Film quality detection method and device, electronic equipment and storage medium

A quality inspection and film technology, applied in the field of film quality control, can solve the problems of low film quality inspection accuracy, lack of quantitative indicators for evaluation standards, and complex inspection procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

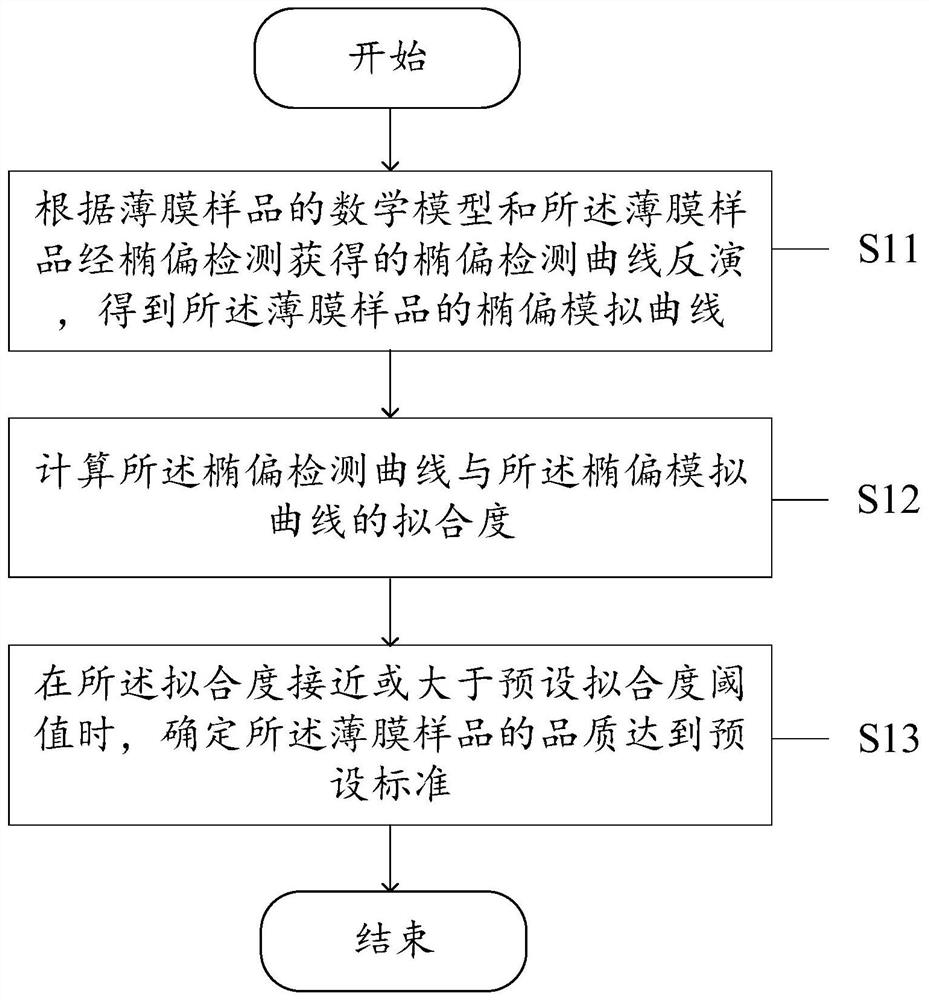

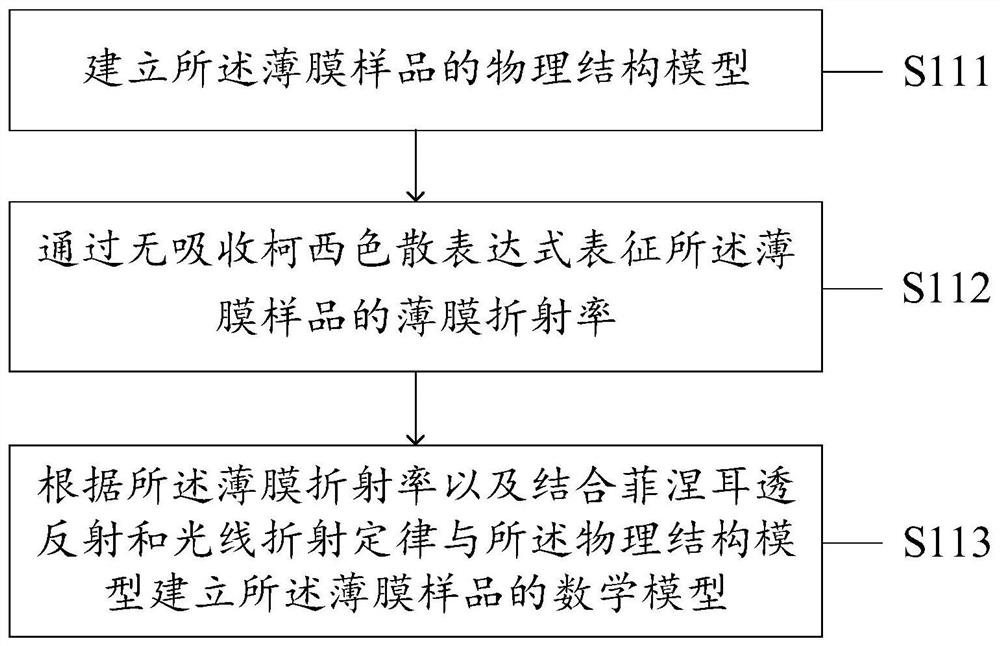

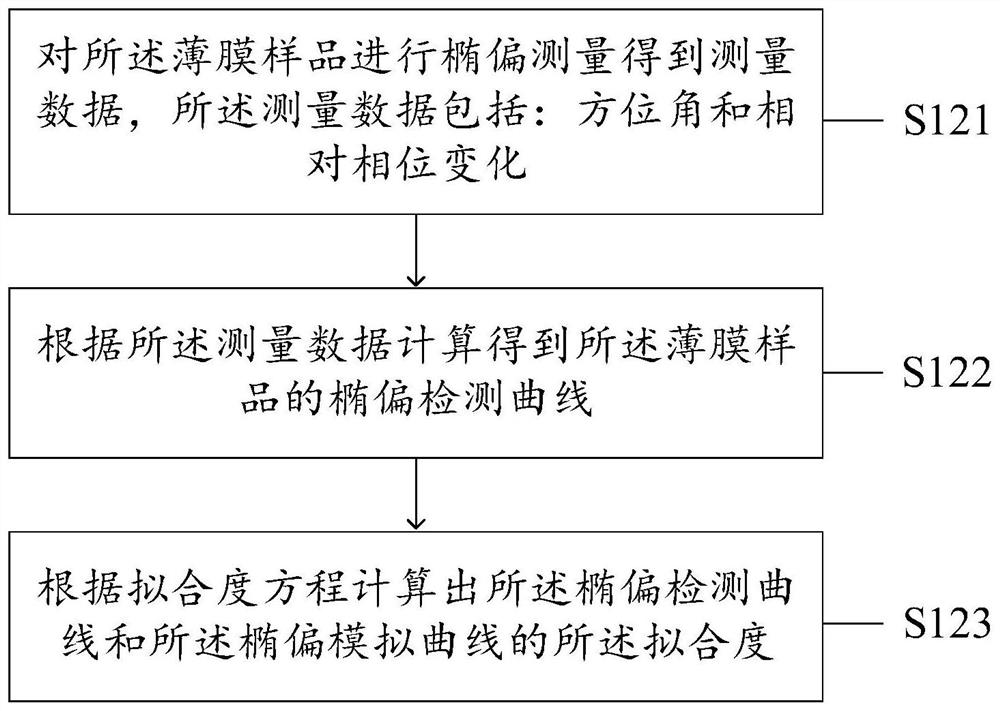

[0065] Please see figure 1 , figure 1 A schematic diagram of a film quality detection method provided in the embodiment of the present application, the method includes:

[0066] In step S11, according to the mathematical model of the thin film sample and the ellipsometric detection curve obtained by the thin film sample through ellipsometric detection, the ellipsometric simulation curve of the thin film sample is obtained by inversion.

[0067] Among them, the thin film sample can be an optical thin film, and the intrinsic refractive index dispersion expression of the thin film material can be used as the characteristic parameter, and the ellipsometric detection of the thin film sample is carried out by an ellipsometer, and the ellipsometric The detection curve is obtained by inverting the ellipso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com