Manufacturing method of electrode system of electrochemical testing system

A technology for testing systems and manufacturing methods, applied in the direction of material electrochemical variables, etc., can solve problems such as complex manufacturing process, easy bursting of corundum casing, solid salt corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

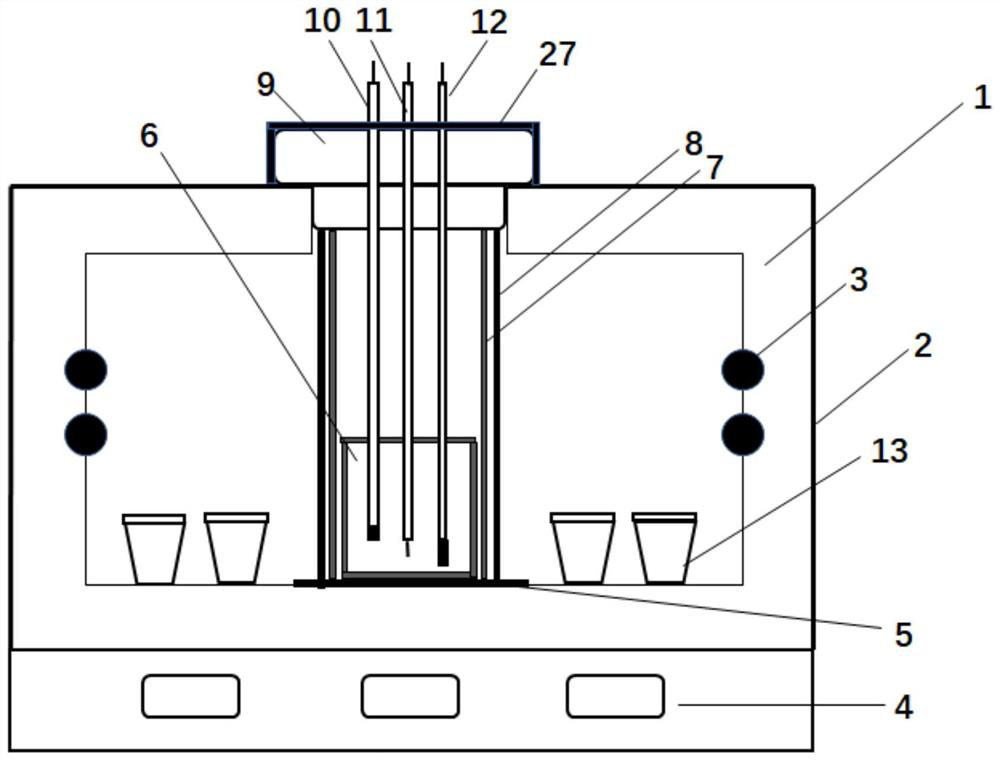

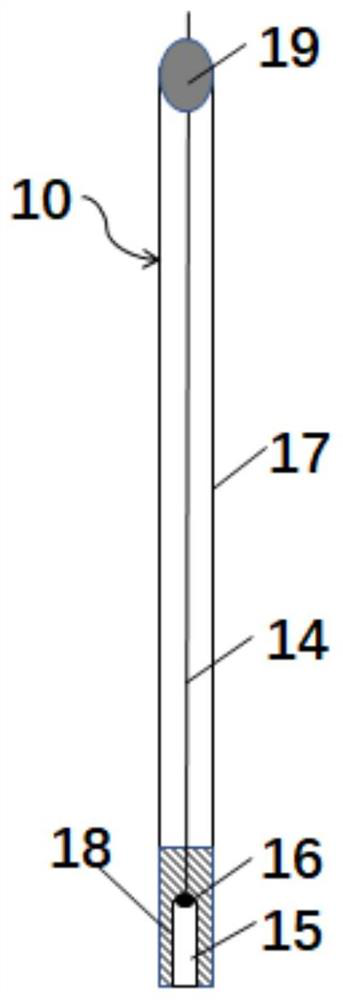

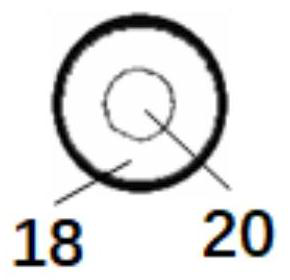

[0047] Exemplary embodiments of the present application are described below with reference to the accompanying drawings. It should be understood that these specific descriptions are only used to teach those skilled in the art how to implement the present application, but are not intended to exhaust all possible ways of the present application, nor are they used to limit the scope of the present application.

[0048] The present application provides a system capable of carrying out molten salt corrosion experiments on metals and high-temperature resistant coatings and performing electrochemical tests on corrosion layers. The system can be used to study the electrochemical corrosion behavior of metals and coatings in high-temperature molten salt media, and then reasonably explain the high-temperature hot corrosion mechanism of metals and coatings. It is understood that the metals described in this application include pure metals as well as alloys.

[0049] Such as figure 1 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com