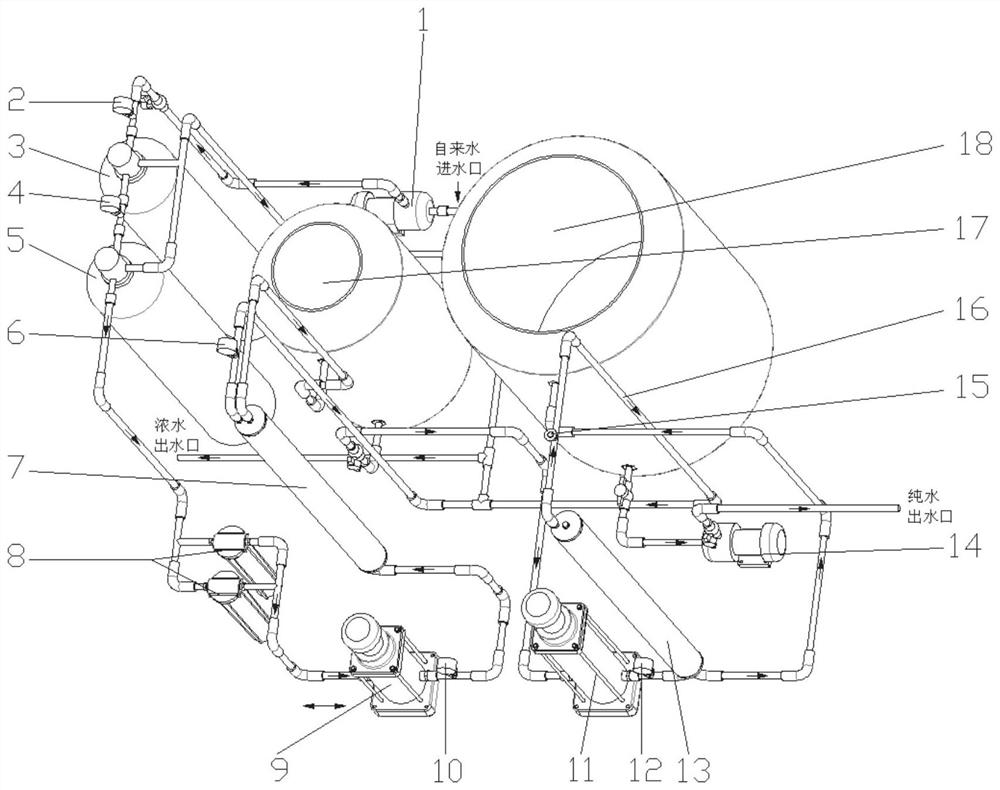

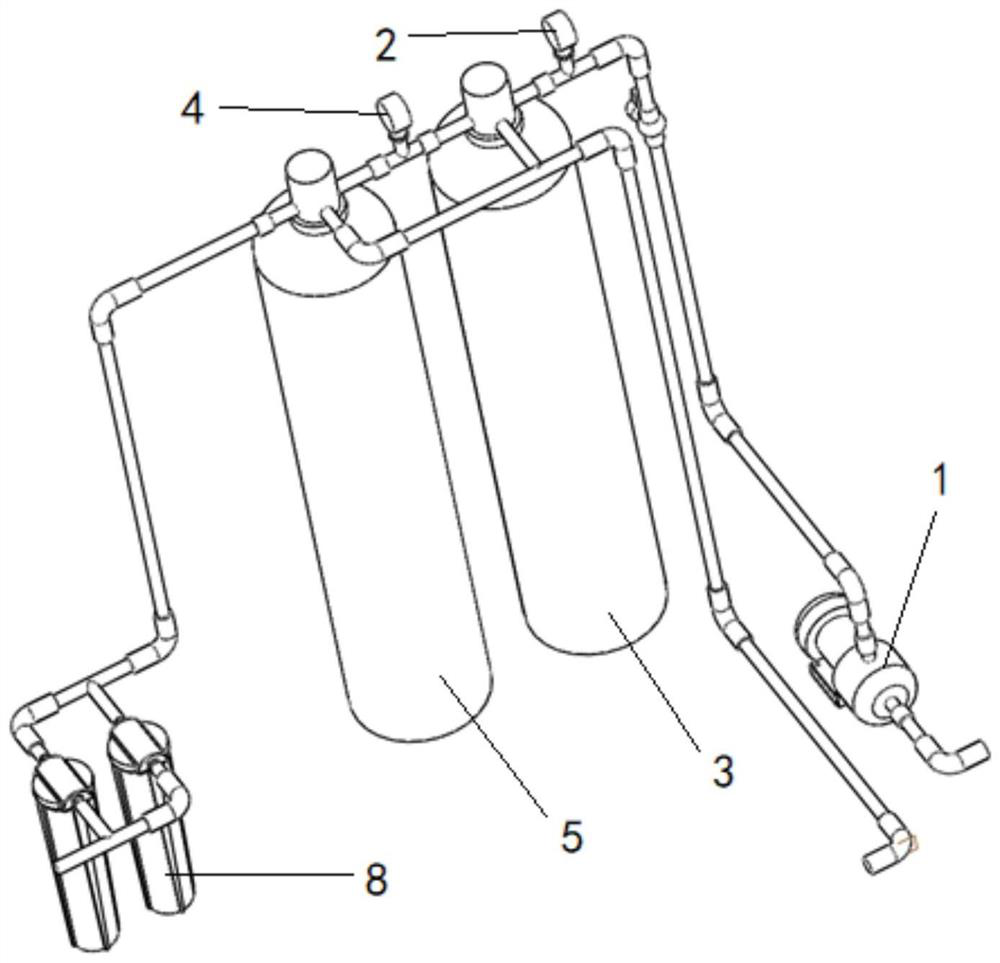

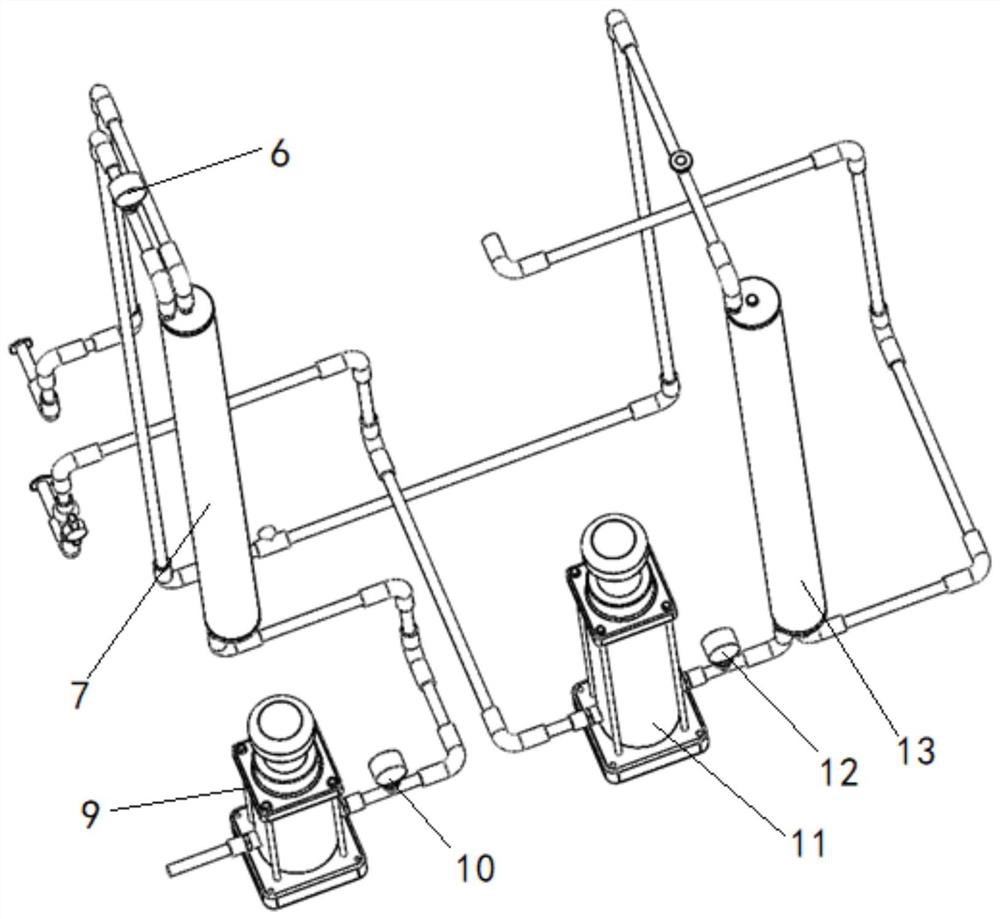

[0022] like Figure 1-3 As shown, it is a schematic diagram of the overall structure of a pure water system for coating cleaning equipment provided by the present invention, a schematic diagram of the installation of a pre-treatment device for concentrated water, and a schematic diagram of the installation of a reverse osmosis membrane. The pure water system for coating cleaning equipment includes concentrated water booster pump 1, pressure gauge 1 2, quartz sand device 3, pressure gauge 2 4, activated carbon device 5, pressure gauge 3 6, reverse osmosis membrane 1 7, filter element Device 8, high pressure pump one 9, pressure gauge four 10, high pressure pump two 11, pressure gauge five 12, reverse osmosis membrane two 13, pure water booster pump 14, pressure control valve 15, water pipe 16, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com