Infrared imaging non-uniformity intelligent calibration and correction method and system

A non-uniformity correction and non-uniformity technology, which is applied in the field of infrared imaging non-uniformity intelligent calibration and correction, and achieves the effects of less number, less memory, and low time and space complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

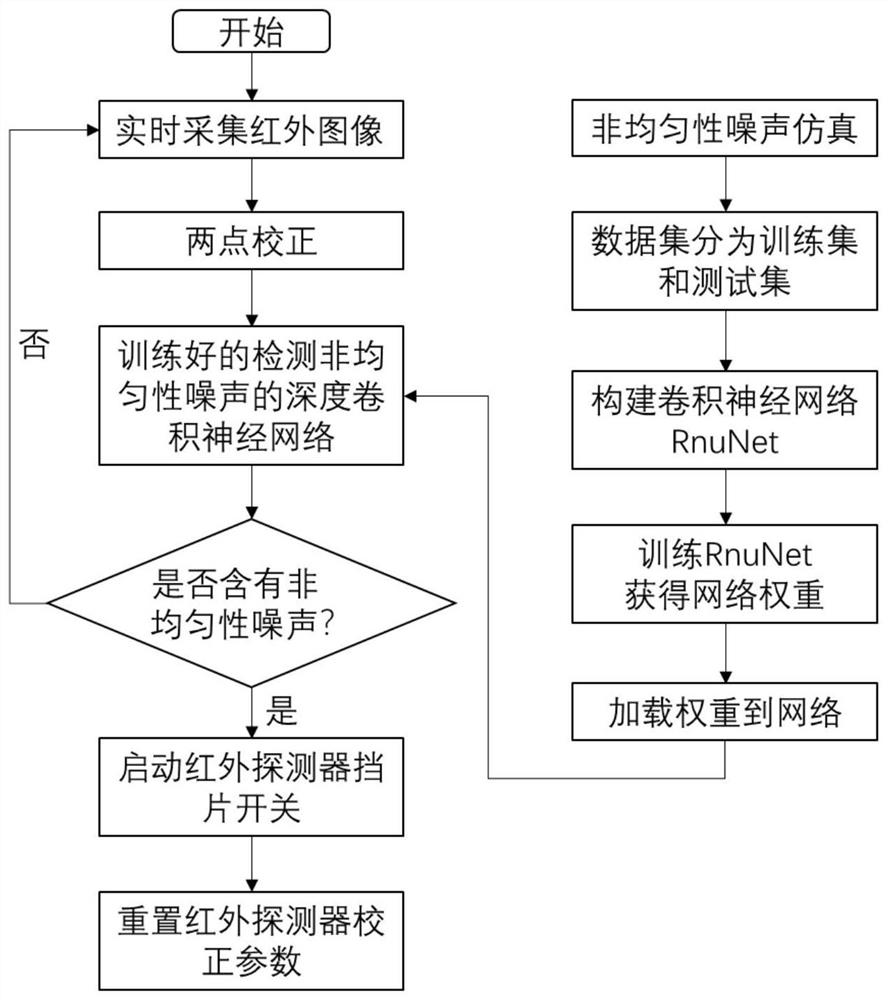

[0054] An intelligent calibration and correction method for infrared imaging non-uniformity, such as figure 1 shown, including the following:

[0055] S1: Perform two-point correction on the currently collected infrared original image to remove multiplicative and additive non-uniformity noise;

[0056] Further, the two-point correction calculation formula is as follows:

[0057] Y ij (n)=K ij (n).X ij (n)+B ij (n)

[0058] Among them, Y ij (n) is the corrected gray value of the two points at the detector pixel (i, j) of the nth frame; X ij (n) is the response value of the detector pixel (i, j) in the nth frame; K ij (n) is the gain correction value of the detector pixel (i, j) in the nth frame; B ij (n) is the offset correction value of the detector pixel (i, j) in the nth frame;

[0059] Gain and offset correction values can be expressed as:

[0060]

[0061]

[0062] Among them, T H and T L Indicates high and low temperature points; with Respectively...

Embodiment 2

[0084] A calibration-based intelligent infrared imaging non-uniformity correction system, such as Figure 4 As shown, it includes an infrared optical system, an infrared detector and a radiation shield, and also includes an infrared image processing system. The infrared image processing system includes a non-uniformity correction unit, a non-uniformity neural network detection unit, a radiation shield control unit, and an infrared detection The device obtains the infrared radiation analog signal of the target scene in real time through the infrared optical system, and transmits it to the infrared image processing system after analog-to-digital conversion. The infrared image processing system first performs two-point correction on the input infrared radiation digital signal through the non-uniformity correction unit. , and then sent to the non-uniform neural network detection unit to detect whether the two-point corrected image contains non-uniform noise, if it contains non-unif...

