Knitting open-width continuous ultrasonic scouring system and method

An ultrasonic and scouring technology, applied in the open-width field of knitwear, can solve the problems of poor fabric washing effect, long production time, and color difference, and achieve the effect of improving scouring whiteness, increasing contact area, and reducing cloth wrinkle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

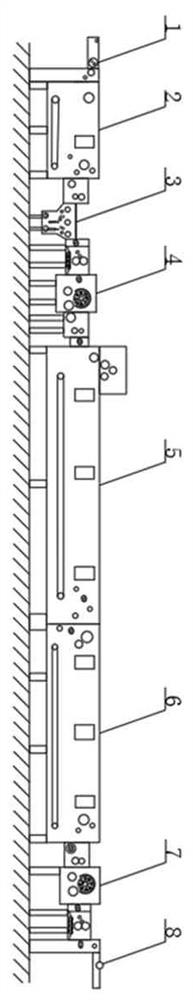

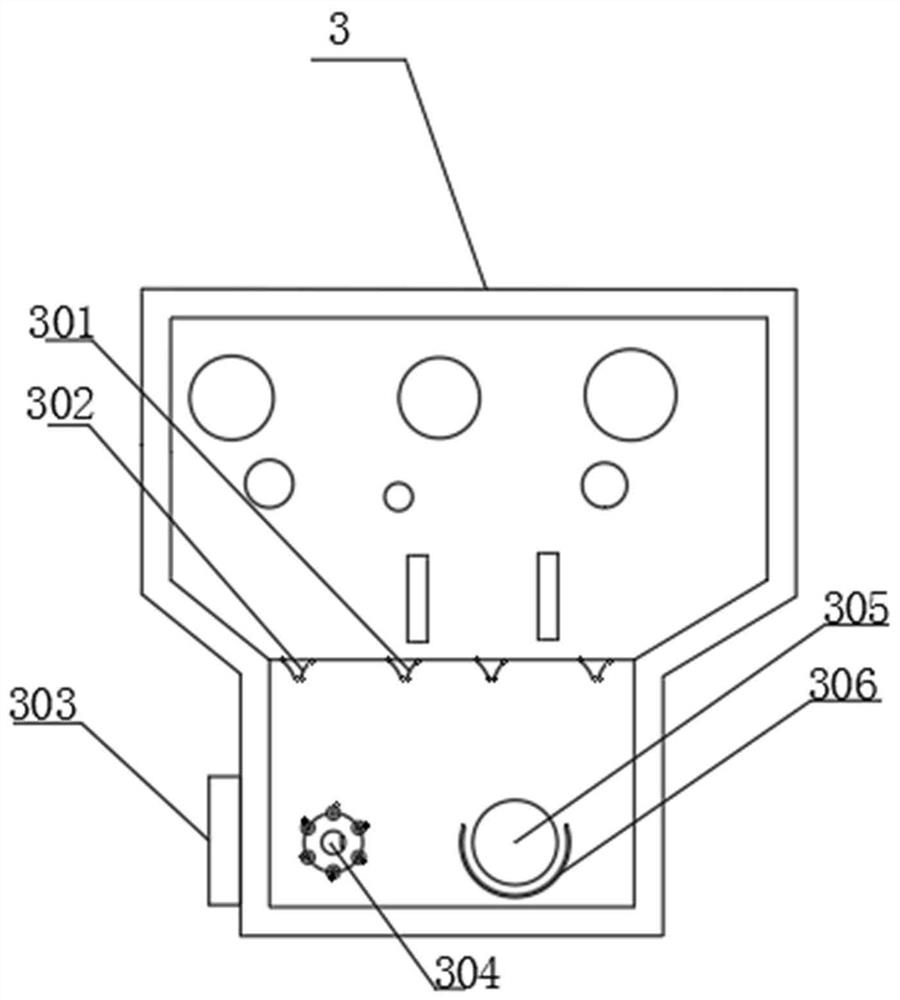

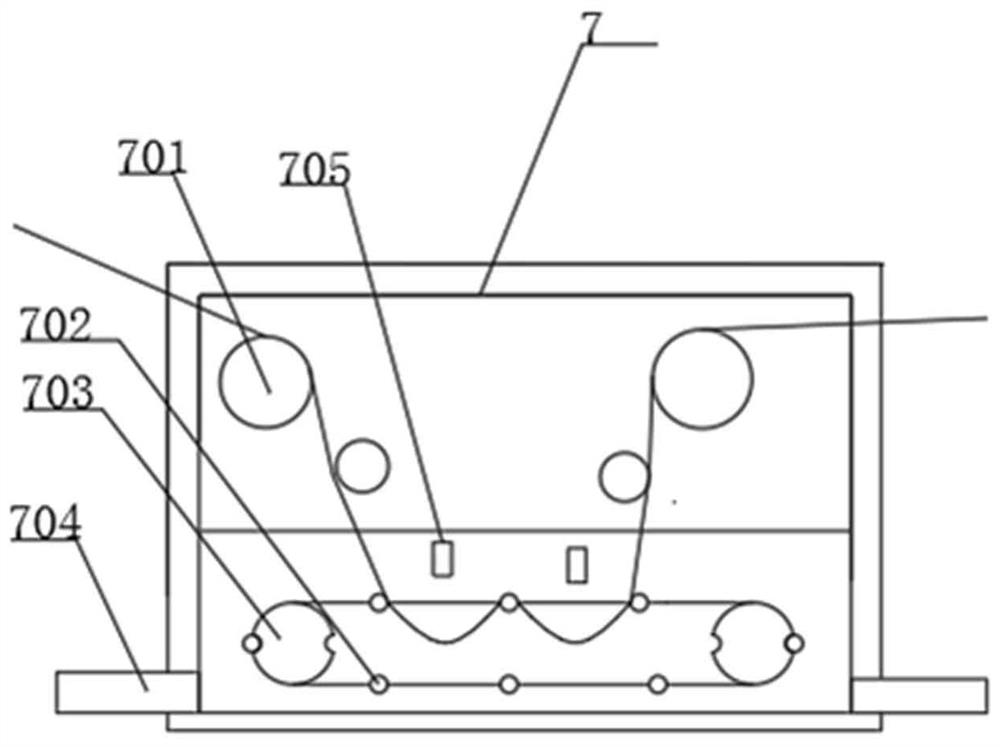

[0038] Such as Figure 1-6 As shown, a knitting open-width continuous ultrasonic scouring system includes a cloth feeding tank (1), a first box for removing ore (2), a material tank (4), a second box of steaming box (5), and a third box Box washing box (6) and cloth outlet chute (8), No. 1 ultrasonic cleaning box (3) is set between the first box demineralization box (2) and material chute (4), the third box washing box (6) and A No. 2 ultrasonic cleaning box (7) is arranged between the cloth outlet slots (8), and a No. 1 ultrasonic transmitter (303) is fixedly installed on the inner side of the No. 1 ultrasonic cleaning box (3). There is a cloth feeding track (302) and multiple cloth output tracks (301) fixedly installed inside, and an inner surface cleaning head (304) is installed inside the No. 1 ultrasonic cleaning box (3) and below the cloth output track (301) And driving wheel (305), the outer surface cleaning cover (306) is installed under the driving wheel (305), and N...

Embodiment 2

[0045] Such as Figure 1-6 Shown, a kind of knitting open-width continuous ultrasonic cooking method, it is applied to knitting open-width continuous ultrasonic cooking system, its specific steps are as follows:

[0046] The first step: configure the base material, the preparation method of the base material: base material concentration degreasing agent 3 g / L, chelating agent 2 g / L, base material amount 1 ton, trough (4) base material: base material needs 400L , Primer concentration: caustic soda 20 g / L, hydrogen peroxide 20 g / L with a concentration of 27%, degreasing agent 2 g / L;

[0047] The second step: configure the trough (4) operating material, the operating material concentration: caustic soda 40 g / L, hydrogen peroxide with a concentration of 27% 40 g / L, degreasing agent 4 g / L;

[0048] Step 3: After the bottom material is prepared, start to heat up. Set the temperature: the first box of demineralization box (2) 60 ° C, the second box of steam box (5) steaming temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com