Embodiment 3

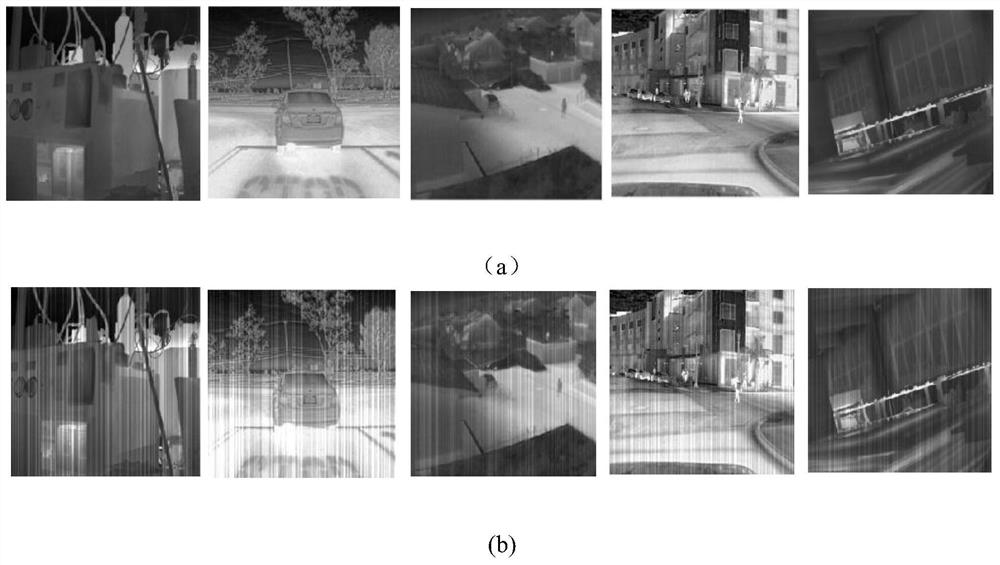

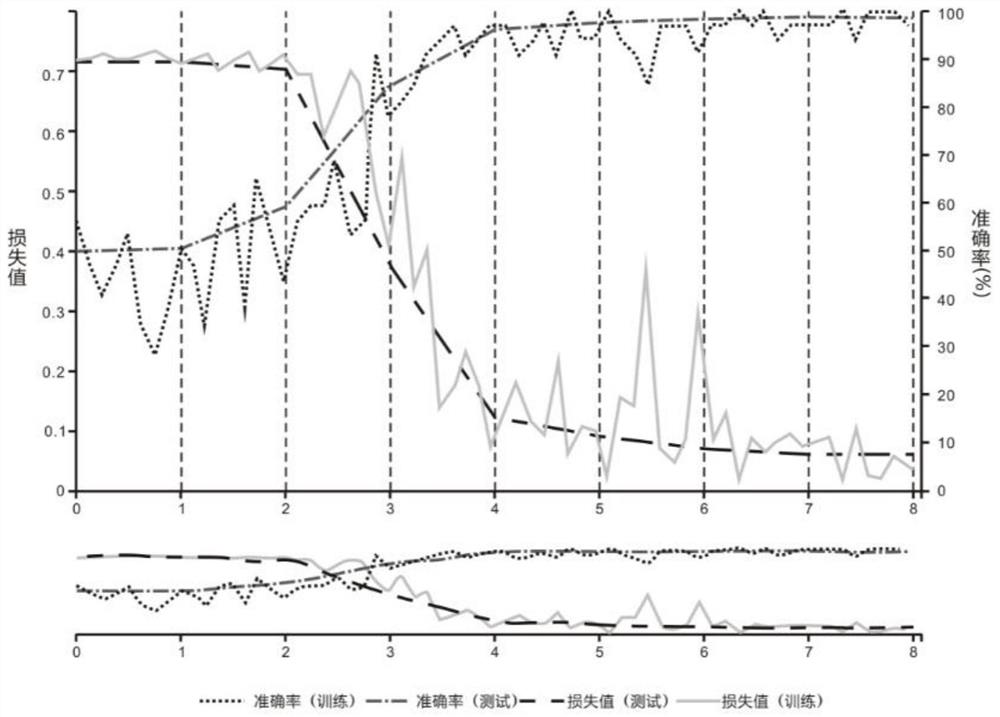

[0099] In the detection non-uniformity noise convolutional neural network RnuNet among the present invention, the network structure is specifically described as follows:

[0100] The RnuNet of the present invention is composed of 5 convolutional layers, 2 fully connected layers and 1 output layer. The five convolutional layers are respectively denoted as C1, C2, C3, C4 and C5; the two fully connected layers are denoted as FC6 and FC7 respectively.

[0101] The input image size is 227x227. The 5 convolution layers use convolution kernels with sizes of 11x11, 5×5 and 3×3 for convolution operations, among which the C1 layer uses 11x11 convolution kernels, and the C2 layer uses 5×5 convolution Kernel, layers C3 to C5 use 3×3 convolution kernels. The number of convolution kernels C1-C5 layers are 96, 256, 256, 256 and 128 respectively. The five convolution layers respectively input the feature maps obtained after convolution to the ReLU function for activation. The C1 layer, C2 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com